- The substrate must be level, load-bearing and free of components that may inhibit bonding. Any necessary levelling work must be completed before installing DITRA.

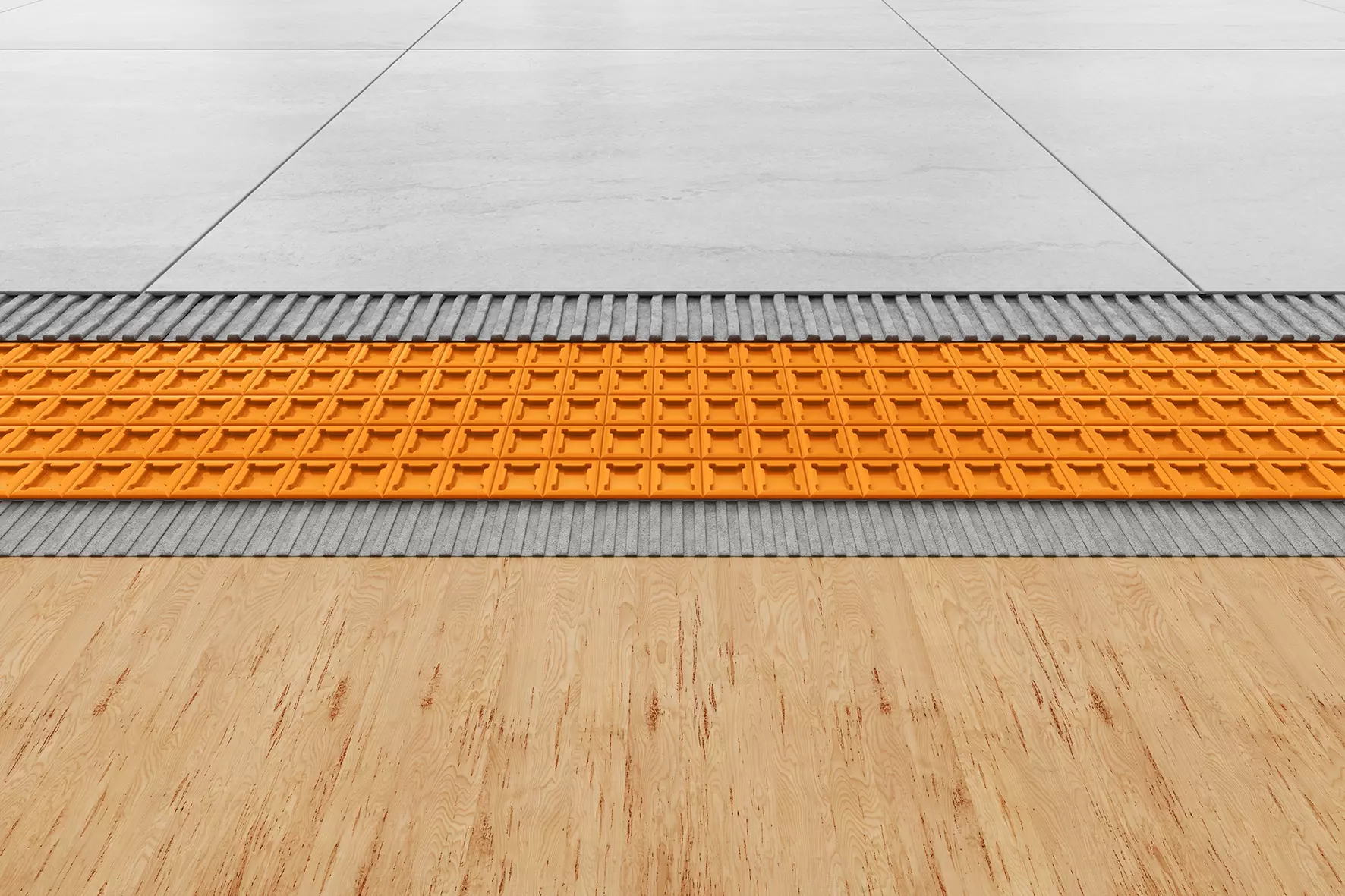

- The selection of the adhesive for installing DITRA depends on the substrate. The adhesive must bond with the substrate and mechanically attach to the DITRA anchoring fleece. A dry setting cementitious tile adhesive can be used for most substrates. The adhesive should preferably have a consistency suitable for fluid beds. Review any potential material incompatibilities beforehand.

