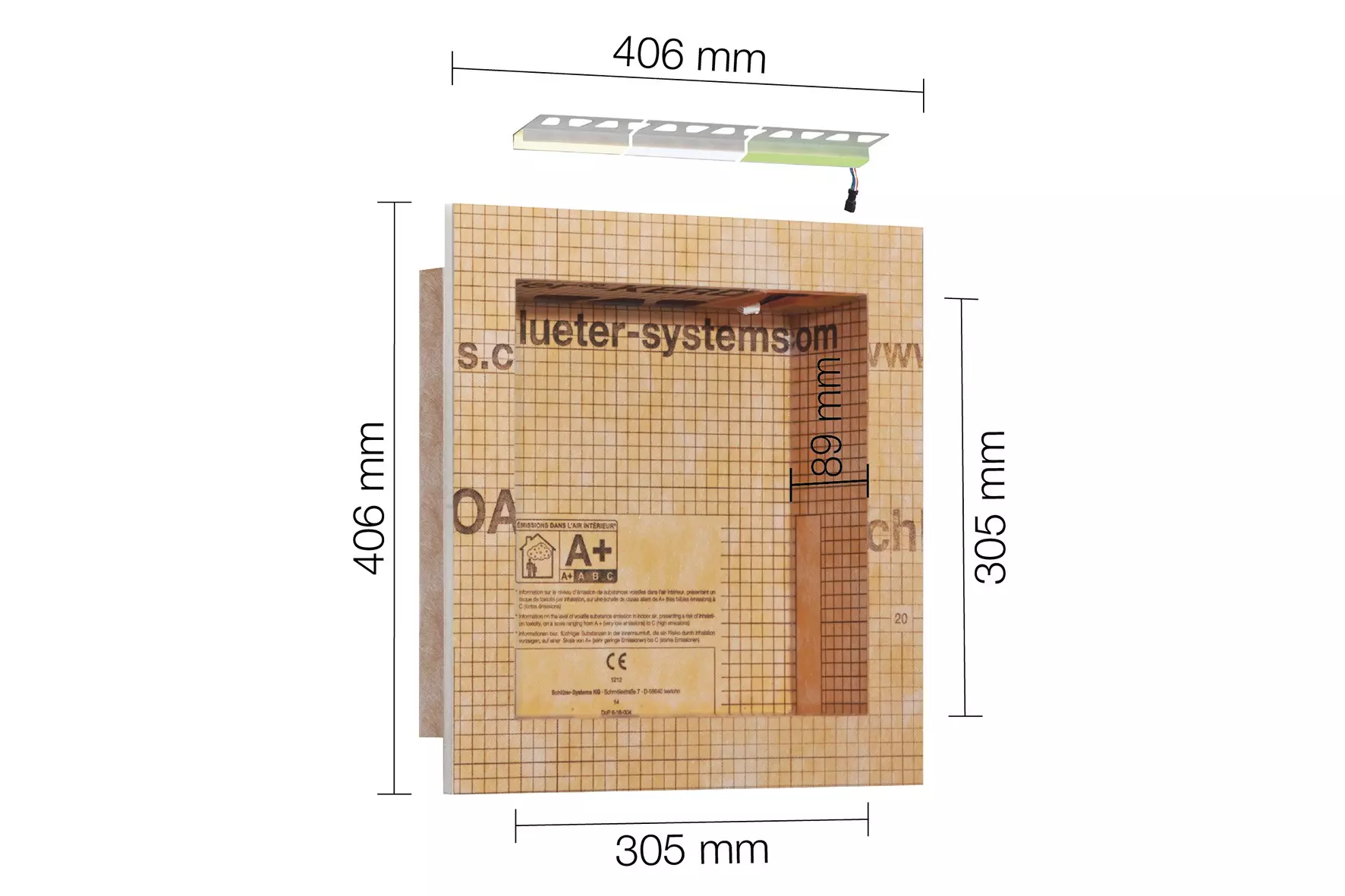

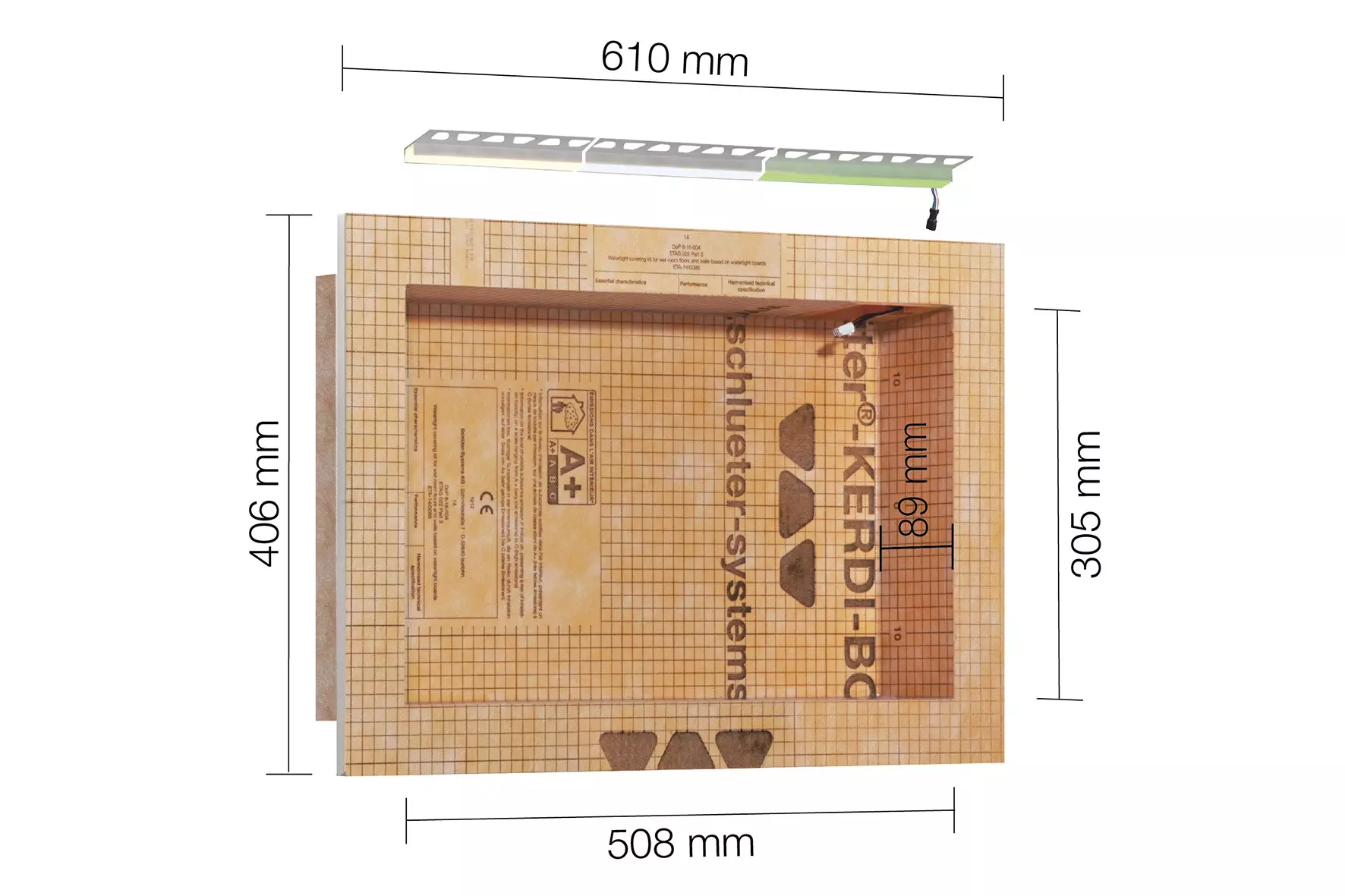

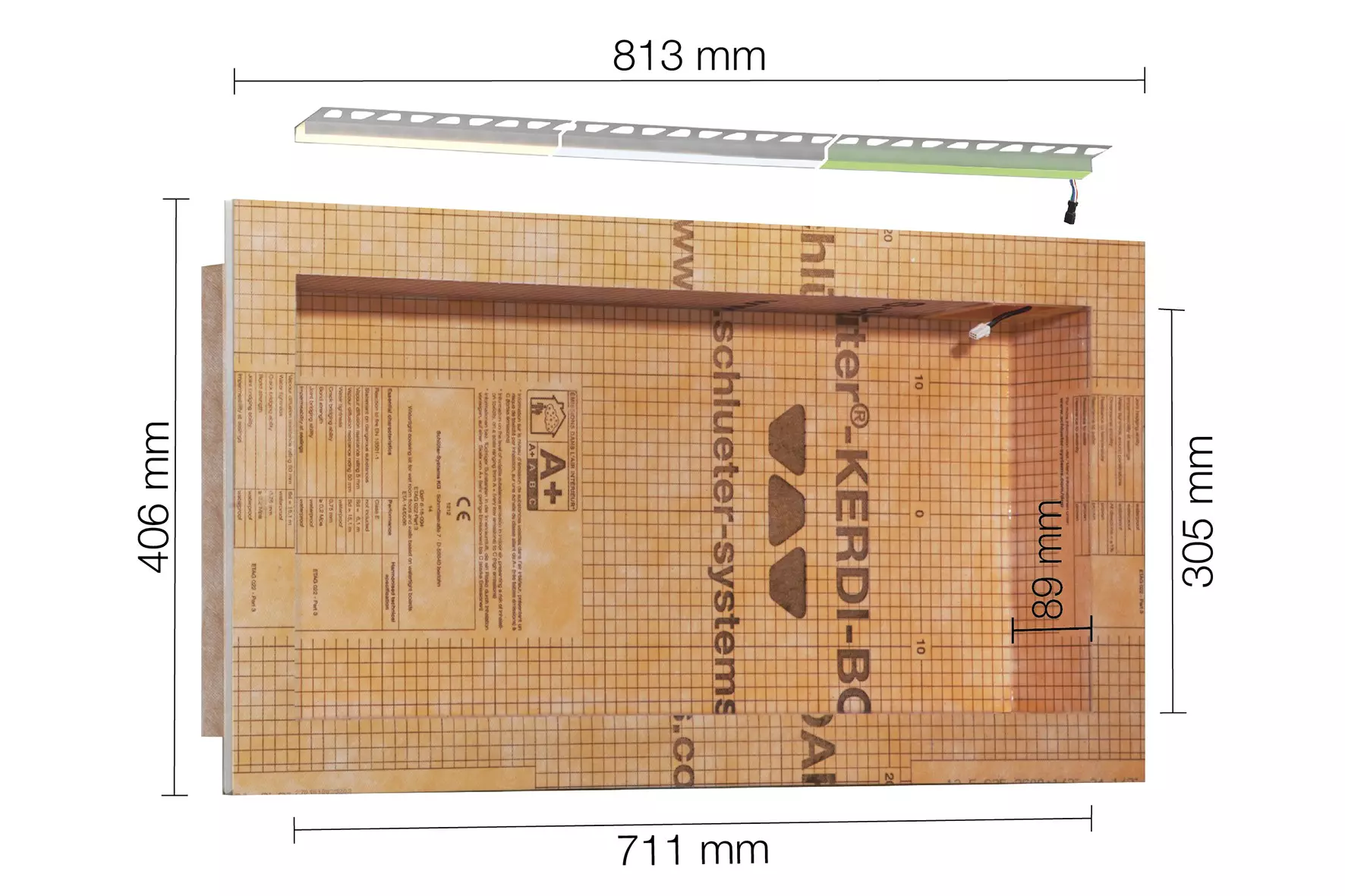

Schlüter-KERDI-BOARD-NLT is a panel of extruded rigid XPS foam with a thickness of 12.5 mm, laminated on both sides with a special, cement-free reinforcement material and a fleece fabric for effective anchoring of thin-bed mortars or rendered covering materials. One surface of the board is printed with 10 x 10 mm gridlines.

Material properties and areas of application

KERDI-BOARD-NLT is waterproof and resistant to any chemical stresses that typically occur in conjunction with tiled coverings. Where required, certified bonded waterproofing can be created in conjunction with Schlüter-KERDI or KERDI-BOARD.

KERDI-BOARD-NLT is completely flat and even when exposed to temperature or moisture fluctuations on one side will not warp, is ageing-resistant and highly stable.

KERDI-BOARD-NLT is ideal for a wide variety of applications.

Substrates should be checked for sufficient stability and other project-related requirements.

In special cases, the suitability of Schlüter-LIPROTEC modules should be verified on the basis of the anticipated chemical or mechanical stresses. The information below can only serve as a general guideline.

Anodised aluminium: Thanks to the anodising, the aluminium features a refined finish that retains an unchanging appearance during normal use.

Aluminium is sensitive to alkaline media.

Cementitious materials, in conjunction with moisture, become alkaline. Depending on the concentration and length of exposure, this may result in corrosion (aluminium hydroxide formation).

For this reason, remove mortar or grouting material immediately from all visible areas and do not cover freshly laid coverings with foil.