Schlüter-KERDI-SHOWER-LT / -LTS is a sloped tray made of compression-resistant expanded polystyrene (EPS). It was developed for use with the matching linear drainage system Schlüter-KERDI-LINE (see product data sheet 8.7). The Schlüter-KERDI waterproofing membrane is laminated directly onto the shower tray, which has a sufficiently sloped surface.

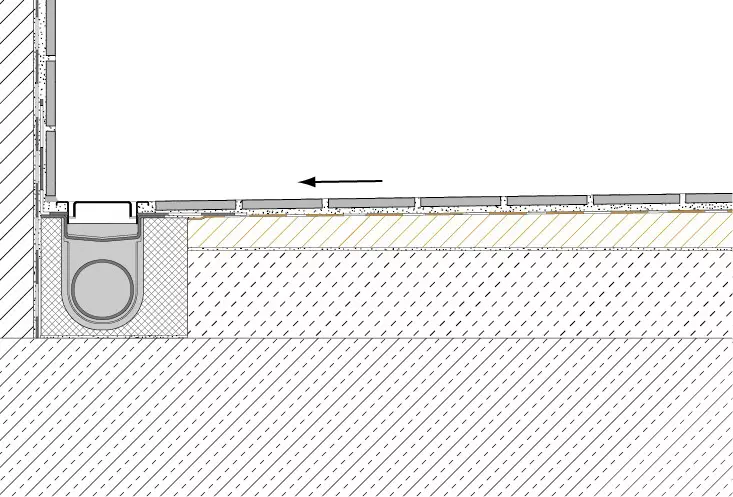

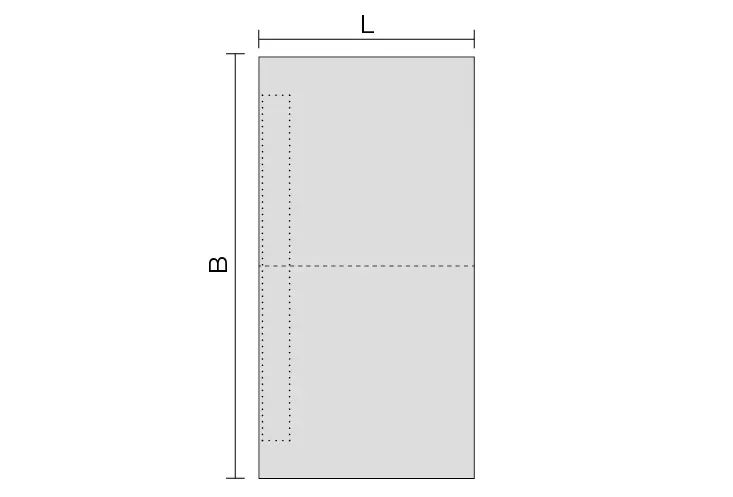

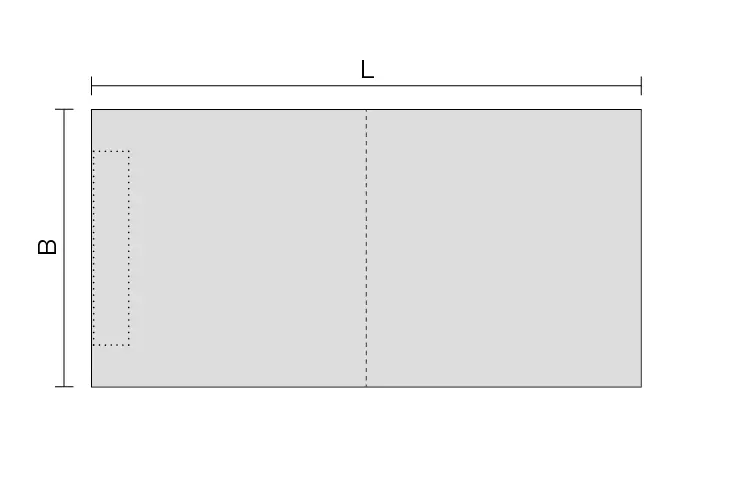

For intermediate installation of a horizontal linear drainage, a customised sloped board (KERDI-SHOWER-LT) is installed on both sides of the linear drainage, or on one side in case of wall installation (KERDI-SHOWER-LTS). For this purpose, a levelling layer made of screed or bound fill must be created on a load-bearing substrate in advance. The assembly height of the levelling layer has to match the corresponding shower tray.

The installation of Schlüter-KERDI-LINE-V for vertical drainage enables low assembly heights from 24 mm.

Individual dimensions can simply be cut to size with a utility knife, using the pre-marked cutting grooves. Depending on the application at the construction site, the sloped tray can be used with the corresponding, load-bearing substrates (e.g. wooden studs, vertical drain, mortar substrate etc.).

The available tray dimensions for wall installation include:

- 91.5 x 139.5 cm

- 91.5 x 183 cm

- 96.5 x 193 cm

- 100 x 100 cm

- 122 x 122 cm

- 136.5 x 200 cm

- 139.5 x 139.5 cm

- 193 x 96.5 cm

The available tray dimensions for intermediate installation include:

- 100 x 100 cm

- 122 x 122 cm

- 139.5 x 139.5 cm

(drainage is always situated on the first listed side)