- The cementitious tile adhesive should be applied on the substrate with a notched trowel (recommended size: 3 x 3 mm or 4 x 4 mm; adhesive requirement approx. 1.5 kg/m²).

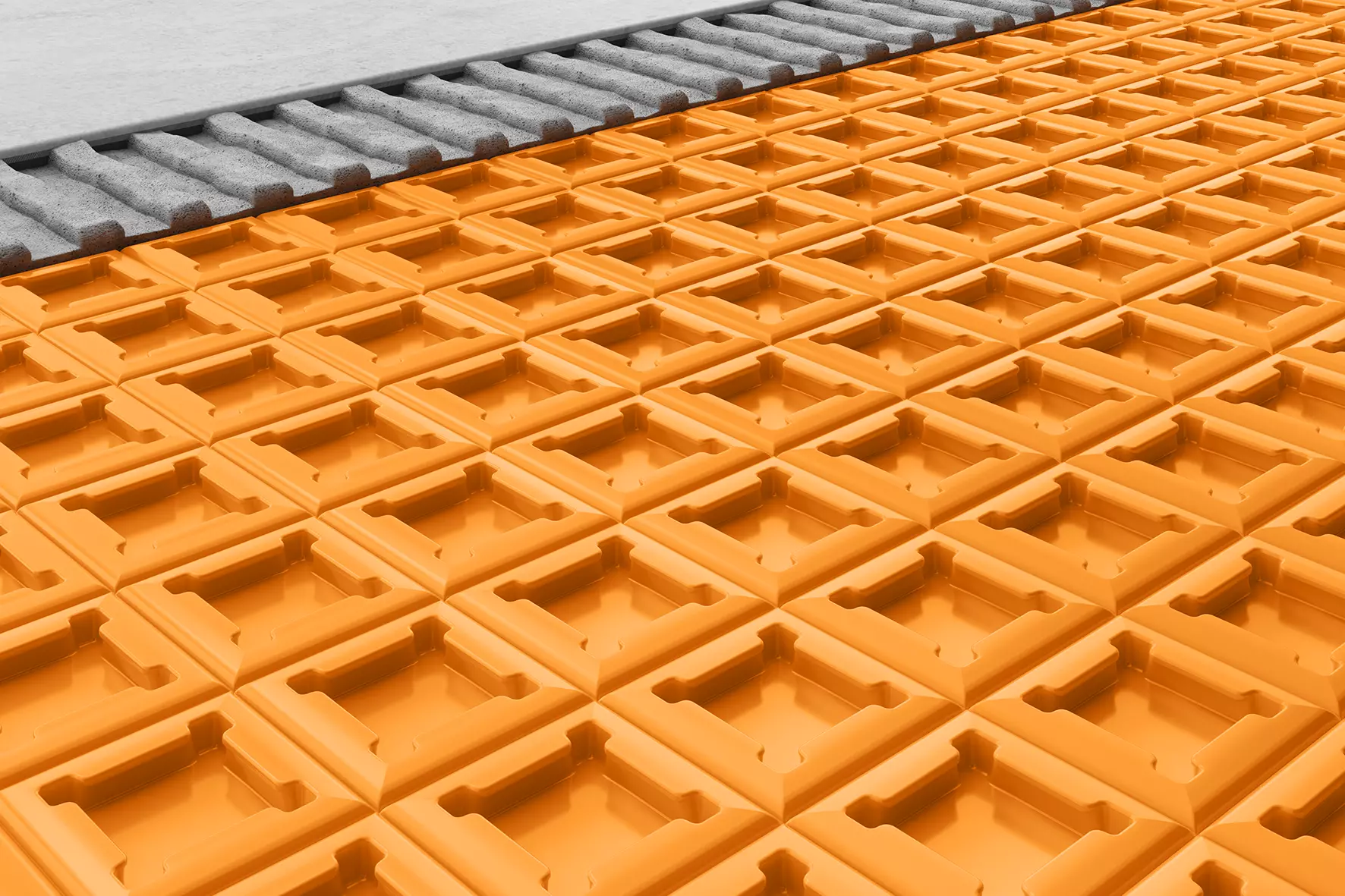

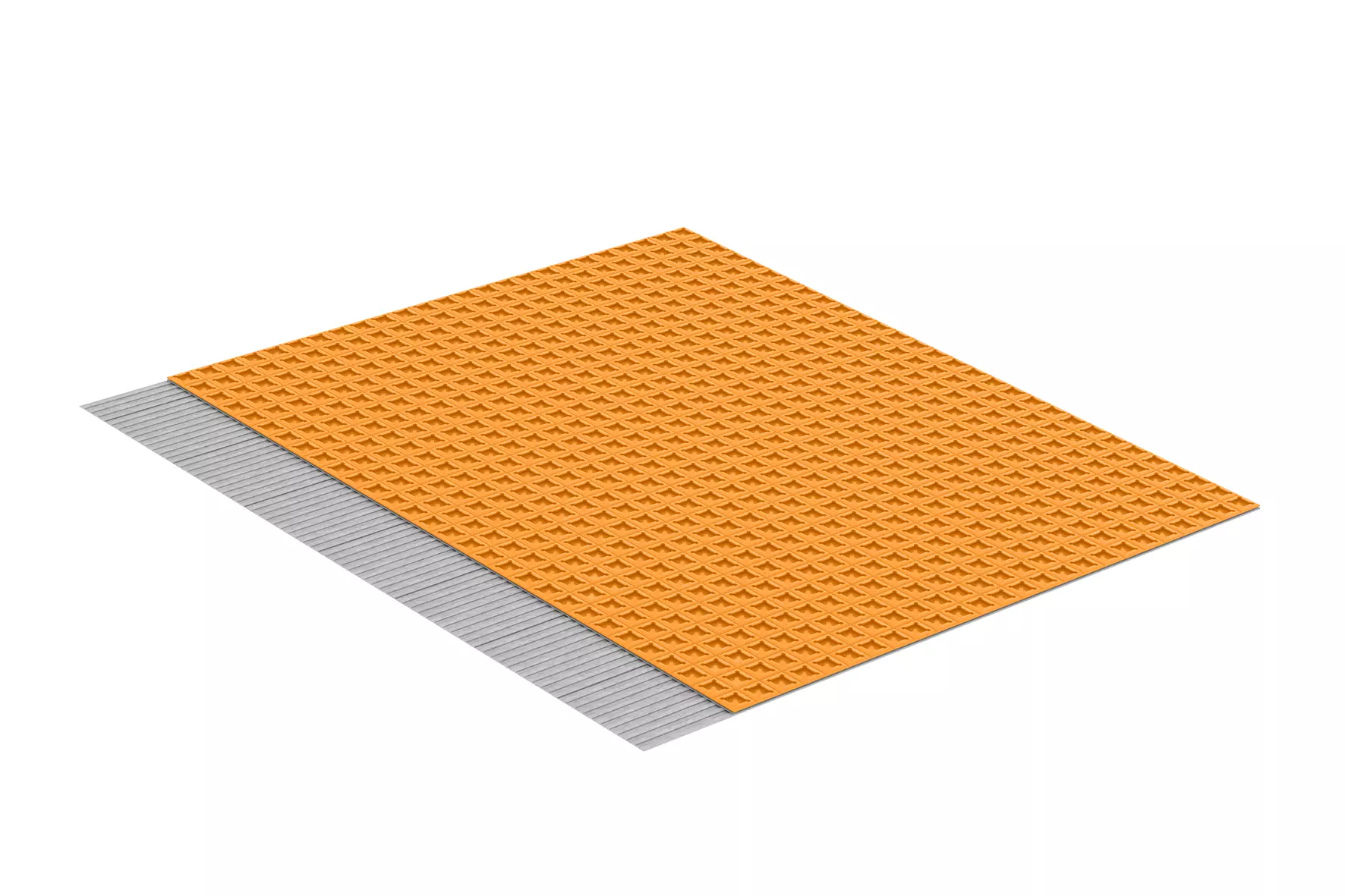

- Embed the DITRA membrane, which must have been cut to size beforehand, into the installed adhesive with the anchoring fleece facing down. Immediately press the membrane in place with a float or roller, working in a single direction. Orbital sanders can also be effective tools. The curing time of the adhesive must be observed. For efficient installation, precisely align DITRA and keep the material tightly stretched with light tension when placing it on the substrate.

