Responsible consumption and production

Schlüter-Systems combines proven production processes with careful use of resources – and we are constantly improving both.

Environmentally conscious processes. At every level.

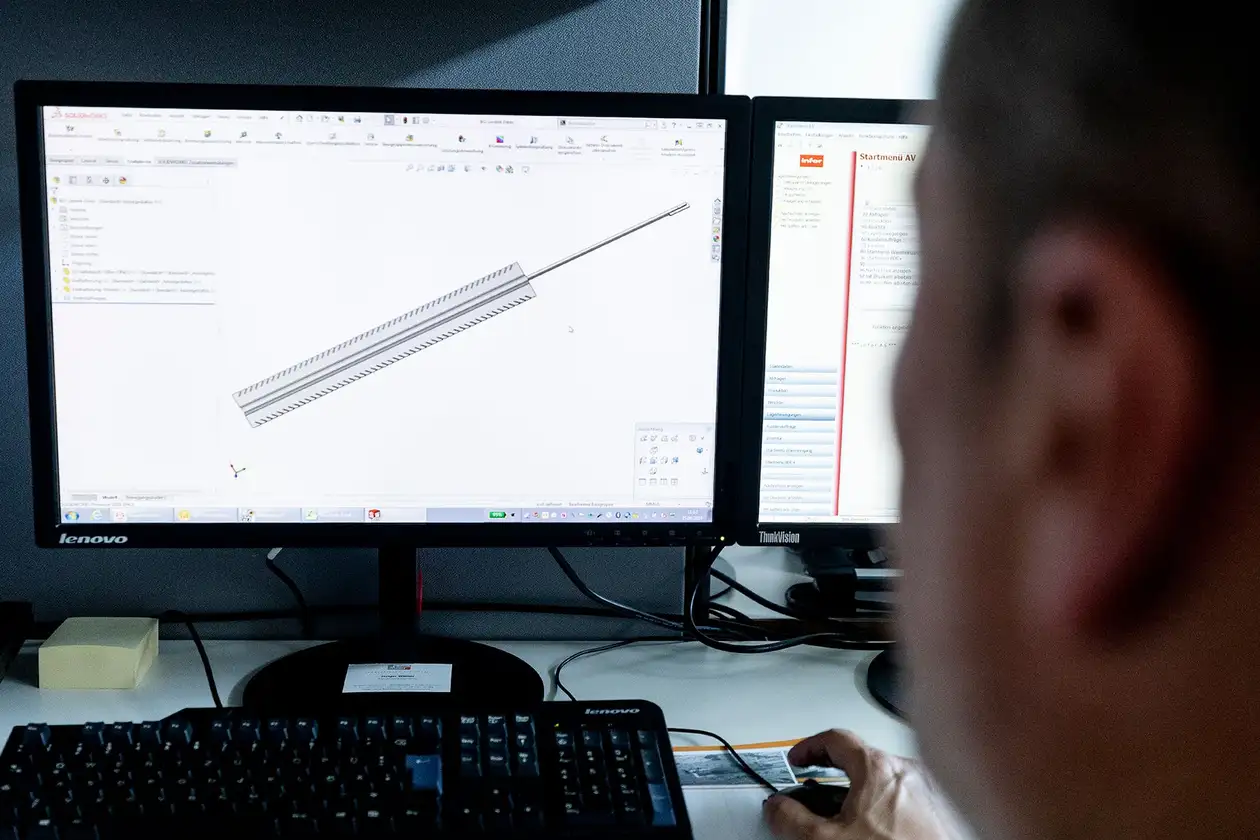

At Schlüter-Systems, we do not just regard production as a technical process, but as the interaction of many factors. Because production methods not only affect the quality of our products, but also the environment and resources. That is why we regularly optimise our processes, systematically integrate new technologies and continuously develop our production processes.

Six areas of expertise. 12,000 solutions.

The Schlüter-Systems product range includes around 12,000 items. The wide range of products is divided into areas of expertise so that architects, planners, craftsmen and homeowners can quickly find the right solution. Each one stands for concentrated know-how and real-world system solutions. Whether profiles, waterproofing, uncoupling, covering assemblies or decorative surfaces – technology, function and design are optimally coordinated here.

Tiles and natural stone pavers. Timeless beauty. Strongly protected.

As the German Agency for Renewable Resources shows in its brochure "Natural flooring made from renewable resources" that is sponsored by the Federal Ministry of Food, Agriculture and Consumer Protection, tiles and natural stone pavers are among the most durable floor coverings of all. 30 to 60 years (in the case of natural stone, this can even be up to 80 years) are not uncommon when installed professionally.

