Schlüter-DESIGNBASE-QD is available in the following materials:

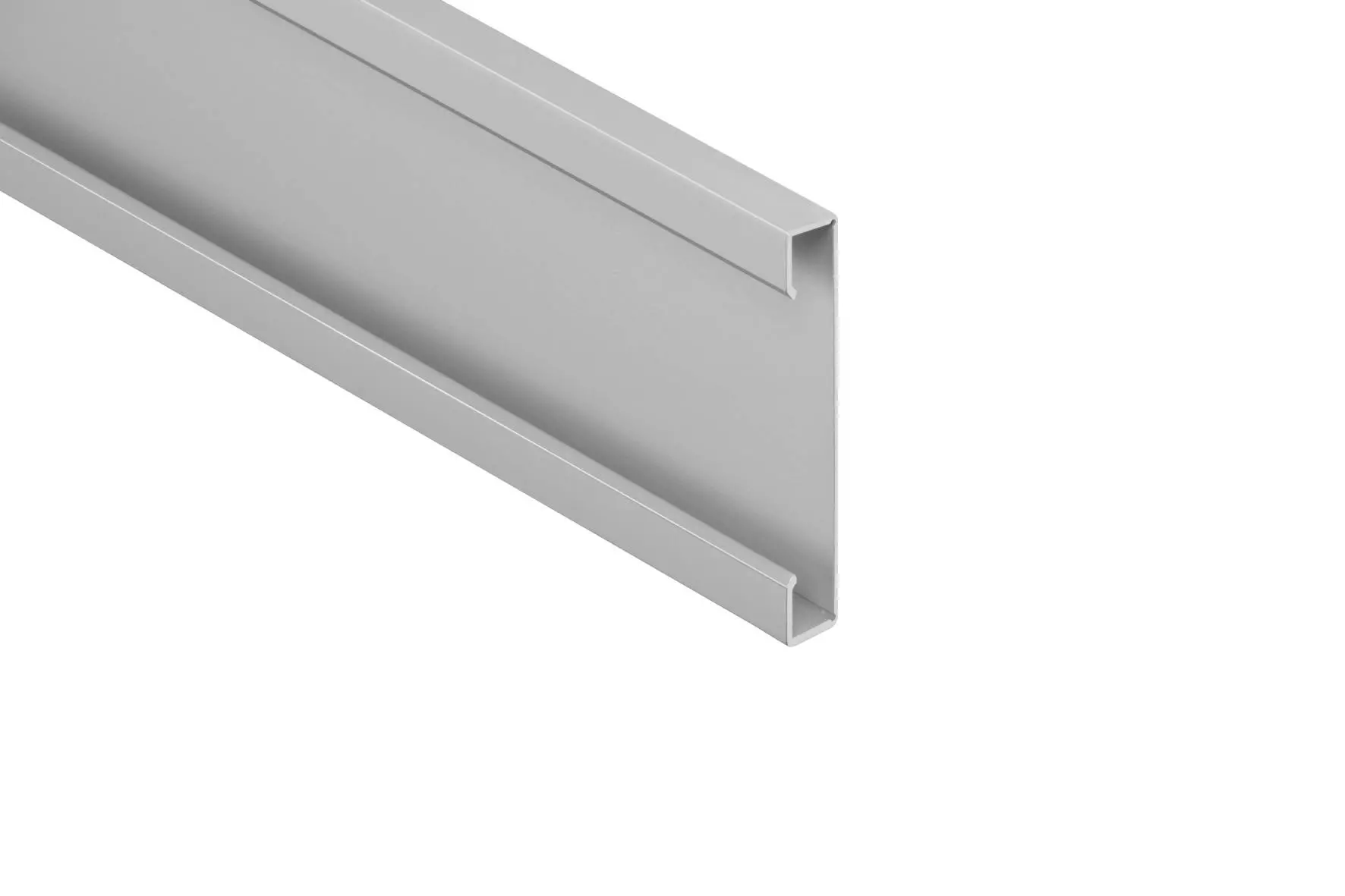

Profile:

- AE = anodised aluminium

- AEEB = brushed stainless steel effect anodised aluminium

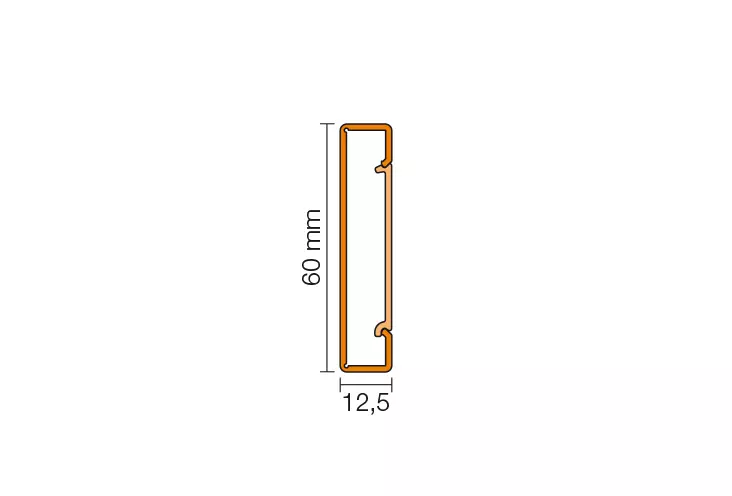

Diffuser lens:

- PMMA = Polymethyl methacrylate

Material properties and areas of application

In applications exposed to chemical or mechanical stresses, the profile’s suitability must be verified.