The EasyCut gridlines of the membrane assist with allowing the membrane to lie flat on the substrate.

A second helper can make installation easier. The individual mats are installed with closely abutting joints.

Note: if Schlüter-DITRA is to be used for uncoupling and waterproofing, abutting joints and connections must be sealed with the relevant system components. Further details can be found in the notes on waterproofing.

The same applies for using DITRA on green substrates in conjunction with coverings that are susceptible to discoloration.

- To prevent any damage to the installed DITRA mat or detachment from the substrate, it is recommended to protect the area from mechanical stresses, e.g. by setting out running boards (particularly in the centre areas used for material transport). Special protective measures may be necessary for outdoor installations, e.g. to shield against direct sunlight or precipitation. Remove any accumulated water in the recesses indentation before applying the cementitious tile adhesive.

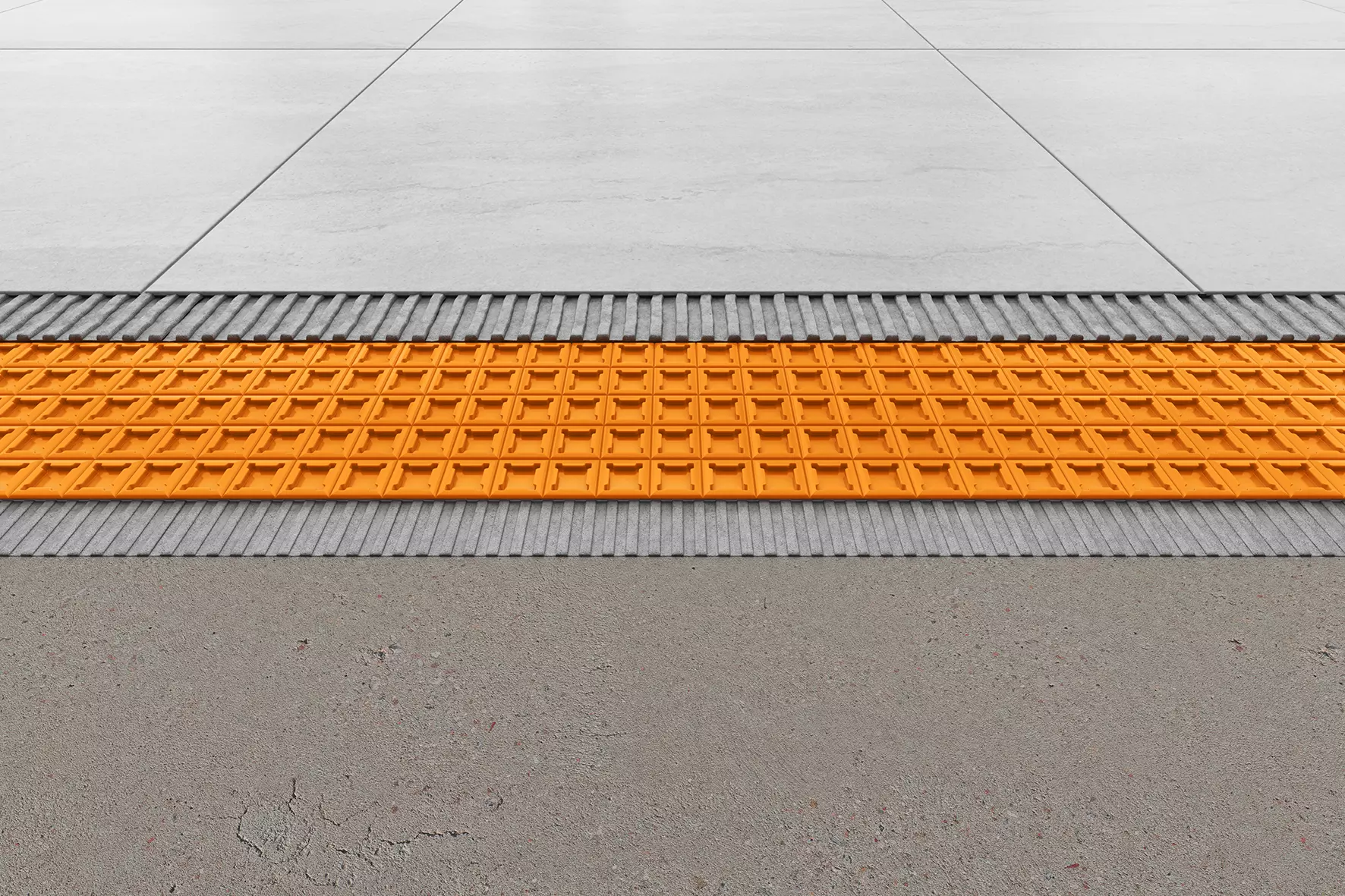

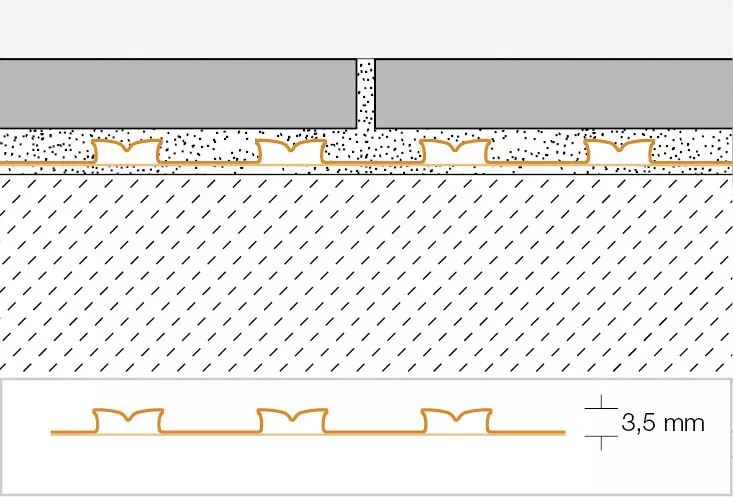

- Immediately after adhering the DITRA mat, tiles can be installed using the thin-set method, with a cementitious tile adhesive that meets the requirements of the respective covering. The notch size of the trowel must match the tile format. Observe the curing time of the adhesive. All tiles must be solidly embedded in the adhesive. Full contact according to the applicable professional regulations is especially relevant for coverings exposed to high mechanical stresses and in outdoor areas.

