- The substrate must be free of anything that could inhibit adhesion, level and load-bearing. Any necessary levelling work must be completed before installing DITRA-PS.

- The substrate must be dust-free before installation and must therefore be thoroughly vacuumed.

Note: Although it is not mandatory to apply a primer, a standard primer without coarse components such as quartz sand may be used if the condition of the substrate necessitates it.

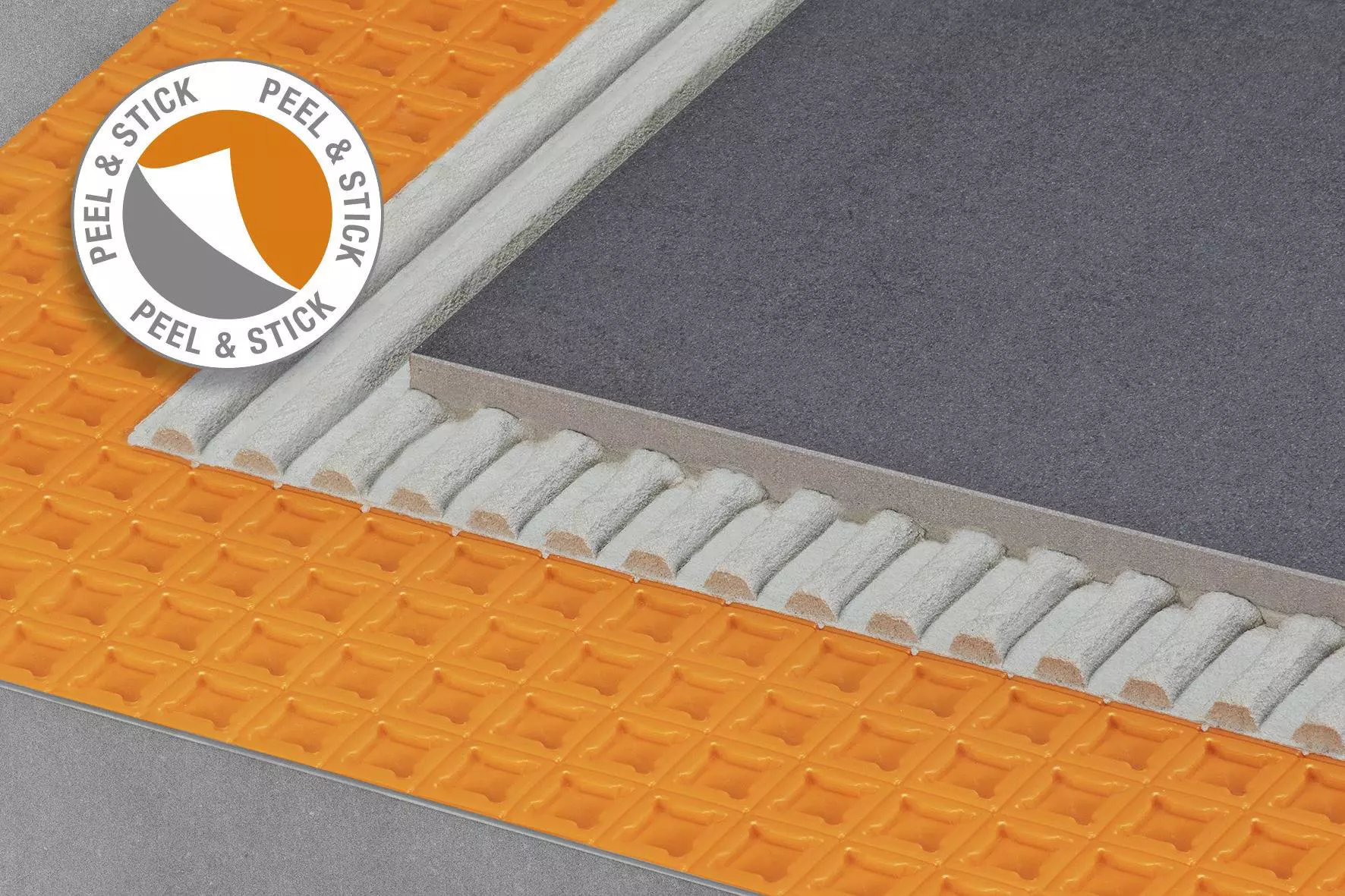

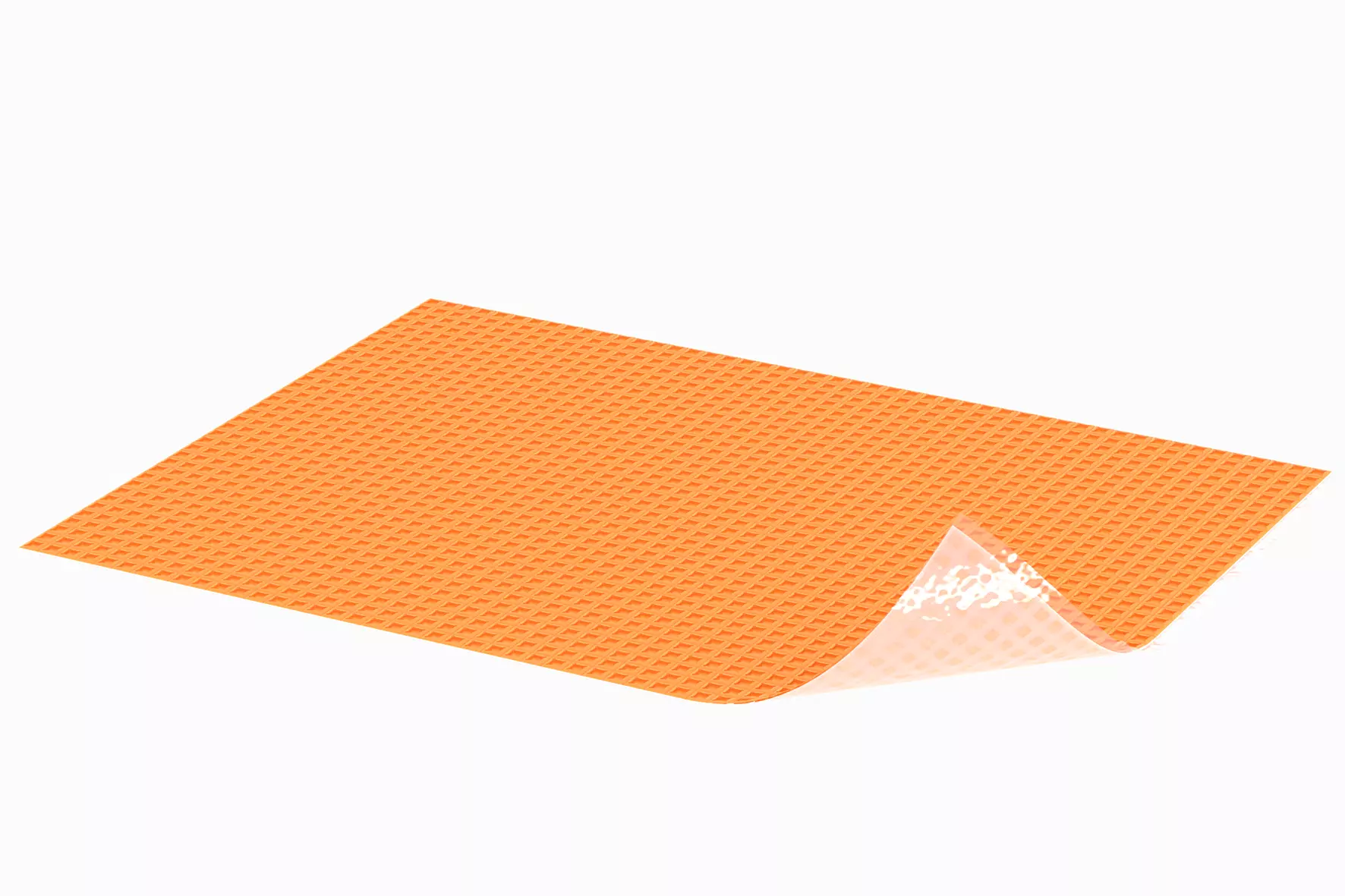

- Cut the uncoupling mat DITRA-PS to size and lay it out on the floor. Now remove the release film from the fleece on the underside and press the mat evenly on the substrate, using a float or roller. It is helpful to align the DITRA-PS accurately as soon as it is laid and to lay it under a slight tension.

