Schlüter-TROBA

This long-lasting surface drainage sheet is laid between the waterproofing and the crushed stone layer and provides dome-like drainage channels that allow any seepage water to be reliably drained away.

Lay your terrace pavers without mortar: the Schlüter-TROBA system solutions give your pavers a secure hold and ensure reliable drainage.

No mortar, no adhesive, no joint sealant: where terrace pavers are installed floating or without bonding, they rest on a crushed stone layer or another suitable support base such as paver supports or mortar rings. The type of installation has many advantages, depending on the design – and goes hand-in-hand with our Schlüter-TROBA system solutions.

The system solutions of the Schlüter-TROBA series offer innovative products for all who are involved in professional surfacing in gardens and landscaping.

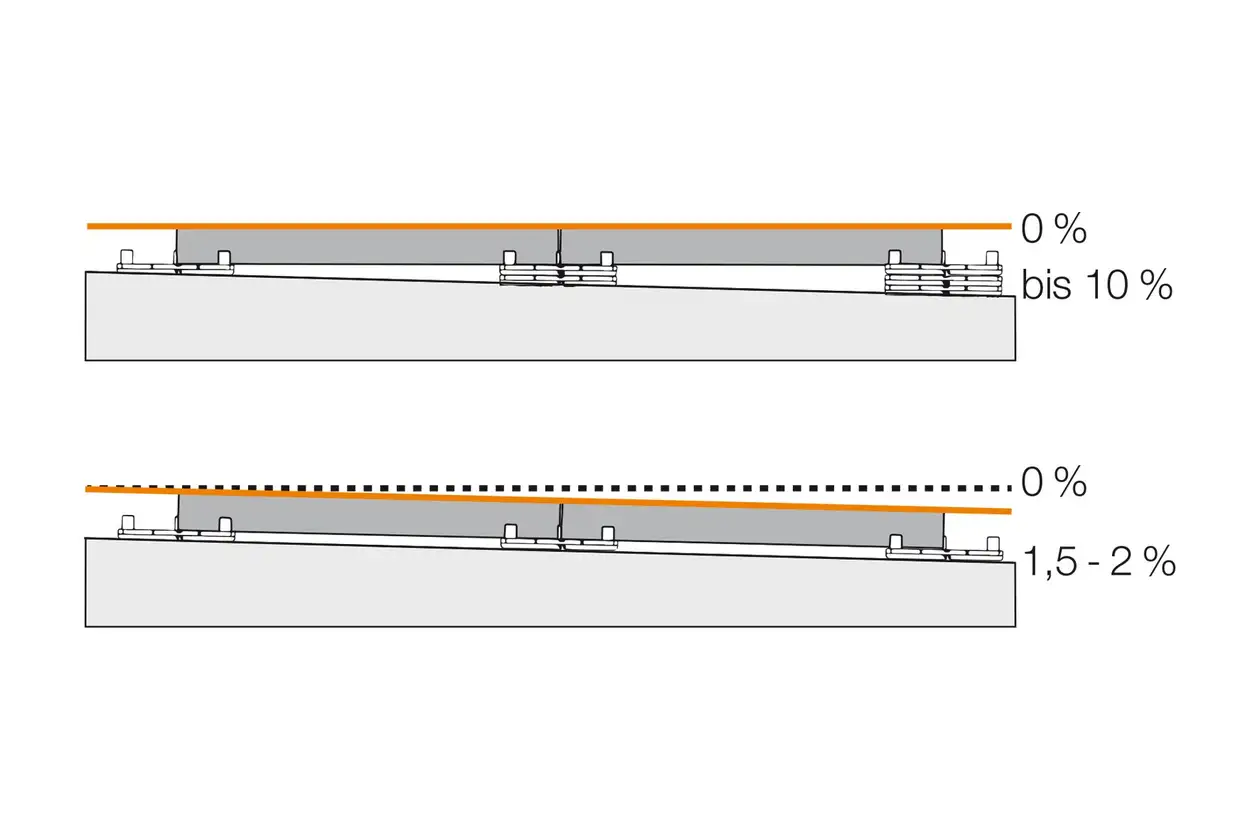

Components of the TROBA-LEVEL series can be combined in various ways and can level slopes of up to 10% with millimetre precision.

