Affordable and clean energy

At Schlüter-Systems, efficient energy management is playing an increasingly important role. This is how we contribute to making the use of energy in the company more conscious.

Industry with responsibility: increasing efficiency, reducing emissions.

Economic success and environmentally friendly actions are not mutually exclusive – on the contrary: for Schlüter-Systems, the two are inextricably linked. As a medium-sized company, we know how important it is to use energy and resources responsibly. That is why we are committed to consistent energy management. Our guidelines: analysing, reducing, replacing, compensating. This is how we contribute to a worthwhile future and take responsibility out of a sense of conviction.

Systematically recorded, efficiently managed: smart energy management

Energy management begins with transparency. Since 2015, we have digitally recorded our electricity, gas and water consumption – using a visualisation tool that provides clear insights into our energy flows. The data we acquire is firmly integrated in our production control system. This allows us to identify potential savings at an early stage and make informed decisions for greater efficiency.

Since the system was introduced, we have been continuously increasing the amount of data collected on our campus. Around 70 percent of the current consumption flows can already be precisely mapped. Our aim: to be able to comprehensively track all energy flows across the entire company premises.

The first step towards saving energy is to record and analyse your own energy consumption.

This is how we already use energy efficiently:

Verified sustainability: Purchasing green electricity

2,263 tonnes CO2 savings

(as of 2023)

100 percent electricity from hydroelectric power

(Iserlohner Heide headquarters)

As a global player of the building materials industry, our production is associated with a high level of energy use. At our Iserlohn headquarters alone – our central production site – the annual electricity consumption is around 5.5 million kilowatt hours.

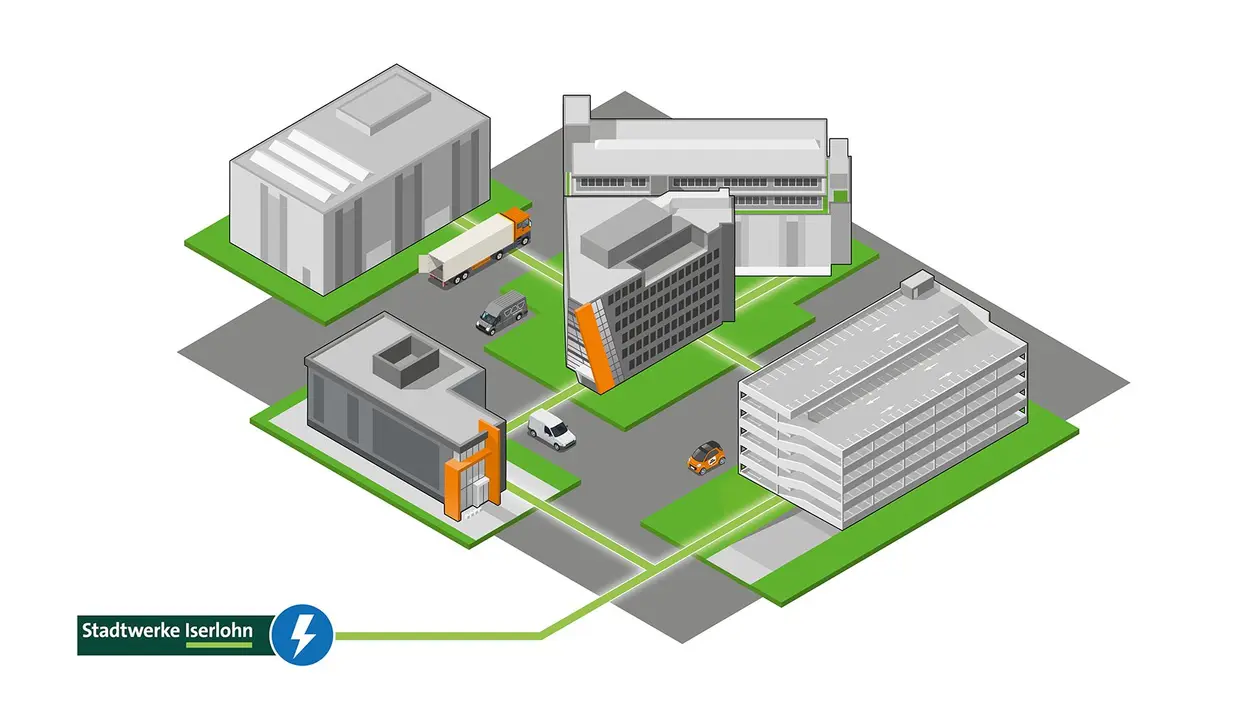

These are figures that call for a sense of responsibility. That is why we are continuously stepping up our use of renewable energies. One important step: : Since 2024, our company campus in Iserlohner Heide has been supplied exclusively with renewable energy from the region.