The right edge protection is also crucial for this resilience, especially on external corners, steps or external wall edgings. Edge protection profiles effectively prevent flaking and cracks, protect against mechanical impacts and ensure permanently clean edgings. One classic product that has met this requirement for decades is the Schlüter-SCHIENE – and it has done so in millions of cases: around 50 million linear metres leave the factory in Iserlohn every year.

Constantly improving. With sophisticated technologies.

We are constantly developing our production processes – with the aim of conserving resources and assuring stable processes. Innovation accompanies every step from product development up to production. This allows us to make tangible improvements that advance not just ourselves, but also our partners.

Selected examples of production optimisation:

Chrome-free coating. For better protection and reduced environmental burden.

The colour-coating process of our profiles uses a state-of-the-art coating technology – free of chrome and harmful solvents. The aim is to reduce the environmental burden to a minimum. In 2017, the pretreatment chemicals were changed in accordance with the REACH Regulation (REACH: European Chemical Regulation for the Registration, Evaluation, Authorisation and Restriction of Chemicals): Instead of chrome, a titanium polymer compound is used for reliable corrosion protection.

An added benefit: Excess powder is directly recovered and reused. This saves material, conserves resources and reinforces the demand for efficient, cutting-edge production.

A new approach to water treatment. With smart technology.

An innovative filter system enables an especially economical use of water in the pre-treatment process. To maintain the consistently high quality of the process baths, the bath is regularly refreshed – discharged in a controlled manner, collected in a storage container and temporarily stored.

A specially developed evaporation system then takes over the resource-conserving treatment process: the liquid evaporates in the boiling chamber with the aid of heat and the resulting condensate is collected and returned to the cycle. The remaining concentrate is properly disposed of. The result: An optimised process, reduced water consumption and a consistent step towards sustainable utilisation of resources.