The system for an optimal edge solution: unbonded pavers have been combined with the TROBA-LINE-TLK-E gravel retaining angle on this border.

Unbonded or floating installation has no fixed bond between the surface pavers and the substructure. Instead, the pavers are placed either unbonded or resting on a suitable substrate, either by only their corners or over their whole surface, depending on the design. This installation method is highly suitable where outdoor ceramic or natural stone is desired on terraces, roof terraces or balconies. The result is a covering with open joints that can be lifted again at any time. Surface water flows down through the joints to the waterproofing level and from there is guided away via a sloped surface drainage system. A decisive factor for waterproofing and drainage is that the substrate is prepared professionally.

Three potential construction structures are available for installing a floating cover, depending on the substrate situation:

In this structure the pavers lie directly on a layer of bulking material with a slope of 2%.

In this construction, mortar or formwork rings are positioned at the joint intersections and in some cases at the centre of each paver.

In this version the pavers rest on height-adjustable paver supports made of a long-life special plastic.

With unbonded installation on crushed stone, the pavers are laid directly on a bedding layer of fine grit. The substructure generally consists of a base course built with sufficient slope and waterproofing. The base course must be capable of drainage and sufficiently deep to protect the cover from frost damage.

This method of installation is comparatively simple and low-cost and is often used in terraces and road or path construction for private areas. Since the pavers rest on the crushed stone layer without a fixed bond to the substrate, this method is particularly suitable for heavy cover materials such as natural stone, whose heavy dead weight provide the necessary stability. To secure the cover against horizontal creep, the use of tile and paver spacers such as the Schlüter-TROBA-ZFK is additionally recommended.

If a balcony or roof terrace is covered in this way, the weight-bearing structure must be protected against water penetration by a DIN 18531-compliant structural waterproofing. In such cases, Schlüter-TROBA is laid as a protective and separating layer between the waterproofing and the bedding layer. This protects the waterproofing from mechanical damage while also ensuring that seepage water is quickly and reliably drained away so that no 'ice concrete' can form.

