BEKOTEC-THERM-ER/WL

Wireless thermostat for heating/cooling living spaces

Our floor heating system Schlüter-BEKOTEC-THERM stands for maximum living comfort and minimal energy consumption!

Cosy, warm feet in winter and a cool room temperature in the hot months: Schlüter-BEKOTEC-THERM is the water-based floor heating system that will enhance your living quality to the next level. Discover our energy-saving complete system!

In comparison to conventional floor heating systems, BEKOTEC-THERM impresses with its thin-layer construction that requires a minimum screed covering of just 8 mm. This saves up to 80 kg of screed mass per square metre – which is why BEKOTEC-THERM is ideal for installation in new construction projects and for retrofitting as part of a renovation or modernisation project.

Up to 28 days sooner into your own home thanks to the design advantages of the BEKOTEC system: The flat design means that not only does less screed have to dry – when using a conventional cement screed in combination with an uncoupling mat, there is also no need for time and energy-consuming heating of the covering. The freshly installed screed can continue to dry while you are laying the tiling – huge advantage for both new construction projects and renovations.

In comparison to conventional heating systems, BEKOTEC-THERM requires only half as high a supply temperature of around 30 °C, because our thin-layer system ensures that the warm heating pipes are closer to your feet. As a result, significantly less screed needs to be heated up before the floor covering can radiate heat. This also means that the floor heating system can react more quickly to changes in the temperature controller. Optional insulation ensures that the heating pipes radiate even more heat upwards and the energy saving potential increases further.

Our innovative control technology enables even greater energy efficiency to be achieved: the temperature controller allows you to conveniently set the required setpoint, the timer unit controls a night-time reduction and the smart actuators, available on request, ensure adaptive hydronic balancing to guarantee an optimum and energy-efficient flow of hot water at all times.

Thin-layer construction, less screed material, lower supply temperature: the BEKOTEC-THERM system is designed in such a way that you get the maximum benefit out of it. A practical scientific test carried out by the Institute for Building Systems Engineering Research and Application (ITG) in Dresden has shown that BEKOTEC-THERM can save up to 9.5 % energy a year compared to conventional floor heating systems. Its design advantages are especially noticeable in combination with renewable energy sources and thermally conductive ceramic or natural stone coverings – that's why we at Schlüter-Systems also proudly speak of it as a ceramic thermal comfort floor.