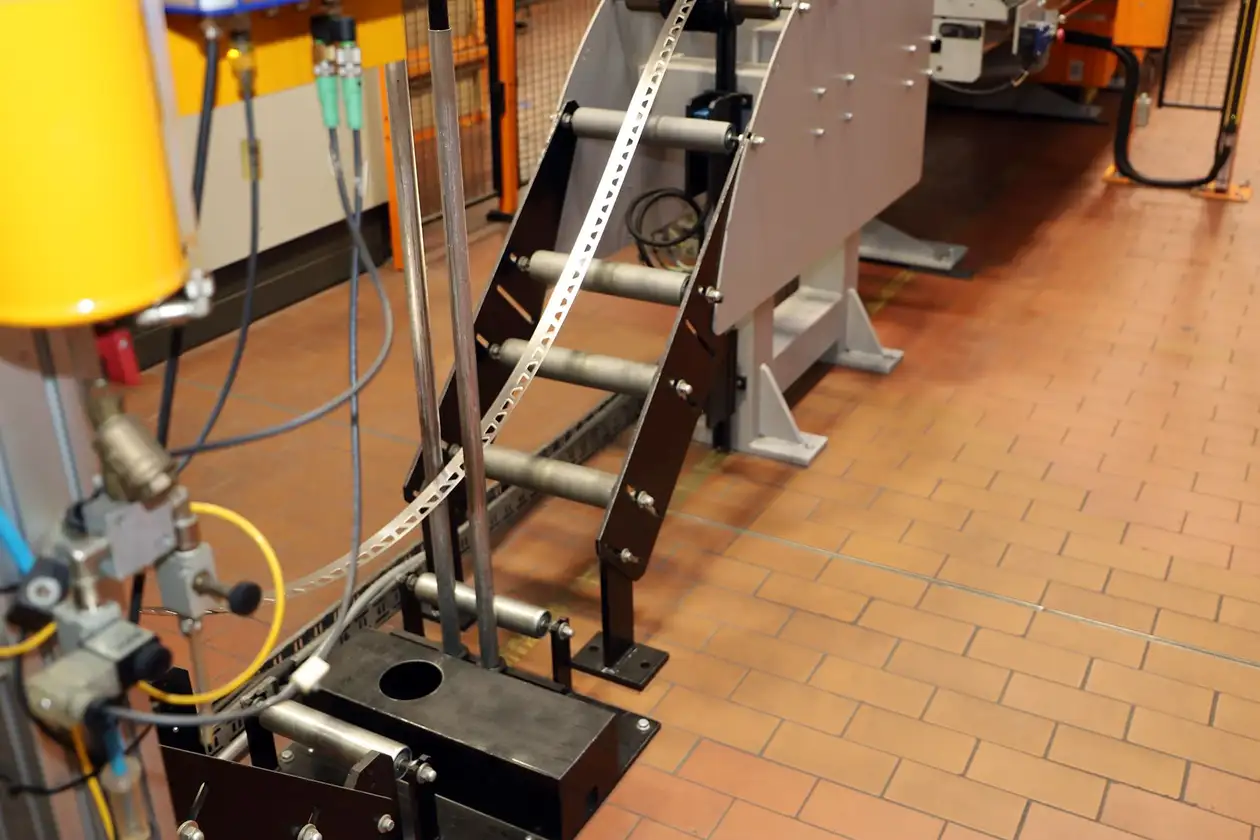

Intelligent loop control. For maximum process reliability.

Intelligent loop control ensures precisely coordinated interaction between the profiling system and the press. The coupler is only activated when it is actually necessary – unnecessary switching processes are omitted.

This ensures continuous, stable press operation without unplanned interruptions. Overloads are reliably prevented, the entire operating process runs smoothly. This reduces wear, reduces maintenance costs and increases the service life of the machine. An efficient solution for consistently reliable production processes.

Resource-conserving packaging: a new solution for rolled strips.

Previously, rolled strips were wrapped in film that had to be discarded after processing – this caused unnecessary waste and additional costs. Today, reusable plastic caps are used. They protect the rolled strips just as dependably, but can be collected and returned to the vendor after use.

This saves material, reduces plastic waste and simplifies the entire packaging process. Quality and transport safety remain, of course, at the usual high level.

Quality starts with precision. And ends convincingly.

Those who, like Schlüter-Systems, want to deliver consistent quality require more than just good materials and modern technology – they need a dependable system. That is why quality assurance is an integral part of every process at our company.

For us, real quality is evident not just in the finished product, but in each and every individual step leading up to it, from the initial material testing to the final touches. It is crucial for smooth processes, satisfied customers and long-term success.

Test stations in Incoming Goods

To deliver quality, you must receive quality. Our test stations in the incoming goods department are the first crucial step in the quality assurance process – because anything overlooked here can become very costly later on. That is why we test consistently and systematically.

Checking with a keen eye for detail

All deliveries are subjected to rigorous testing: dimensional accuracy, surface finish, strength or level of gloss – depending on the product, the focus is on clearly defined test parameters. Regardless of whether it is a cross cutting test and colour measuring device for coatings or a light measuring cabin for LIPROTEC: our equipment is designed for precision.

Focus on important documents

Supplier specifications that stipulate what a product must fulfil down to the smallest detail, quality agreements regarding standards for delivered products and accepted error tolerances, delivery notes, packing lists – not only do we check the goods themselves, but also the accompanying documents. Only when everything is in order can we proceed.

From the start right up to shipping: everything flows smoothly.

From the arrival of raw materials and other materials, through the production process, to the picking and delivery of our products and system solutions: we think through every stage of the process. Digitally controlled processes, energy-efficient technology and carefully planned procedures ensure that everything runs smoothly – while conserving resources as much as possible.

A new approach to logistics. Compact, clever, centralised.

Thanks to the construction of the new logistics centre at its headquarters in Iserlohn, Schlüter-Systems is now able to consolidate all its logistics processes under one roof. On an area of around 21,000 square metres, the building has storage space for 11,500 pallets, more than 10,000 cassettes and around 35,000 boxes – and consolidates all goods flows in one central location.

What was previously spread over multiple buildings is now digitally controlled, efficiently networked and fully automated: three high-bay warehouses, a separate transport track with ten vehicles and ten driverless transport vehicles ensure smooth processes – from brochures to complete floor heating systems. Cutting-edge technology makes logistics paperless and fit for the future.

Stop with service and system: Schlüter Truck Stop.

The Schlüter Truck Stop is fully adapted to modern logistics processes: the check-in desk is manned around the clock and an emergency call centre is always on duty. Ample parking spaces offer plenty of room – even for large lorries – and modern washroom facilities with showers and toilets provide additional convenience. The area around the station also benefits from the new arrangement, because the centralised processing reduces through traffic in the neighbouring residential area.

And another plus point: the Truck Stop has created more parking spaces for Schlüter-Systems employees. The solar canopy provides environmentally friendly electricity that is used to power the electric charging stations installed here.