- To prevent damage to the laid DITRA-PS or its becoming detached from the substrate, we recommend that you protect the area from mechanical stresses, e.g. by laying out running boards (particularly in areas used for transport of materials).

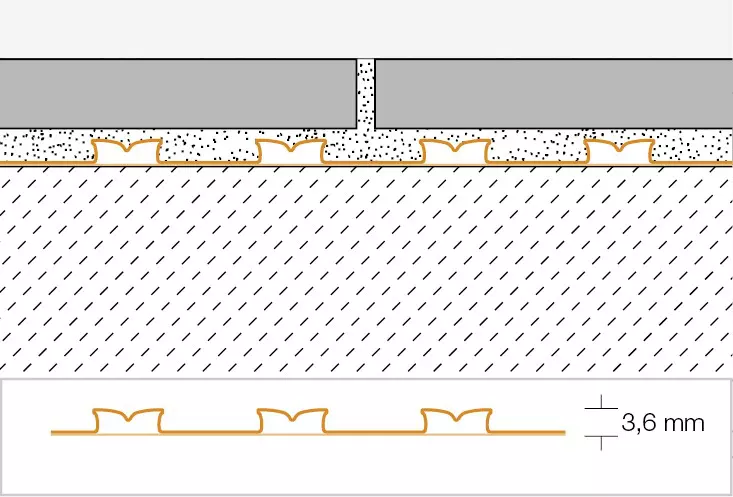

- Immediately after fitting the DITRA-PS, tiles can be installed using the thin-bed method, using a thin-bed mortar appropriate to the requirements of the covering. The notch size of the trowel must suit the tile format. Observe the curing time of the thin-bed mortar. The tiles should mostly be fully embedded in the mortar. Full contact according to the applicable professional regulations is especially relevant for coverings exposed to high mechanical stresses.

Note: The square indentations can be filled using the smooth side of the notched trowel (mortar requirement approx. 2.0 kg/m²) and the thin-bed mortar can then directly be grooved with the (correctly sized) notch, in a single work step. Depending on the tile size or the site conditions, it may alternatively be more effective to first fill the indentation with the tile adhesive used for the installation. Tile installation can begin once the trowelled surface is firm enough to walk on. Note that the substrate must be free of dust prior to installation. If necessary, vacuum the substrate prior to installation or apply a primer in case of doubt.

Any potential material incompatibilities should be checked beforehand. If using covering materials with a side length exceeding 30 cm, we recommend a fast-setting tile adhesive with crystalline water binding to facilitate the rapid strength development and drying of the mortar.

- Follow the instructions in the data sheet and the other technical regulations when installing movement joints for perimeter, edge or connection joints.

Waterproofing with Schlüter-DITRA-PS

Unless a certified bonded waterproofing assembly is required, DITRA-PS can serve as a waterproofing layer, provided the abutting membrane seams and the connections to installed components and upright building structures are carefully sealed.

If national technical approval (abP) or European approval (ETA = European Technical Assessment) is needed, choose the DITRA variants for installation with thin-bed mortars that have the corresponding certification.

DITRA-PS protects the substrate from damage caused by permeating moisture and aggressive substances. For sealing joints, trowel the sealing adhesive Schlüter-KERDI-COLL-L over the abutting joints and embed the sealing band Schlüter-KERDI-KEBA in a minimum width of 12.5 cm over the joints.

To waterproof floor-wall transitions, adhere KERDI-KEBA over DITRA-PS on the floor and directly on the substrate in wall areas in the corresponding width. The sealing tape must have an overlap of at least 5 cm. KERDI-KEBA can also be used to create functional connections to fixed structural components such as door and window frames made of metal, wood or plastic. The first step is to apply Schlüter-KERDI-FIX to the adhesive surfaces of the structural elements. The remaining width is then fully adhered to DITRA-PS with KERDI-COLL-L.

The suitability of KERDI-FIX for the materials of the structural components must be verified in advance. Separate DITRA-PS at existing movement joints or structural movement joints and seal the abutting joints with Schlüter-KERDI-FLEX.

KERDI-FLEX should also be used for flexible edge finishes. KERDI-KEBA can also be used here as an alternative, by forming an appropriate loop.

