We're here to help with your construction project

If you'd like us to send more information, whether about our products or services, find out where you can purchase our products, or request a brochure, please get in touch. We're here to help.

Cosy warmth in the winter, pleasantly cool in the summer: Our water-based and electric floor heating systems and wall heating systems maintain a comfortable temperature in your rooms no matter what the season.

Pleasant radiant heat, easy installation and low energy consumption: A floor heating system offers many advantages and is suitable for installation in new construction and renovation projects. Depending on the system, it can even cool them in summer. But what technologies are available, what has to be considered during installation and most importantly – what are the costs and potential savings?

A floor heating system heats the room air by means of heating pipes laid in the floor that are embedded in a heating screed. This type of construction has a multitude of unbeatable advantages and saves valuable resources during operation – as well as heating costs. Because it heats the room over a much larger surface area than a conventional system with radiators, the floor heating system can be operated at a considerably lower supply temperature. Its uniform radiant heat not only feels extremely cosy, but also comes without draughts and, thus, without swirling up dust – a big plus for allergy sufferers.

When thinking about installing a floor heating system, the first thing to consider is the question of the heat transfer medium. The majority of floor heating systems are designed as water-based systems such as BEKOTEC-THERM, where hot water flows through the heating pipes to heat the room. Depending on the required assembly height, requested insulation properties and structural conditions, a choice of thin-layer systems is also available that can be used in old buildings without any problem.

And for smaller areas or for retrofitting in individual rooms, an electric heating system such as DITRA-HEAT-E that uses heating cables and, therefore, electricity as a heat source is also an option. The attraction of these systems is not only that they are easy to install and quick to heat up, but also that they can be installed on walls, in tiled seating areas or in the shower.

When planning your new floor heating system, the selection of suitable floor coverings also plays a role: depending on the material, different floor coverings can transmit the radiant heat from the heating system very differently. In other words, its thermal conductivity has an influence on how quickly a floor heats up and how well the heat is transferred to the room air. Tiles, marble and natural stone floors are particularly well suited due to their low thermal resistance, but parquet, laminate, carpet, PVC or linoleum are also possible. Many manufacturers now offer product variants that have been specially optimised for use via a radiant panel heating system.

Whether the installation is in a new construction, a commercial or public construction project, the renovation of an older structure or even a listed building: every heating project has specific circumstances and special requirements. A qualified, specialist installer with experience of the product is essential for implementing the system and will offer support from consultation and planning to installation and commissioning. We can help in the planning process, from calculating the heat load to the design, and are happy to name distributors or specialist installers in your area who will install our floor heating system for you after individual consultation.

Are you looking for the nearest distributor for your project? We are happy to put you in touch without obligation. On request, our highly trained specialist consultants will present different types of floor heating system for existing structures or new constructions on site. Simply use our Service form for this!

Green spaces, all possibilities: Floor heating systems are now standard in new construction projects and the requirements with regard to substrate, statics, insulation and assembly height are typically covered without any problem. Other factors also play a role, however, in deciding on the right heating system:

The shortest possible construction time with no long waiting times for the screed to dry or heating of the covering.

The sustainable efficiency of the system with regard to conserving resources during installation and operation.

The compatibility of the heating system with regenerative energy sources, such as the use of heat pumps or solar thermal energy.

The potential for use as surface cooling in warm summer months.

In the BEKOTEC-THERM system, a quickly and easily installed studded panel forms the basis for the heating pipes and a thin layer of heating screed. This flooring construction is not only quick to install, but also highly load bearing and low in tension – in private homes as well as in commercial properties such as car dealerships and exhibition halls. For additional comfort between seasons, it can also be combined with an electric heating system such as Schlüter-DITRA-HEAT-E.

When retrofitting a floor heating system in an existing structure, the decision of which heating system to choose depends primarily on four essential factors:

The characteristics of the existing substrate and its possible preparation.

The maximum assembly height of the new floor construction incl. insulation, heating screed, uncoupling mat and floor covering.

The permissible weight of the new floor construction with respect to the screed material to be applied.

The necessity for additional heat insulation to adjacent cold rooms or surfaces.

If a high-quality heating system is required, Schlüter-BEKOTEC-THERM offers suitable studded panels for ultra-flat assembly heights of between 20 mm and 48 mm and a surface weight above 40 kg/m². Schlüter-DITRA-HEAT-E is the ideal solution for heating small rooms or individual comfort zones such as seating areas, shower walls and barefoot areas in front of bathroom fittings – with simple installation and an assembly height of just 5.5 mm.

If a water-based floor heating system is combined with a heat pump, it not only heats, but also cools. Instead of hot water, cold water flows through the heating pipes – and the cooled floor area can draw excess heat out of rooms. The cooling effect may not be quite as strong as that of an air conditioner but it is enough to make you feel comfortable even in summer. Surface cooling does not require any draughts at all, the swirling up of dust or noise and is therefore often regarded as more pleasant by residents.