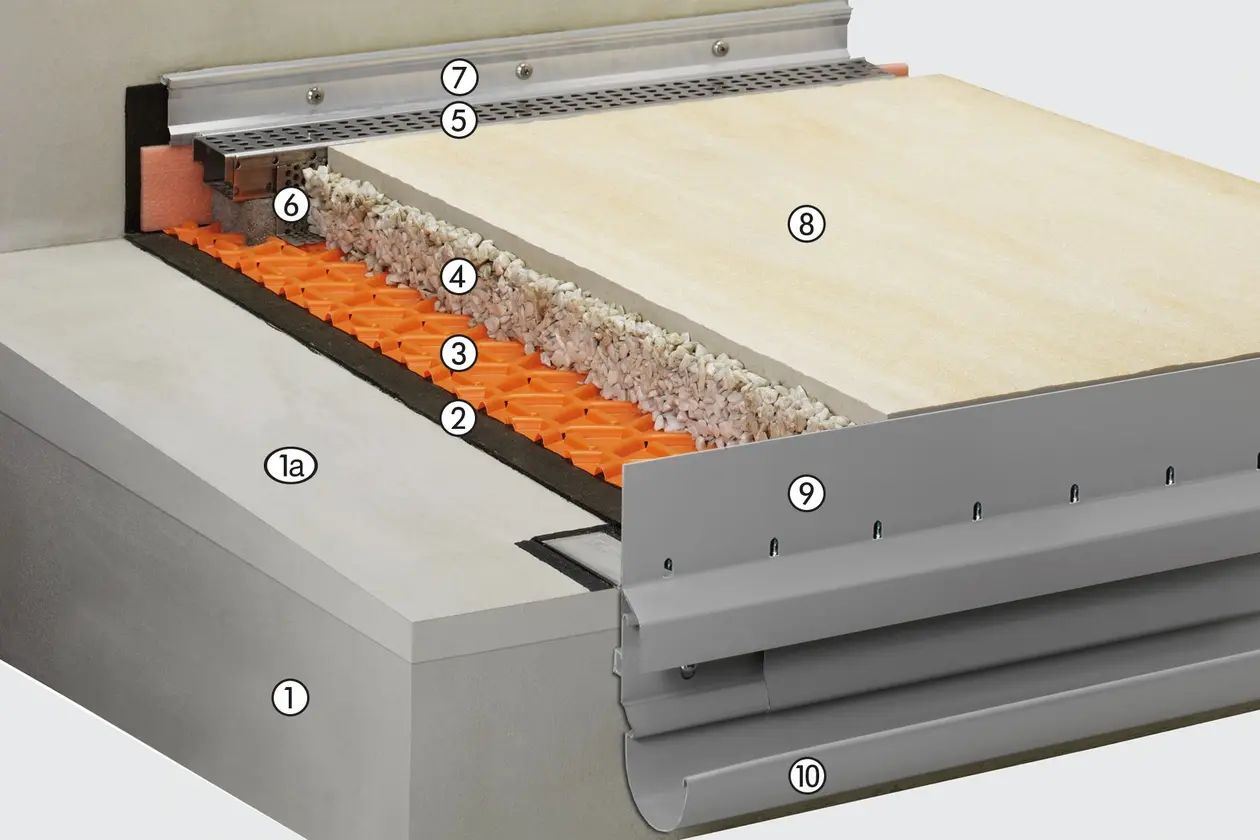

On the cantilevered concrete slab (1) a sloped screed (1a) is added with a slope of 1.5-2% for drainage.

A structural waterproofing element compliant with DIN 18531 is placed over the sloped screed.

To protect the waterproofing and to ensure effective removal of seepage water, the Schlüter-TROBA drainage sheet is placed between the waterproofing and the bedding layer.

On top of the drainage sheet, the bedding layer of crushed stone is added – the edges of which should be bonded.

To facilitate drainage when adjoining door elements at a low height, the Schlüter-TROBA-LINE drainage channel is used.

Along with the drainage channel, the Schlüter-TROBA-LINE-TLK-E gravel retaining angle is also fitted and combined with edge insulating strips at the rear.

A capping strip covers the edge of the wall where it meets the waterproofing.

The self-supporting terrace pavers are laid on the bedding layer and tapped into place. To maintain a consistent joint width and to prevent horizontal creepage, we recommend the use of the Schlüter-TROBA-ZFK tile and paver spacers.

The Schlüter-BARA-RKLT makes a suitable finishing profile for unbonded coverings. Its angled edge profile is made in colour-coated aluminium and features drainage openings.

Attached to the T-shaped profile chamber of the Schlüter-BARA-RKLT is the Schlüter-BARIN gutter system, which, combined with the drainage holes, ensures reliable drainage of seepage water.

In this method of installation, large-format, self-supporting pavers are attached at the joint intersections – and, if loading is high, also at the centre of each tile – with mortar.

For low structures formwork rings such as the Schlüter-TROBA-STELZ-DR serve as installation aids; these are placed at the joint intersections and filled with thin-bed mortar. The mortar should protrude a little beyond the rim to ensure that the paver element can be tapped into the correct height position. Alternatively, the formwork rings can be used simply as mould templates for the thin-bed mortar and re-used once the mortar has set.

For structures with more height, mortar rings such as the Schlüter-TROBA-STELZ-MR can be filled with fresh mortar for installation below the paver covering. Single-grain mortar is most suitable here. The rings should be filled until the mortar protrudes about 5 mm above the rim, so that the pavers can be tapped into the correct height. The 25-mm high plastic rings can be stacked inside each other in a telescopic manner in order to achieve the required height adjustment of the covering, regardless of the slope of the substrate.

The finished covering drains through the open joints of the paver elements into the drainage level beneath. Any water accumulating at this level is then channelled by the slope inclination to the drainage system. Surface drainage systems such as Schlüter-TROBA-PLUS or TROBA-PLUS-G draw away the seepage water and also provide an air cushion that acts as thermal and sound insulation and protects the waterproofing beneath.

