Suitable covering materials for floor heating systems

Ceramic tiles, parquet, laminate or carpeting - which covering types are best suited for a floor heating system?

Which covering types are best suited for a floor heating system?

Ceramic tiles, marble and other natural stone materials are ideally suited as coverings for floor heating systems. However, parquet, laminate or even carpeting can also be considered for such use. In addition, the right floor assembly plays an important role for optimal heat dissipation. The following explains what to look out for in the floor covering and covering assembly of your new floor heating system.

Ceramic or natural stone tiles are the first choice for radiant panel heating systems due to their excellent thermal conductivity. They heat up quickly and evenly and have the lowest thermal resistance. Accordingly, tiles quickly transfer heat to room air. They also offer an excellent thermal storage volume to keep the temperature in your space constant.

Since tiles excel at transferring heat, they only have to be heated up to a few degrees above the actual room temperature. Once the room and floor temperature are the same, the heat transfer stops. This is also referred to as a self-regulation effect.

Although coverings made of tile or natural stone are ideally suited for the efficient use of a floor heating system, you can of course also install other coverings such as carpet or laminate on our surface heating systems. That means that they are (virtually) no limits to designing your floor.

When selecting your floor covering, keep in mind that coverings differ in their capacity to transfer warmth radiating from the heating system.

Many floor covering manufacturers offer product variants that are optimised for use with radiant panel heating systems. Make sure to look for the corresponding labels. In addition to tile and natural stone, you can select the following floor options:

Parquet

Laminate

Textile coverings / carpeting

PVC / Vinyl

Linoleum

Overview of thermal conductivity for various floor coverings

| Floor covering | Thickness in mm | Thermal conductivity in W/(mK) | Thermal resistance in m²K/W |

|---|---|---|---|

| Marble | 12 | 2.1 | 0.0057 |

| Concrete blocks | 12 | 2.1 | 0.0057 |

| Natural stone pavers | 12 | 1.2 | 0.010 |

| Ceramic tiles | 13 | 1.05 | 0.012 |

| Fibre-bonded covering | 6.5 | 0.54 | 0.12 |

| Synthetic covering | 3 | 0.23 | 0.03 |

| Mosaic parquet (oak) | 8 | 0.21 | 0.038 |

| Strip parquet | 16 | 0.21 | 0.08 |

| PVC coverings or carrier materials | 2 | 0.2 | 0.010 |

| Laminate | 9 | 0.17 | 0.05 |

| Linoleum | 2.5 | 0.17 | 0.015 |

| Multi-layer parquet | 11–14 | 0.09–0.12 | 0.03–0.15 |

| Carpet | N/A | 0.05–0.15 | 0.07–0.017 |

Source: BVF – German Association for Area Heating Systems

Covering and floor assembly

Conventional floor heating systems frequently develop buckling and cracks in the screed or the floor covering - primarily because the screed and the floor covering have different heat expansion characteristics in response to temperature changes.

The relatively large screed volume of conventional systems has the disadvantage that a large amount of heating energy has to be supplied and stored. Conventional floor heating systems therefore are slow to respond to temperature changes.