Certified climate-friendly: TÜV Nord confirms that the electricity supplied by Stadtwerke Iserlohn is generated entirely from hydroelectric power, meaning that production is CO2-neutral. In 2023, the use of green electricity meant that we were able to save 2,263 tonnes of CO₂ – a substantial contribution to the reduction of industrial emissions and a clear sign of responsible action.

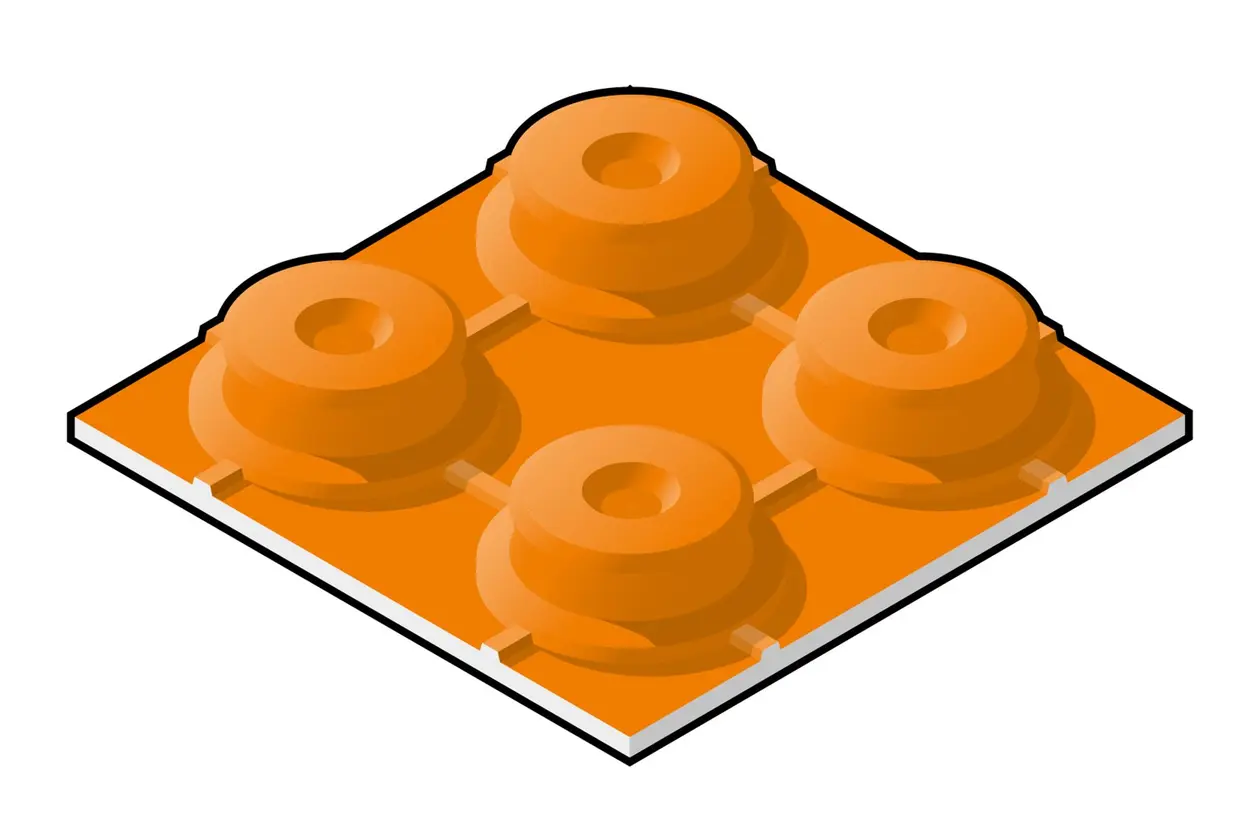

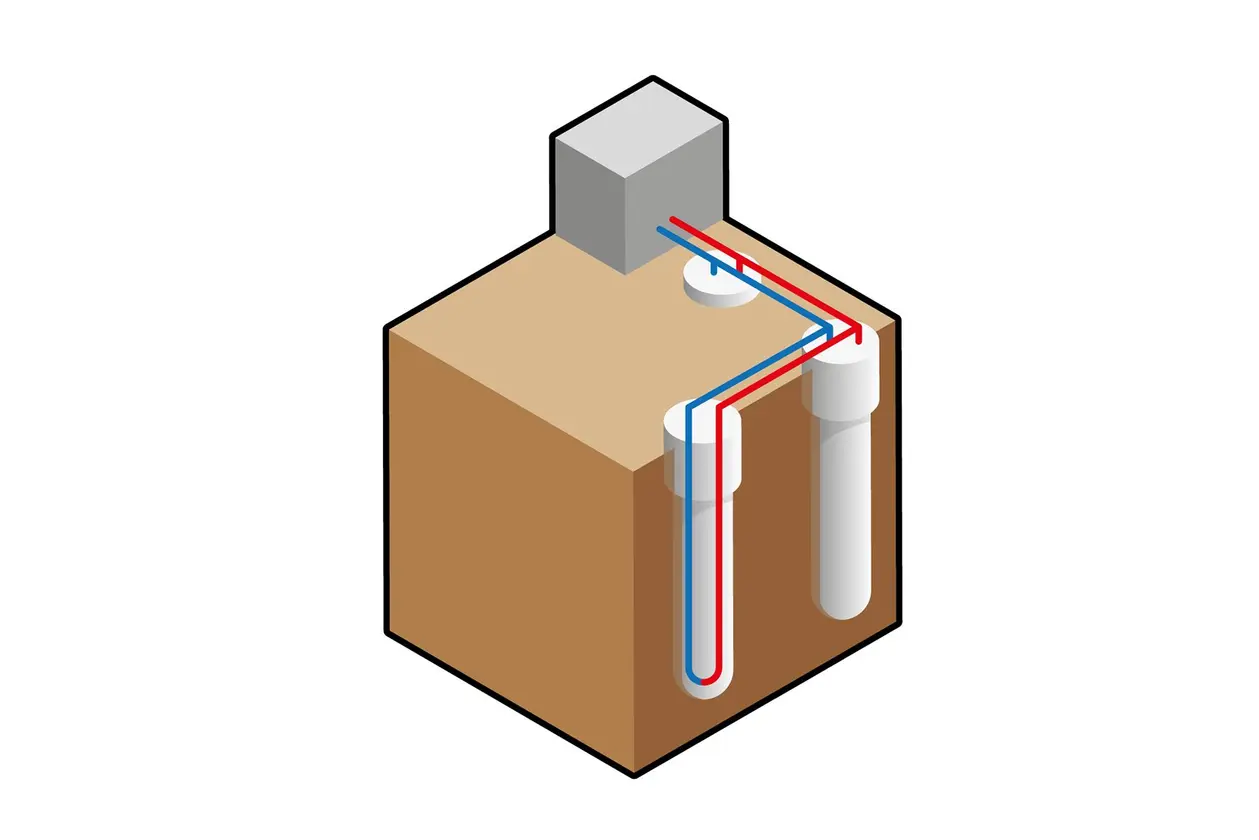

Temperature control by circulation: All-round efficiency with geothermal energy

IT air conditioning by means of cooling

Heating system operation via geothermal energy

Geothermal energy is a system that intelligently combines heating and cooling for a forward-looking form of building temperature control. The heart of the system is a large-scale geothermal probe field directly on the company campus. The highly efficient system uses the circulation principle, saves electricity and shows how technological innovation can be combined with ecological responsibility.

Since 2019, we have had one of the most modern and energy-efficient computer centres in the region – purely electric, highly redundant and designed for maximum operational security. The sensitive IT infrastructure is air-conditioned by a geothermal cooling system.

What's more, the geothermal probes do more than just simply cool: they also supply our office buildings with heat by feeding heat pumps – with no need of electricity-intensive compressors. One system, two functions, one clear aim: the smart use of energy.