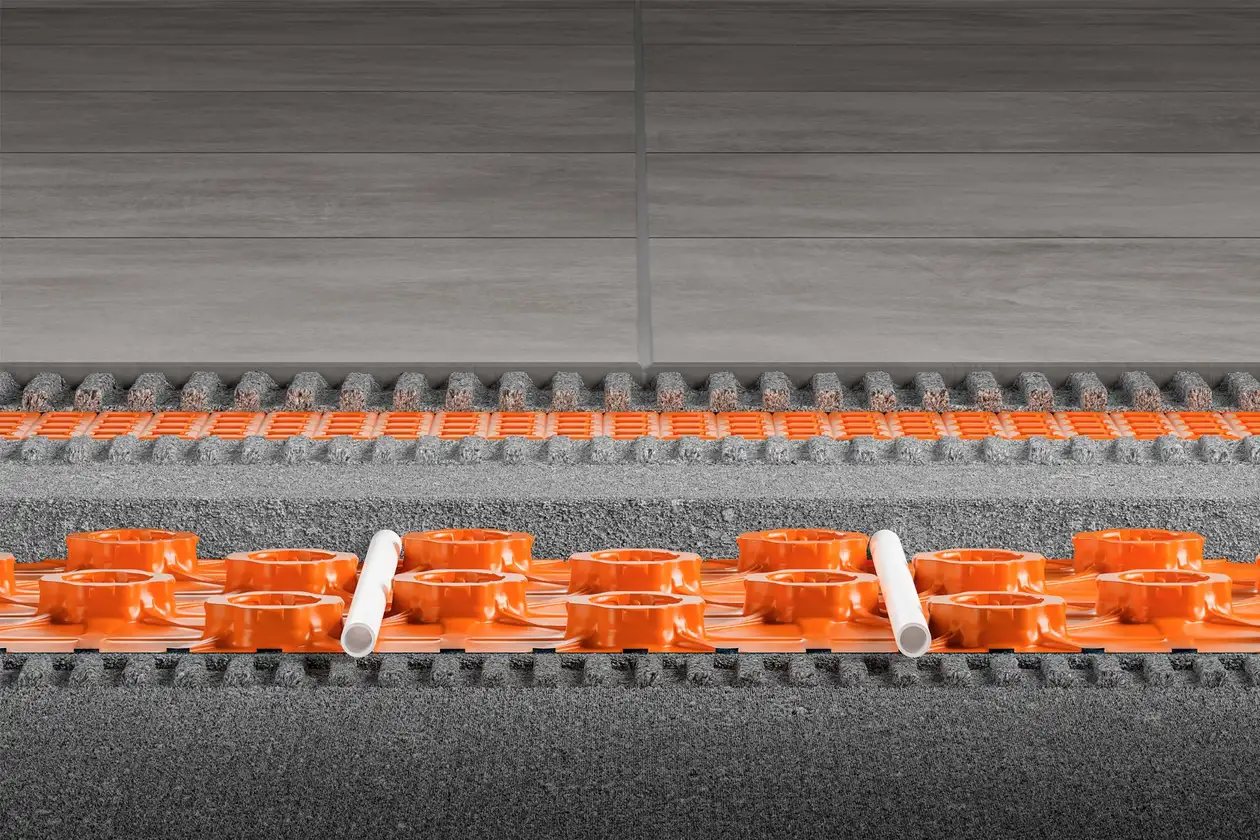

Through our five systems, BEKOTEC-THERM can respond flexibly to your individual requirements – irrespective of whether planned from the outset in a new construction or when modernising an older building. If the space available in existing buildings is limited and the substrate is fixed, this can be solved by choosing a system with a low installation height: Schlüter-BEKOTEC-EN-FK, for example, requires just 20-27 mm plus uncoupling mat and covering. This also results in minimal screed material with a surface weight from 40 kg/m2 – which reduces the static load so much that a floor heating system is possible even in historic buildings. Even installation on problematic substrates such as old hardwood floors is not a barrier for our systems.

BEKOTEC-THERM is suitable for any floor covering, so your new floor heating system can also be installed under parquet or vinyl. For the best thermal conductivity and energy efficiency, however, we recommend a ceramic floor made of tiles or natural stone.

Radiant panel heating systems provide cosy warmth without draughts or cold areas in the room – and our complete system even heats floor areas where there are no heating pipes or where they are installed at a greater distance. This is made possible by the DITRA uncoupling mat between the heating screed and the tile covering: it provides many small air channels that distribute the heat even more uniformly. This transforms the floor into a single large radiator, which can also cool if required.

No more cold feet in winter with BEKOTEC-THERM – and if the temperatures in summer cause you to sweat, simply switch over! Set the system to cooling operation via your heating control and, depending on the heat source, use active or passive cooling to keep your rooms at a pleasant temperature silently and without draughts. This lets you reduce the room temperature by up to 3° Celsius in comparison to uncooled rooms – and enjoy your ceramic thermal comfort floor in all seasons.