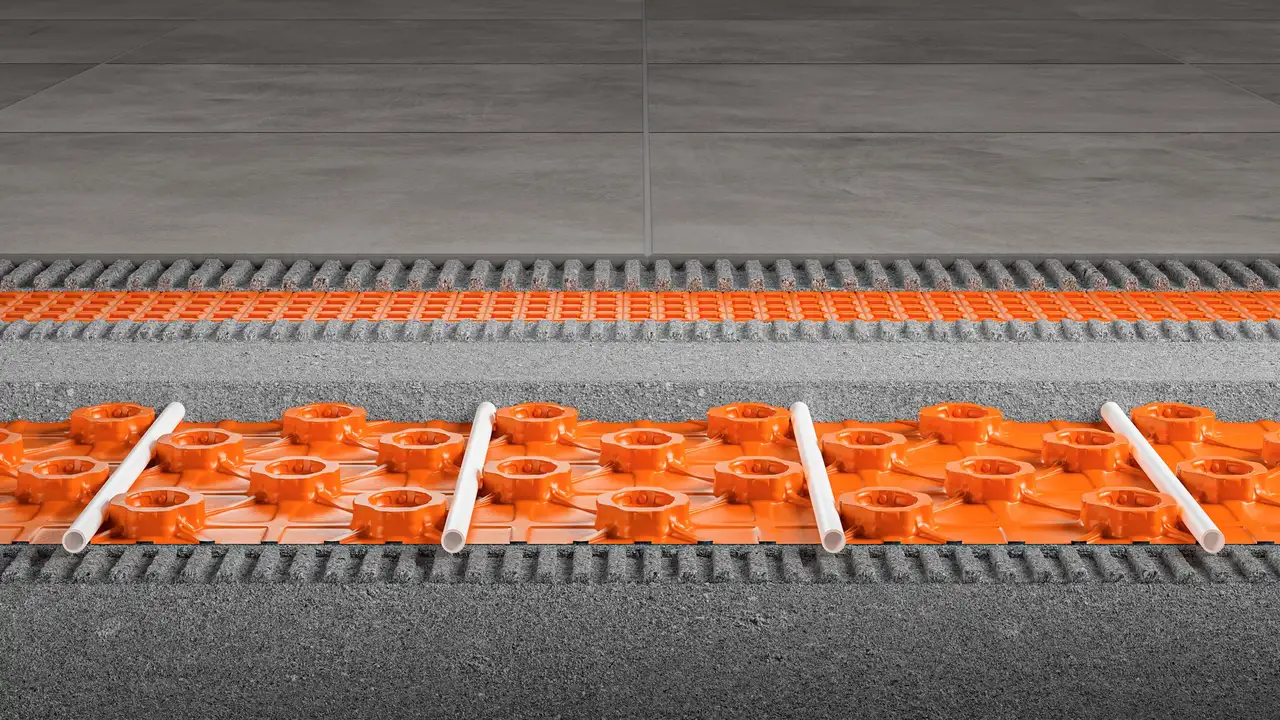

The integrated Schlüter-BEKOTEC-THERM system with its particularly low assembly height solves all of these problems. The system is based on a thin screed, which is applied over the studded BEKOTEC panels and reduces the shrinkage tensions of the screed surface in the studded pattern. If the uncoupling mats Schlüter-DITRA, DITRA-DRAIN 4 or DITRA-HEAT are used, tiles or natural stone panels can be installed as soon as the screed is ready to bear weight. Our THERM heating components are an exact match for BEKOTEC as a comprehensive system solution, from the heating circuit distributor to the actuator and electronic temperature control up to the high-quality heating pipes. The relatively small amount of screed and the proximity of the heating pipes to the surface create a highly responsive floor heating system.

Floor assembly heights with BEKOTEC studded panels

| Studded panel | Assembly height in mm | Particularly suitable for: |

|---|---|---|

| Schlüter-BEKOTEC-EN-FI | 61 | New construction |

| Schlüter-BEKOTEC-EN | 52 | New construction |

| Schlüter-BEKOTEC-EN-F | 31 | New construction |

| Schlüter-BEKOTEC-EN-FK | 20 | Existing structure |

| Schlüter-BEKOTEC-EN-FTS | 31 | Existing structure |

10 strong arguments for floor heating systems with tile covering

Warm: The insulation and floor heating system create a pleasant room environment.

Exclusive: Thanks to individual installation patterns, there are countless design options for tile coverings.

Quiet: Tiles and sound insulation block out the noise.

Resistant to wear: tiles show virtually no wear and tear.

Hygienic: Dust mites or contaminants don't stand a chance on ceramic tiles.

Durable: Properly installed tile coverings can last for centuries.

Fireproof: Neither cigarette ashes nor open flame can harm ceramic tiles.

Homely: Tiles are a perfect fit for the entire house, from the attic to the basement.

Easy to care for: Dirt on your shoes or food crumbs: water is usually sufficient for cleaning.

Reasonably priced: Tile coverings are durable, sanitary and easy to care for.