The profile is available in the following materials:

- E = stainless steel

- V2A, material no. 1.4301 = AISI 304

- V4A material no. 1.4404 = AISI 316L

- EB = brushed stainless steel

- EP = polished stainless steel

Material properties and areas of application

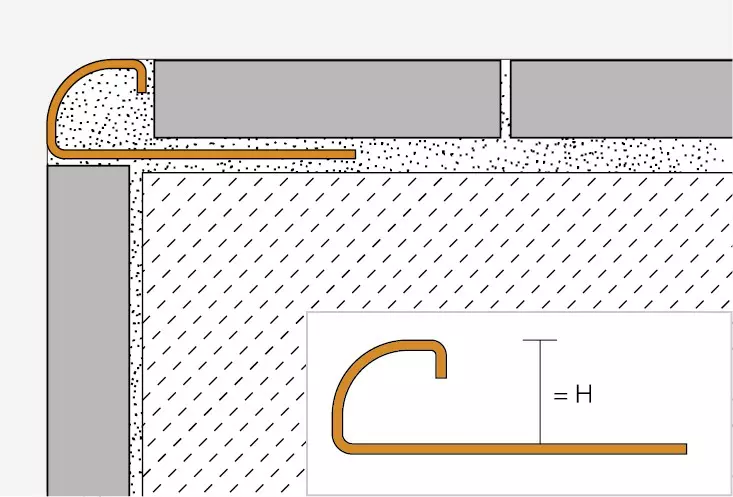

Schlüter-RONDEC is available in a wide variety of materials and finishes.

In applications exposed to chemical or mechanical stresses, the profile’s suitability must be verified. The information provided below is intended as a general guideline.

Schlüter-RONDEC-E (stainless steel), made of material 1.4301 (V2A) or 1.4404 (V4A), is suitable for applications requiring resistance against chemical exposure and high mechanical stresses. Application areas include industrial food production facilities such as breweries, dairies, industrial kitchens, and hospitals as well as residential spaces. Depending on the anticipated chemical stresses, customers can choose between the alloy materials 1.4301 (V2A) or 1.4404 (V4A). The use of V4A is recommended if consistent exposure is expected, for example in the case of swimming pools (fresh water).

Even stainless steel of quality 1.4404 is not resistant to all chemical stresses such as hydrochloric and hydrofluoric acid or certain chloride and brine concentrations.

In certain cases, this also applies to salt water pools. The anticipated chemical stresses should therefore be verified in advance.

Note: Due to different manufacturing processes, slight colour discrepancies between the profiles and the corners may occur.