- Always check the substrates on which Schlüter-REFLEECE is to be installed to make sure they are level, load-bearing, clean and compatible with the materials to be used. Remove all surface components that may weaken the bond.

- Thoroughly vacuum the substrate prior to installation to remove all dust.

- Roll out the REFLEECE sheets and cut them to the necessary size. Then align the mats and press them evenly on the substrate, using a float or roller.

- Attach the self-adhesive Schlüter-DITRA-SOUND-KB sealing tape over all abutting joints and floor-wall transitions. To prevent any damage to the installed REFLEECE material or detachment from the substrate, protect the area from mechanical stresses, e.g. by setting out running boards (particularly in areas used for material transport).

- Tiles can be installed immediately after adhering REFLEECE, using the thin-bed method. Use the smooth side of the trowel to apply thin-bed tile adhesive to the fleece surface and then create grooves with the notched side.

- Fully embed the tiles in the adhesive. The notch size of the trowel must match the tile size. Observe the curing time of the adhesive.

- Continue the movement joints from the substrate in the tile covering as specified by the applicable regulations. Otherwise, divide large tile coverings installed above the REFLEECE layer into sections with movement joints according to the applicable regulations. We recommend using the profiles of the Schlüter-DILEX family.

Note:

The cementitious adhesive and the covering material used in conjunction with Schlüter-REFLEECE must be suitable for the respective floor area and meet the corresponding requirements.

Removal

- Separate the tile covering at the joints with an appropriate tool. The insertion depth of the tool must be chosen to avoid any damage to the permanent substrate. Depending on the size of the tiles, it may be advisable to divide the tile material into smaller pieces.

- Now use a vacuum lifting tool to pull up the separated tile pieces, together with the tile adhesive and REFLEECE, for disposal.

- Thoroughly vacuum the substrate and clean it with clear water or a suitable detergent.

Note:

Wooden or natural stone substrates may need additional treatment steps as specified by the manufacturer after cleaning the surface.

Substrates

Always check the substrates on which REFLEECE is to be installed to make sure they are level, load-bearing, clean and compatible with the materials to be used. Remove all surface components that may weaken the bond.

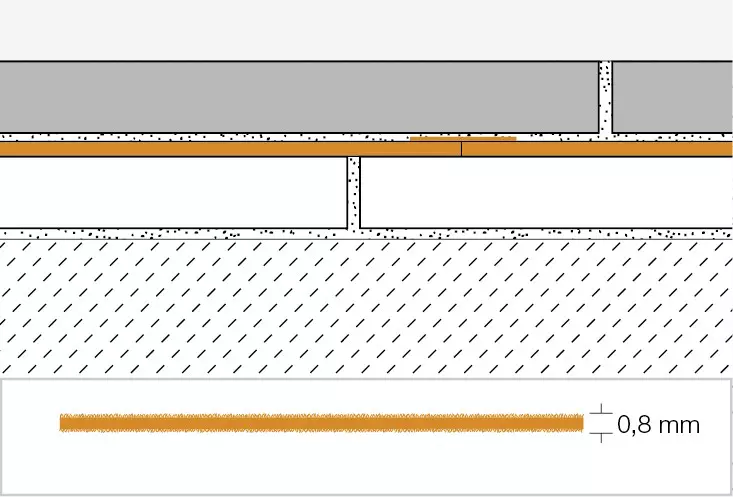

REFLEECE is suitable for installation over heated floor assemblies. In this case, the applicable regulations for conventional heated screeds in conjunction with tile coverings must be observed.

The surfaces of the substrates to be covered must be load-bearing and suitable for attaching the self-adhesive bonding layer of the fleece. REFLEECE can only be installed over permanently adhered substrate assemblies. Floating assemblies cannot be covered with a rigid top covering.

The compatibility of the bonding layer with the substrate must be verified in advance. REFLEECE may only be installed on substrates that are free of solvents and plasticisers.

Any residue of the bonding layer remaining on the substrate after peeling off the removable fleece can easily be washed off with clear, lukewarm water. REFLEECE is fully recyclable.

Notes on movement joints

Separate the removable REFLEECE layer over existing movement joints. Continue the movement joints in the tile covering as specified by the applicable standards. Otherwise, divide large coverings installed above the REFLEECE layer into sections, using movement joints according to the applicable standards.

We recommend using the profiles of the Schlüter-DILEX family. Arrange profiles such as Schlüter-DILEX-BT or Schlüter-DILEX-KSBT over existing expansion joints depending on the anticipated structural movements.

It is important to prevent stress build-up at the edges of the covering, for instance at upright structural components or at floor-wall transitions. Perimeter movement joints and connection joints must be constructed according to the applicable technical regulations and have sufficient dimensions to prevent stress build-up. We recommend using the various profile types of the DILEX family.