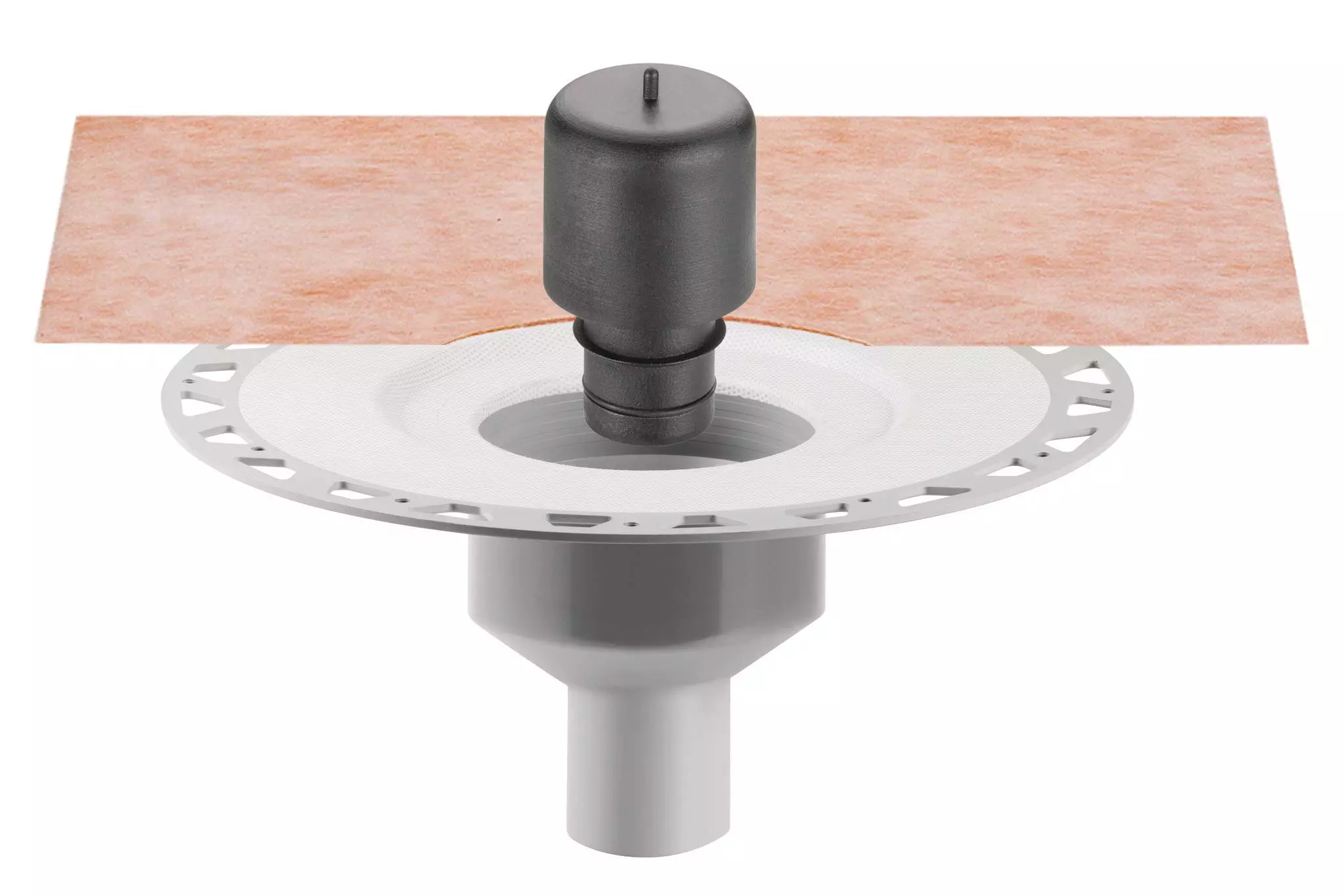

Depending on the type, the drain bodies are made of high-impact resistant polypropylene (PP) or acrylonitrile butadiene styrene (ABS). The bonding flange is made of acrylonitrile butadiene styrene (ABS) and features an adhesive flange with a fleece-coated surface.

The Schlüter-KERDI collar is a crack-bridging waterproofing membrane of soft polyethylene (PE) with a special fleece fabric laminated on both sides for effective anchoring in the tile adhesive. It ensures the reliable connection of the bonding flange to the bonded waterproofing assembly in the floor area.

In conjunction with the waterproofing systems Schlüter-KERDI, Schlüter-DITRA, Schlüter-DITRA-HEAT or Schlüter-KERDI-BOARD as well as Schlüter-KERDI-SHOWER and the matching system adhesives Schlüter-KERDI-COLL-L or Schlüter-KERDI-FIX, installers can create certified bonded waterproofing assemblies with connecting drainage.

Schlüter-KERDI-DRAIN is a system component that complies with the German waterproofing standard DIN 18534. Together with the above-listed Schlüter-Systems it has general technical approval (abP) in Germany.

Please refer to the respective product data sheets for information about the moisture exposure classes according to abP.

Schlüter-KERDI-DRAIN is a system component with European Technical Assessment (ETA) according to ETAG 022 (watertight covering kits). The above-listed Schlüter products tested together with KERDI-DRAIN bear the CE mark.

The stainless steel grate is made of V2A (material no. 1.4301 = AISI 304) and can also be supplied in stainless steel V4A (material no. 1.4404 = AISI 316L).

Material properties and areas of application

The drain body, bonding flanges and covers are classified as K3 according to DIN EN 1253, Gullies for buildings. This class refers to areas without vehicle traffic, e.g. wetrooms in apartments, nursing homes, hotels, schools, and public washroom and shower facilities, on terraces, patios and balconies.

Drains to be installed in areas exposed to freezing temperatures may not include an odour trap. Any required odour trap must be protected from freezing, e.g. within building structures.

The horizontal drain body of the floor drain set KD BH 50 GV has both an inlet and a drain. The inlet comes with a pre-adhered cap. It can be connected, for instance, to a sink to keep the odour trap filled with water.

Grates made of stainless steel 1.4301 (V2A) or 1.4404 (V4A) are particularly well suited for applications that, in addition to heavy mechanical stresses, require resistance to chemicals such acidic or alkaline media, detergents and de-icing salt. Depending on the anticipated stresses, customers can choose between the alloy materials 1.4301 or 1.4404 for the grates. The use of V4A is recommended if consistent exposure is expected, for example in the case of swimming pools (fresh water). Even stainless steel of quality 1.4404 is not resistant to all chemical stresses such as hydrochloric and hydrofluoric acid or certain chloride and brine concentrations. In certain cases, this also applies to seawater pools. The suitability of a proposed floor drain system must be verified based on the anticipated chemical, mechanical and/or other stresses. Aggressive cleaning products should not be used.