| Download | Selection |

|---|---|

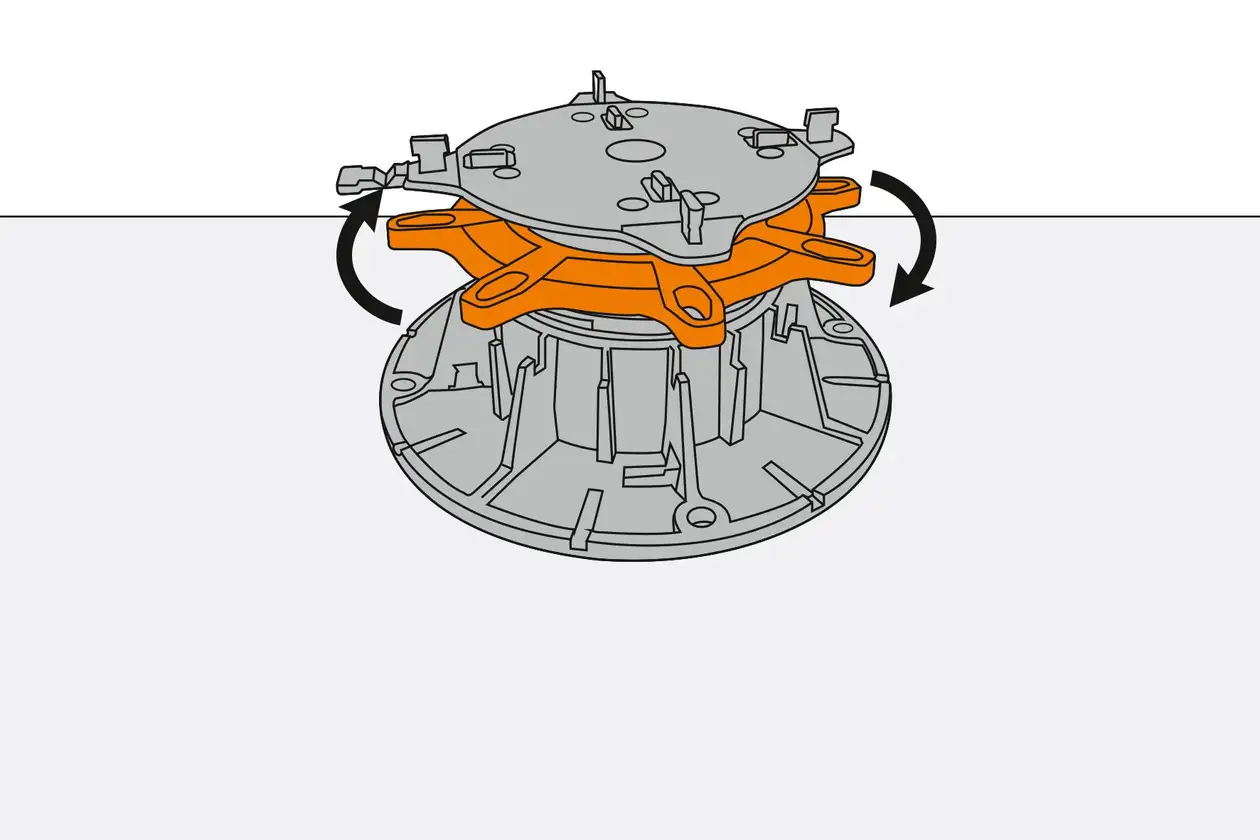

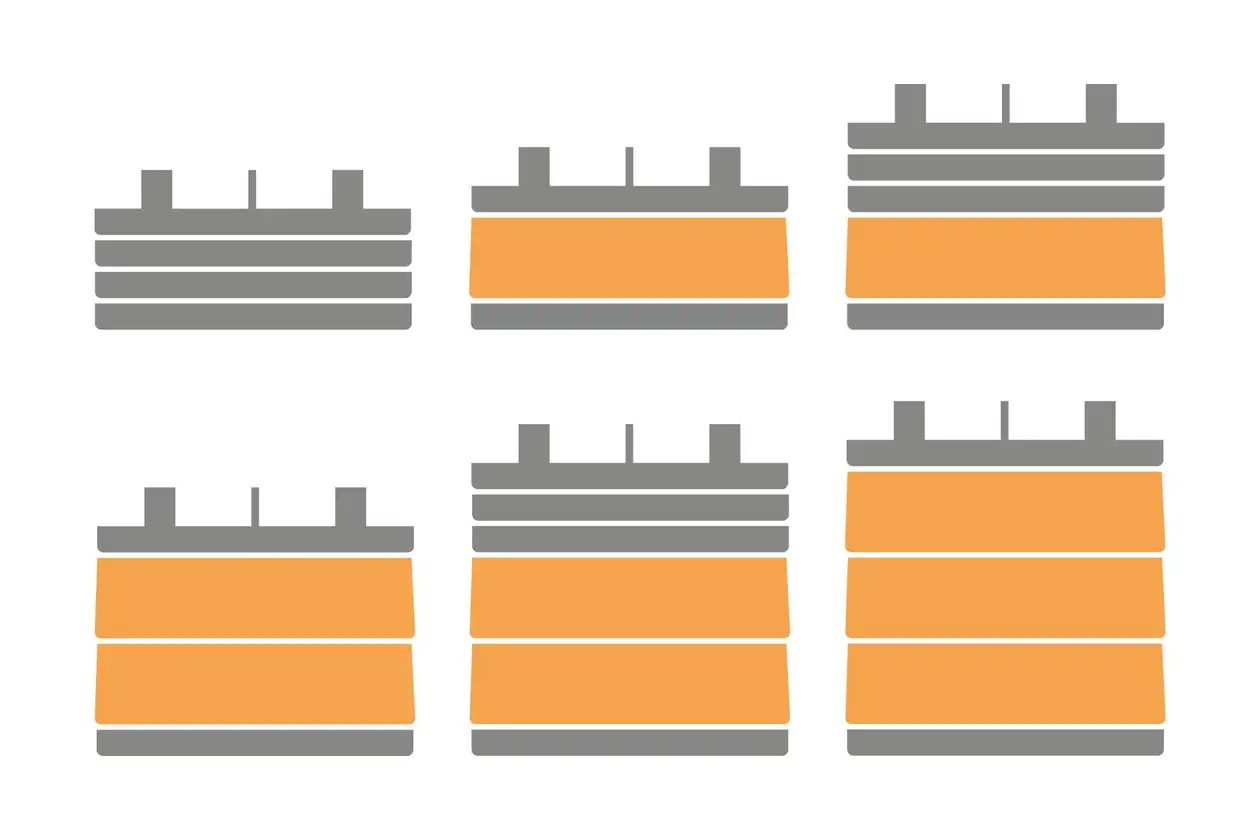

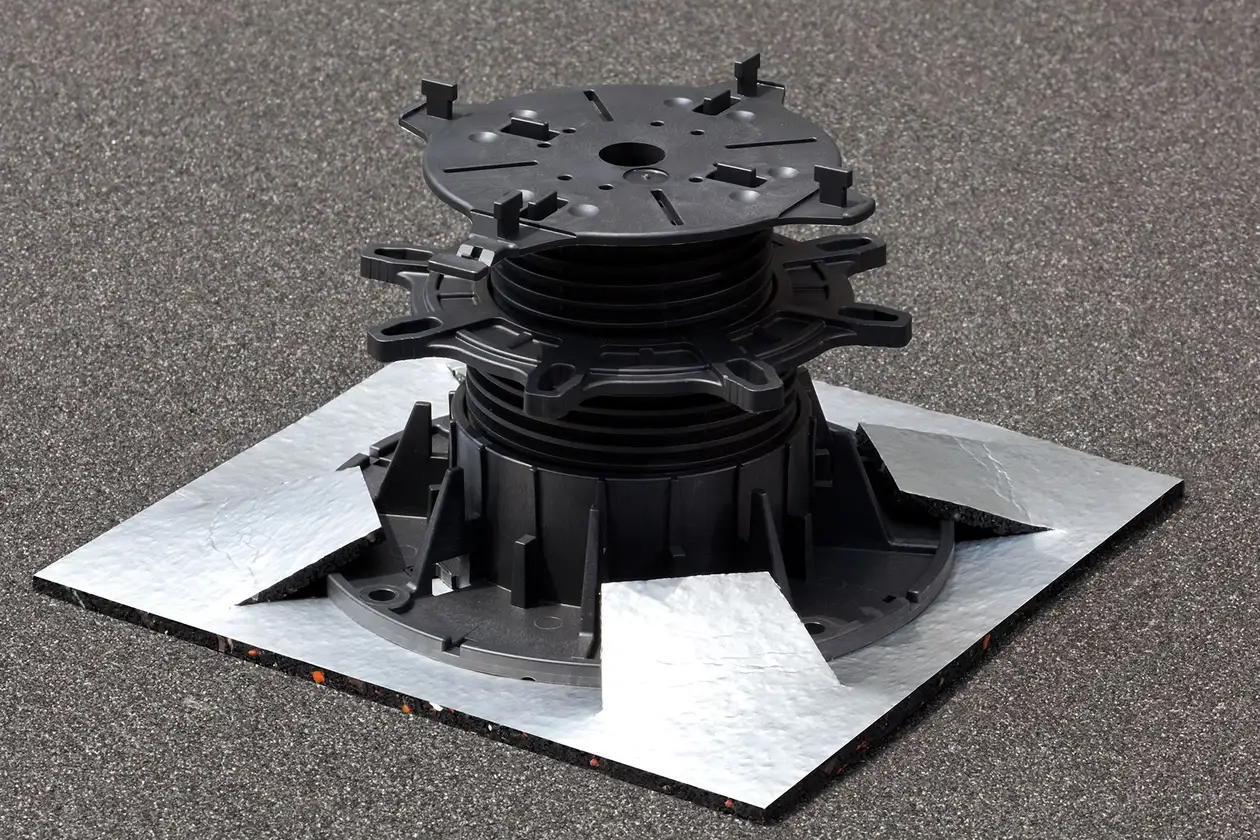

In this type of installation the pavers rest on height-adjustable, stackable paver supports. The construction systems normally comprise a number of combinable elements. Even the pre-assembled components of Schlüter-TROBA-LEVEL can be variably combined and allow construction heights from 3 mm to more than 1 m. Thus almost any incline situation, from 0% to 10%, can be reliably compensated – an unbeatable advantage where a spirit level-optimised substrate is not available. All elements can be stacked or rotated to the required height without special tools.

.The finished covering provides drainage through the open joints onto the waterproofing level of the terrace with its inbuilt slope. This form of installation is also designed to provide a constant ventilation beneath the covering, one benefit of which is to prevent frost damage. Highly sustainable: if a repair is necessary or if the area is remodelled, the pavers can be lifted easily and the system components re-used at any time.