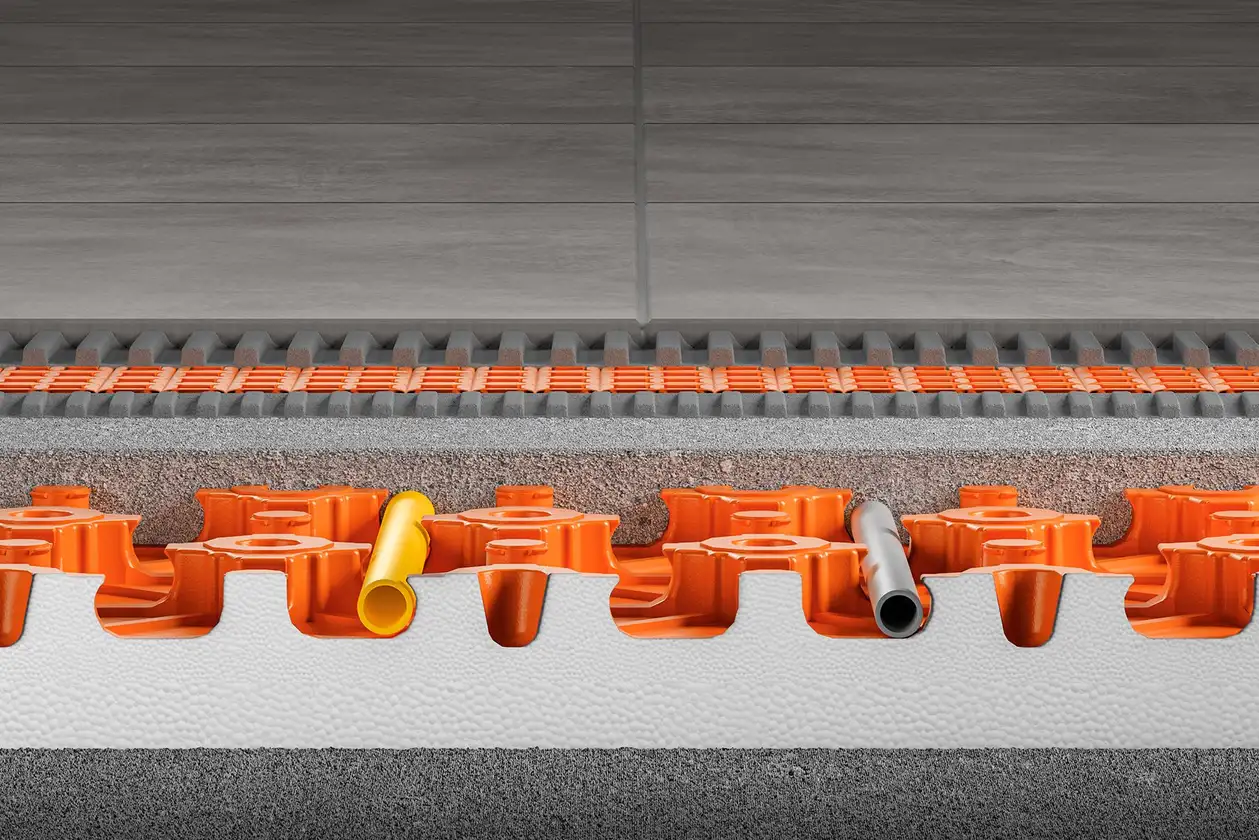

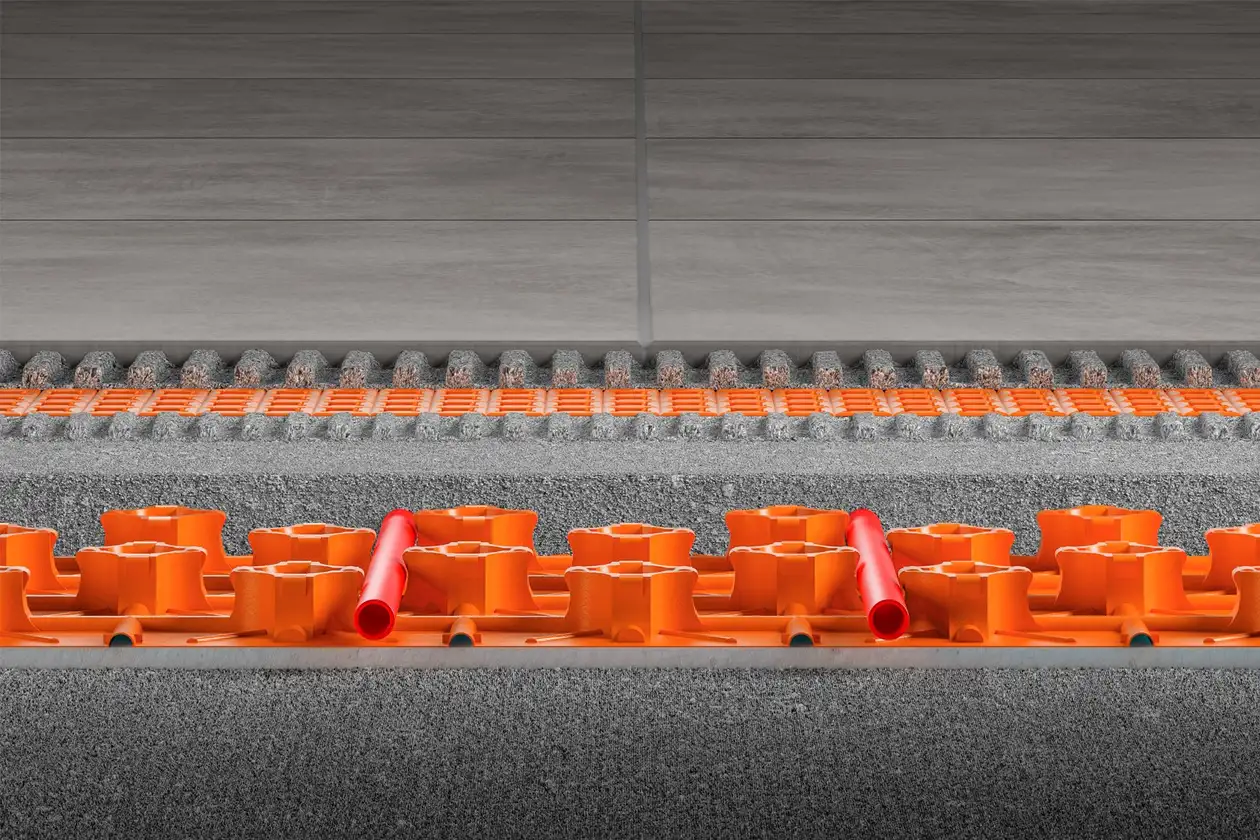

The basis of BEKOTEC-THERM is the Schlüter-BEKOTEC system with the innovative studded panels that are available in five different installation heights. BEKOTEC stands for a reliable covering assembly technology, allowing for functionally safe floating screeds and heated screeds with coverings made of ceramics, natural stone or even other covering materials.

The precisely fitting heating pipes BEKOTEC-THERM-HR are inserted between the studs, then conventional screed is installed with a minimum cover of 8 mm. As tensions are absorbed by the studded pattern of the BEKOTEC studded panels, expansion joints or trowel cuts in the screed – with the exception of structural separations, for example – are not necessary.

Overall, the assembly height to the upper edge of the screed ranges between 20 mm (EN 12 FK) and 61 mm (EN-FI). As a consequence of this minimum height, the floor heating system gets by with a low supply temperature (only 27 to 32 °C) – that saves energy costs in combination with modern heating technology. This minimal use of materials and the elimination of the tedious process of heating the surface for covering shorten the construction time enormously. The floor covering can be installed as soon as the screed is ready to support weight.

Custom-tailored for your needs: BEKOTEC studded panels are available in five variants in different assembly heights, with thermal or impact sound insulation and self-adhesive in part.

With integrated thermal and impact sound insulation (DEO 039) and for flexible installation of Schlüter heating pipes with diameters of 14 and 16 mm.

With integrated insulation (DEO 033) for use in areas with thermal insulation requirements, e.g. over base plate.

Universal assembly for use with and without (sound impact) insulation. Low assembly height, ideal for new construction and renovation.

Our system achieves a sound insulation improvement of up to 25 dB according to DIN EN ISO 10140-1 to optimise impact sound.

Our lightest and thinnest assembly is the best choice for minimal weight. Please contact us if you need options for further assembly weight reduction.

The temperature of each room can be set individually at any time using our temperature controllers so that the preferred temperature is reached in the different areas of your home. In addition, our water-based floor heating system can be programmed using timer control so that it switches on and off at specific times. This is especially efficient if the home is not occupied during the day.

Self-learning systems analyse the heating behaviour and adjust the system settings automatically. Our intelligent actuator BEKOTEC-THERM-EAHB ensures dependable adaptive hydronic balancing, which means that each heating circuit only receives just as much hot water as it needs. This makes heating even more energy-efficient and comfortable.