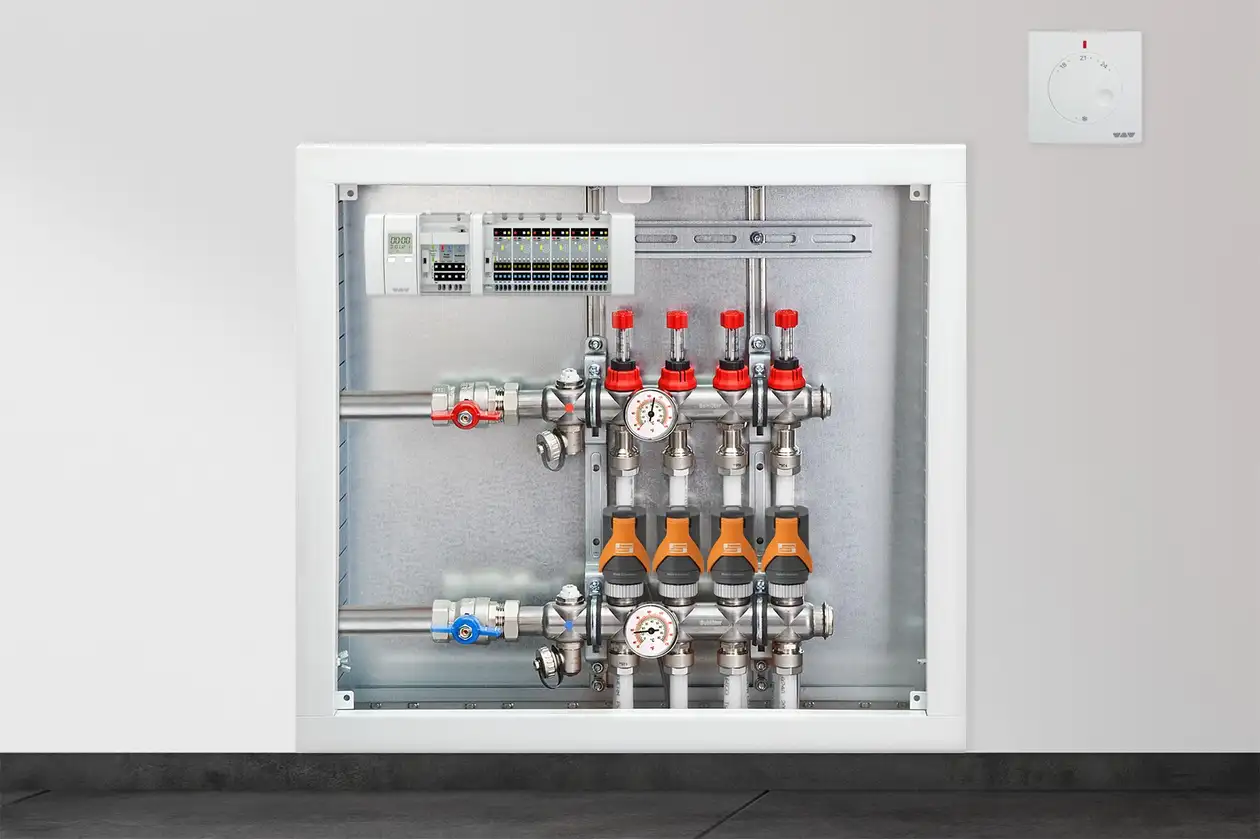

A floor heating system consists of a multi-layer floor construction in which the heating circuits are installed, as well as the associated control and regulation technology for both the energy source and the room temperature.

A water-based system usually involves installing the heating pipes above the insulation on a studded panel in a heating screed. An electric system, conversely, involves laying the heating cables on an uncoupling mat above the screed, and therefore directly under the floor covering. A combination of these two systems is not a problem and is used, for example, to control the temperature of individual areas in the bathroom between seasons without having to activate the complete heating system. Both systems use control technology to connect the heating circuits to the respective energy source and can be controlled via timers, thermostats or smart home applications.

Hydronic balancing is relevant for water-based heating systems in order to optimise the flow behaviour of the water in the heating pipes and thus also reducing energy consumption. This is where static hydronic balancing can help in existing systems: Your specialist installer calculates the amount of heat actually required for each room as well as the hot water volume and pump output required for this. Then it adjusts each individual heating circuit accordingly – and ensures that each room receives exactly the right amount of heating water. Nowadays, there are also intelligent actuators for adaptive hydronic balancing. They control the flow rates in real time and automatically learn over time – this is not only smart, but also really economical.