With its seven combinable, height-adjustable or stackable components, Schlüter-TROBA-LEVEL is capable of reliably covering practically all slope and site situations. This facilitates not only handling and planning, but also saves both precious time and storage space.

The unbonded installation with open joints of 3 mm ensures rapid drainage of surface water for the further drainage of the underlying drainage bed. The constant subaeration helps prevent frost damage, and if necessary the components beneath the pavers can be accessed quickly.

The installation of different materials such as ceramic tile and natural stone frequently involves height discrepancies in the substrate and different material thicknesses that must be offset. Thanks to its divisible paver supports and levelling shims, TROBA-LEVEL offers the optimal solution.

TROBA-LEVEL is also ideally suited for use along edges and in corners: the elements can be easily cut to size for neat abutment. Grooves in the materials facilitate accurate sizing. This does not affect the functioning of the system based on snapping together and twisting.

Rapid assembly: all TROBA-LEVEL elements are stacked or are rotated to the required height without special tools. A lock prevents rotatable parts from coming undone and falling out during height adjustment. At the same time, catches prevent unwanted dimension changes occurring due to vibration or weight loading.

Schlüter-TROBA-LEVEL is designed from the outset to be used in a wide variety of combinations – which simplifies your planning and ensures maximum flexibility during installation. The system allows you to respond with ease to unfamiliar or altered conditions at the site without the need for large storage capacity.

Whether you wish to level out, reduce or install on a slope, the flexible TROBA-LEVEL combination options offer solutions for all slope situations up to 10%. TROBA-LEVEL relegates 'wobbling' due to sloping or uneven terrain or irregularities in the pavers to the past, since every single corner can be individually adjusted with millimetre precision.

All components are made from a special plastic that acts to deaden sound and is resistant to wind and weather and also to horizontal creep and weight loading. Moreover, the load distribution disks and protection mats prevent damage to the substrate. If the area is later remodelled, these long-life products can easily be removed and used again.