The information provided below is intended as a general guideline.

Schlüter-DESIGNBASE-CD-AE /-AEEB (anodised aluminium): The aluminium features an anodised finish that retains a uniform appearance during normal use.

Damaged anodised surfaces can be restored with paint.

Surface areas must be protected against abrasion or scratching. Aluminium is sensitive to alkaline media. Cementitious materials, in conjunction with moisture, become alkaline, which may result in corrosion depending on the concentration and length of exposure (aluminium hydroxide formation). For this reason, remove adhesive or grouting material immediately from all visible areas and do not cover freshly installed coverings with foil.

LIPROTEC diffuser lenses are made of a slightly structured, translucent thermoplastic PMMA (polymethyl methacrylate).

Surface areas must be protected against abrasion or scratching. Remove all adhesive and grouting material immediately.

Alcohol (e.g. rubbing alcohol) as well as detergents with a surfactant content over 5% can cause damage to the diffuser lens.

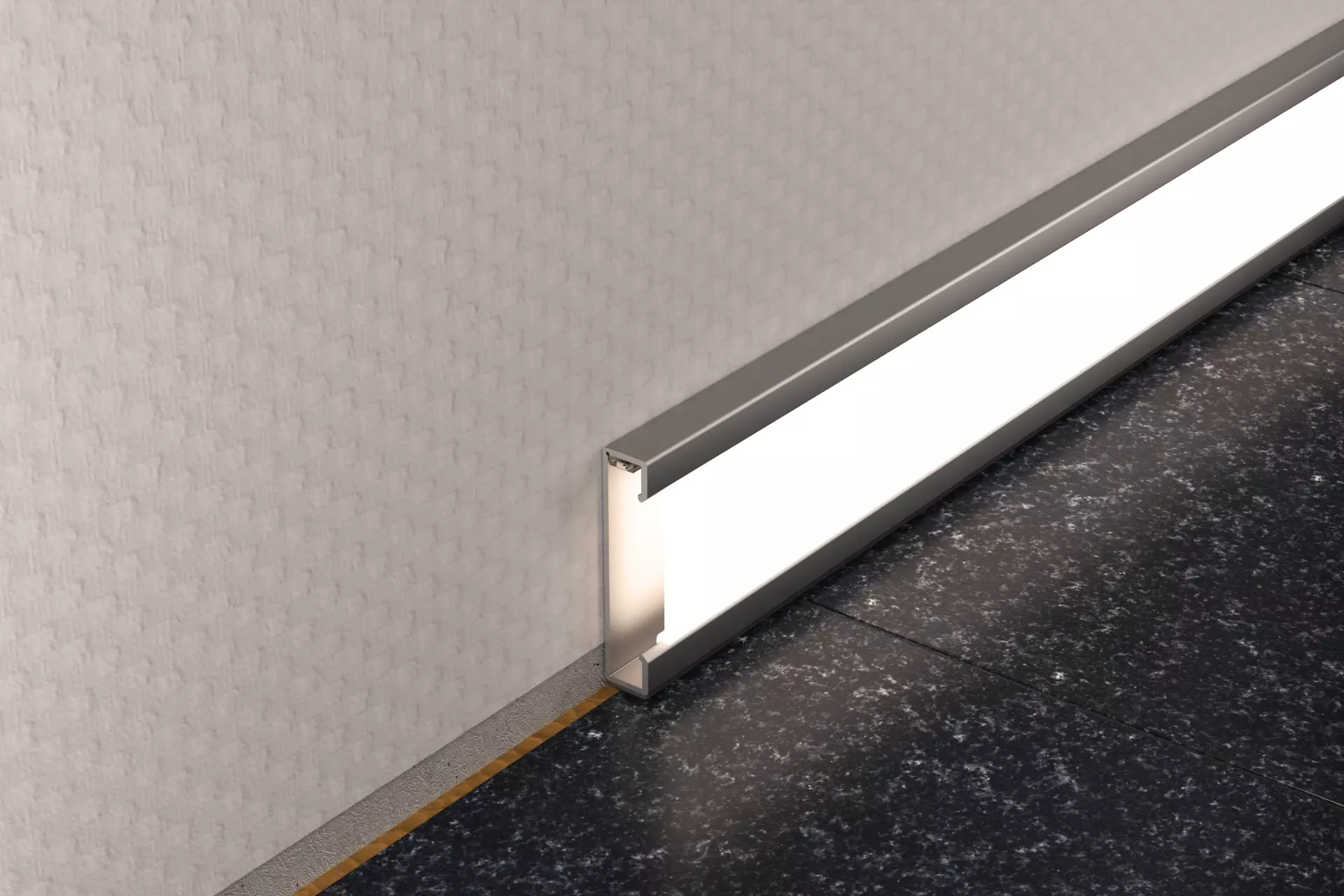

Note: The profiles with their decorative and diffuser lens covers must be positioned so that no water can collect inside.

Due to minor heat development of the LED strips used in the profile, the expansion of the profile and the utilised diffuser lens may differ.