Substrates for Schlüter-DITRA-PS

The substrates on which DITRA-PS is to be installed must be thoroughly checked for suitability, e.g. that they are level, load-bearing, clean and compatible with the materials used. Remove any surface components that could weaken the bond. Any levelling, height adjustment or slope compensation must be carried out before DITRA-PS is laid.

Concrete

Concrete is prone to long-term structural deformation due to shrinkage. In addition, deflection in concrete and pre-stressed concrete can cause tensions to occur.

Since DITRA-PS absorbs the resulting stresses between the concrete and the tile covering on the floor, tiles can be immediately installed as soon as the concrete is ready to bear weight.

Cement screeds

Cement screeds must have cured for at least 28 days prior to tile installation in accordance with the applicable regulations and have a moisture content below 2 CM %. Floating and heated screeds have a particular tendency to buckle and crack even later, e.g. due to mechanical stresses and temperature fluctuations. With DITRA-PS, tiles can be installed on fresh cement screeds as soon as their surface is sufficiently dry (typically this takes approx. 3-5 days for well-ventilated standard cement screeds). DITRA-PS neutralises cracks and screed deformations that occur later and prevents them from affecting the tile covering.

Gypsum based screeds

Under the applicable regulations, calcium sulphate (anhydrite) screeds may have a maximum residual moisture level of 0.5 CM% at the time of tile laying. In contrast, tile installation is permissible from a residual moisture level of 2 CM % with DITRA-PS. If necessary, the screed surface should be treated (grinding, priming) as specified by the technical regulations and manufacturer instructions. DITRA-PS can then be affixed to the pre-treated screed surface. DITRA-PS protects the screed surface against permeating moisture. Because gypsum based screeds are susceptible to moisture, screeds must be protected against humidity, e.g. moisture seepage on the underside.

Heated screeds

DITRA-PS can be used on heated screeds, provided that the notes given above (on cement and calcium sulphate) are observed. Covering assemblies created with DITRA-PS are ready for heating only 7 days after completion. Starting from a temperature of 25 degrees C, the supply temperature can be increased by no more than 5 degrees C a day to a maximum of 40 degrees C. The air channels formed by the DITRA-PS mat allow rapid and even heat distribution under the tile covering.

Note: For floor heating systems, we recommend our Schlüter-BEKOTEC-THERM system as a ceramic thermal comfort floor. DITRA-PS is also highly suitable for uncoupling in conjunction with floor heating systems based on thin electric heating mats. In those cases, Schlüter-DITRA-PS can be installed above or below the heating mat. However, a better uncoupling effect is obtained by placing it above the heating mat. Schlüter-DITRA-HEAT/HEAT-PS was developed specifically as an uncoupling mat designed to attach the matching system heating cables for electric floor/wall heating systems. You can find further details in product data sheets 6.4 and 6.5.

Dry screeds

When fitting DITRA-PS, once dry screed elements have been correctly installed according to manufacturer instructions, you can choose the maximum tile format in any size.

Vinyl coverings and coatings

All surfaces must be load bearing and pre-treated or suitable for bonding with the adhesive anchoring fleece on the underside of DITRA-PS. The compatibility of the adhesive with the substrate must be verified in advance. DITRA-PS may only be installed on substrates that are free of solvents, plasticisers and oils.

Chipboard and compressed wood panels

These materials are prone to particularly severe deformation under the influence of moisture (or fluctuations in air humidity). It is therefore recommended to use chipboard and compressed wood panels with special water-repellent treatment to protect against moisture. However, they have to be thick enough to be sufficiently stable in conjunction with a suitable support assembly. They should be secured with screws placed suitably close together. Joints should be of a tongue-and-groove type and must be bonded with adhesive. Edge joints of about 10 mm should be maintained to adjacent structural elements. DITRA-PS neutralises any tensions with the tile covering and also prevents permeating moisture.

Hardwood floors

In principle, ceramic coverings can be installed on sufficiently weight bearing hardwood floors with tongue and groove connections. The wooden substrate should have balanced moisture levels before DITRA-PS can be installed. It has proven beneficial here to lay an additional layer of chipboard or compressed wood panels. Uneven floor surfaces should be levelled with suitable measures beforehand.