BEKOTEC-THERM has interfaces to most common smart home systems. This allows you to conveniently control the floor heating system from your smartphone or tablet.

Thanks to our heating circuit distributor, BEKOTEC-THERM can be connected to virtually any heating system. Their full energy-saving potential, however, can be realised by combining it with renewable energy sources – above all heat pumps and solar systems.

Thanks to low supply temperatures, floor heating systems are ideally suited for operation with ecological, renewable heat sources such as heat pumps. The low supply temperatures of BEKOTEC-THERM offer:

The annual output factor of solar systems that are integrated into heating systems increases with every degree the system temperature can be lowered. Due to the lower supply temperatures of BEKOTEC-THERM, the solar system can therefore be used much longer for room heating than is possible with conventional heating systems. On sunny winter days, a properly designed solar system can therefore cover or support the heating system.

| Technical system details | BEKOTEC-EN-FI | BEKOTEC-EN | BEKOTEC-EN-F | BEKOTEC-EN-F-PS | BEKOTEC-EN-FTS | BEKOTEC-EN-FK | BEKOTEC-EN-FK-PS |

|---|---|---|---|---|---|---|---|

| System height in mm (incl. DITRA) | 66–83 | 57–74 | 36–53 | 36–53 | 36–48 | 25–32 | 25–32 |

| Height of the studded panel in mm | 53 | 44 | 23 | 23 | 18 + 5 | 12 | 12 |

| Screed coverage in mm | 8–25 | 8–25 | 8–25 | 8–25 | 8–20 | 8–15 | 8–15 |

| Pipe diameter in mm | 14 / 16 | 16 | 14 | 14 / 16 | 12 | 10 | 10 |

| Installation spacing in mm | 75–300 | 75–300 | 75–300 | 75–300 | 50–300 | 50–300 | 50–300 |

| Heating pipe requirements in m/m² | 13.33–3.33 | 13.33–3.33 | 13.33–3.33 | 13.33–3.33 | 20–3.33 | 20–3.33 | 20–3.33 |

| Max. heat output in W/m² | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Max. weight per unit area in kg/m² | 58 | 57 | 57 | 57 | 52 | 40 | 40 |

| Min. screed volume in l/m² | 28.5 | 28.5 | 28.5 | 28.5 | 26 | 20 | 20 |

| Max. traffic load in kN/m² | up to 5 | up to 5 | up to 5 | up to 5 | up to 5 | up to 5 | up to 5 |

Yes, there is – exclusively from Schlüter-Systems. We are the only manufacturer to offer a 5-year warranty for the entire system. This warranty refers to the screed construction including the crack-free top covering (e.g. for ceramic tiles and natural stone panels).

The components in the screed must be made by Schlüter. That means the studded screed panel, edging strip, system heating pipe and the DILEX-EK or DILEX-RF corner profile must be installed.

The smallest tile sizes 5 x 5 cm. There is no maximum size with Schlüter-BEKOTEC-THERM. For example, you can easily install large-scale pavers with dimensions of 1.5 x 3 metres.

The compressibility value (CP) of all installed components below the BEKOTEC system must be less than 3 mm.

The supply temperature may not exceed 55 °C continuously.

Absolutely! Although ceramic tiles or natural stones are the ideal covering material because of their low thermal resistance, most other floor coverings are feasible in combination with a floor heating system. Soft coverings (linoleum, cork, PVC, vinyl) can be selected to the same extent as parquet and laminate. A large number of manufacturers offer floor coverings that are specifically approved for use with floor heating systems.

Absolutely! Thanks to its low system weight and low assembly height, our floor heating system is ideally suited for renovation and restoration projects in an older home. If a floor area needs to be waterproofed, you can easily accomplish that with the system component Schlüter-DITRA.

Our Technical Department will be pleased to assist you with adapting the floor structure. We can also recommend qualified Schlüter-Systems installers in your local area. Simply contact us!

No expensive special screeds are required for a screed with the Schlüter-BEKOTEC system – commercially available screeds of grade CT/CA C20-C35/F4 (max. F5) without reinforcement can be used, which can be prepared with a screed pump or gravity mixer. Flowing screeds are just as feasible as screeds that are installed when moist.