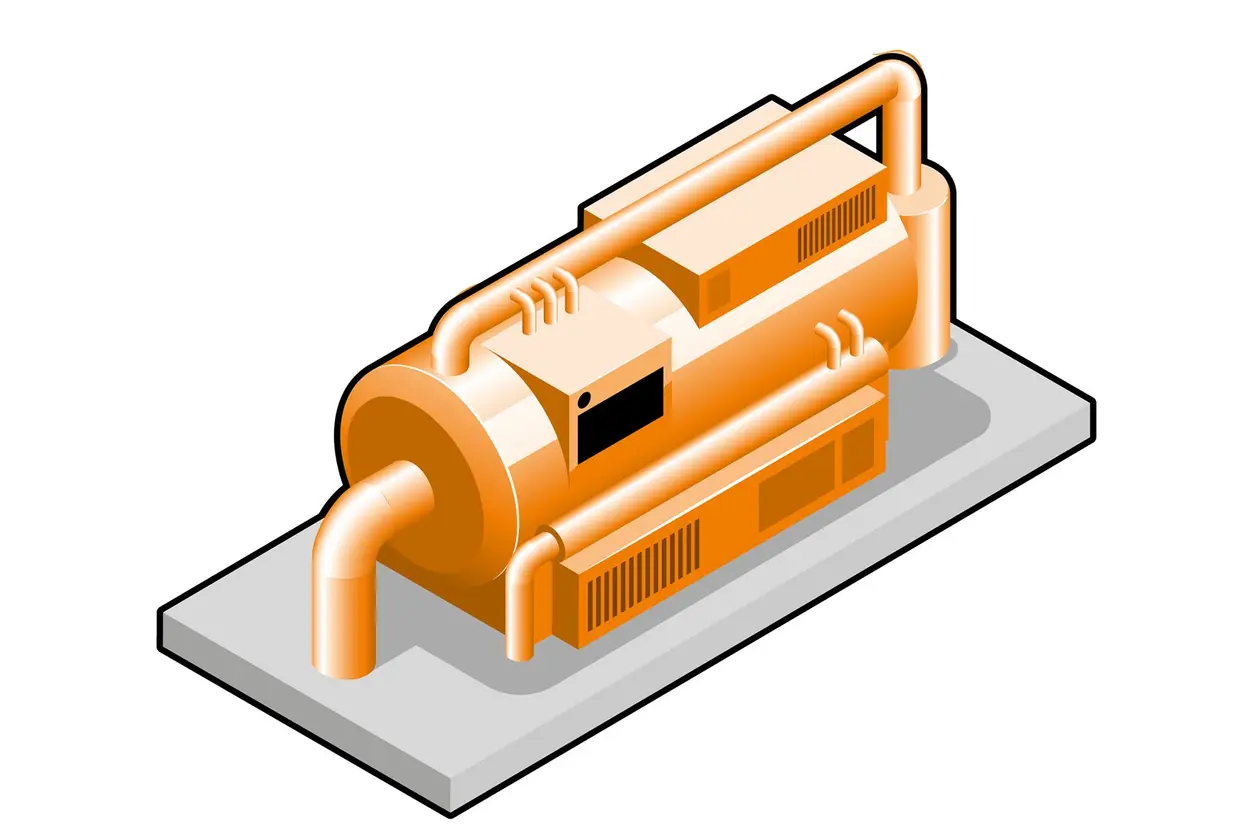

Self-sufficient and efficient: combined supply with CHP

67,000 kWh per year

due to CHP

Doubly clever:

Combined heat and power generation

Powered up: Electrical power in the vehicle fleet

26,000 kg CO2 savings

(as of 2024)

36 electric charging columns

As a medium-sized company, we are actively participating in the transition to electromobility. From compact apprentice runabouts to fully equipped craftsmen's vehicles and modern company cars – our fleet is paving the way towards a lower-emission future, kilometre by kilometre.

In 2024 alone, we were able to achieve CO2 savings of between 22,000 and 28,000 kilogrammes. Fuel costs are also significantly reduced at the same time – a benefit that is good for the environment as well as the company.

Clean driving, made possible by clean charging? Visitors and employees alike benefit from our commitment towards a new approach to mobility: They can recharge their vehicles conveniently and in an environmentally friendly way at our electric charging columns.