Note: Fill the square recesses with the smooth side of the notched trowel (adhesive requirement approx. 2.0 kg/m2) and then groove the cementitious tile adhesive with the notched side of the trowel in a single action. Tile installation can begin once the trowelled surface is ready to bear weight. Note that the substrate must be free of dust for the installation. If applicable, vacuum the substrate prior to installation or apply a primer in case of doubt.

Review any potential material incompatibilities beforehand. If using covering materials with a side length over 30 cm, we recommend a quick-setting tile adhesive with crystalline water binding capacity for fast curing and drying of the adhesive.

- Follow the instructions in this data sheet and other relevant technical regulations to install movement joints for perimeter, edge and transition profiles.

Waterproofing with Schlüter-DITRA

DITRA can be used to create certified waterproofing assemblies with tile coverings, provided the abutting membrane joints and the connections to installed components and upright building structures are carefully sealed. DITRA can be installed in accordance with the waterproofing standards 18531-5 or 18534 applicable in Germany. Water exposure classes: W0-I to W3-I. DITRA also features the national technical approval (abP) required in Germany.

System-certified tile adhesives must be used in areas that require compliance with abP (certificate of technical approval). Please contact us at the address listed in this data sheet for further information about such tile adhesive products and the corresponding certificates of technical approval. We recommend the use of our waterproofing membrane Schlüter-KERDI (see the Schlüter-KERDI page) for load class B, "Swimming pools".

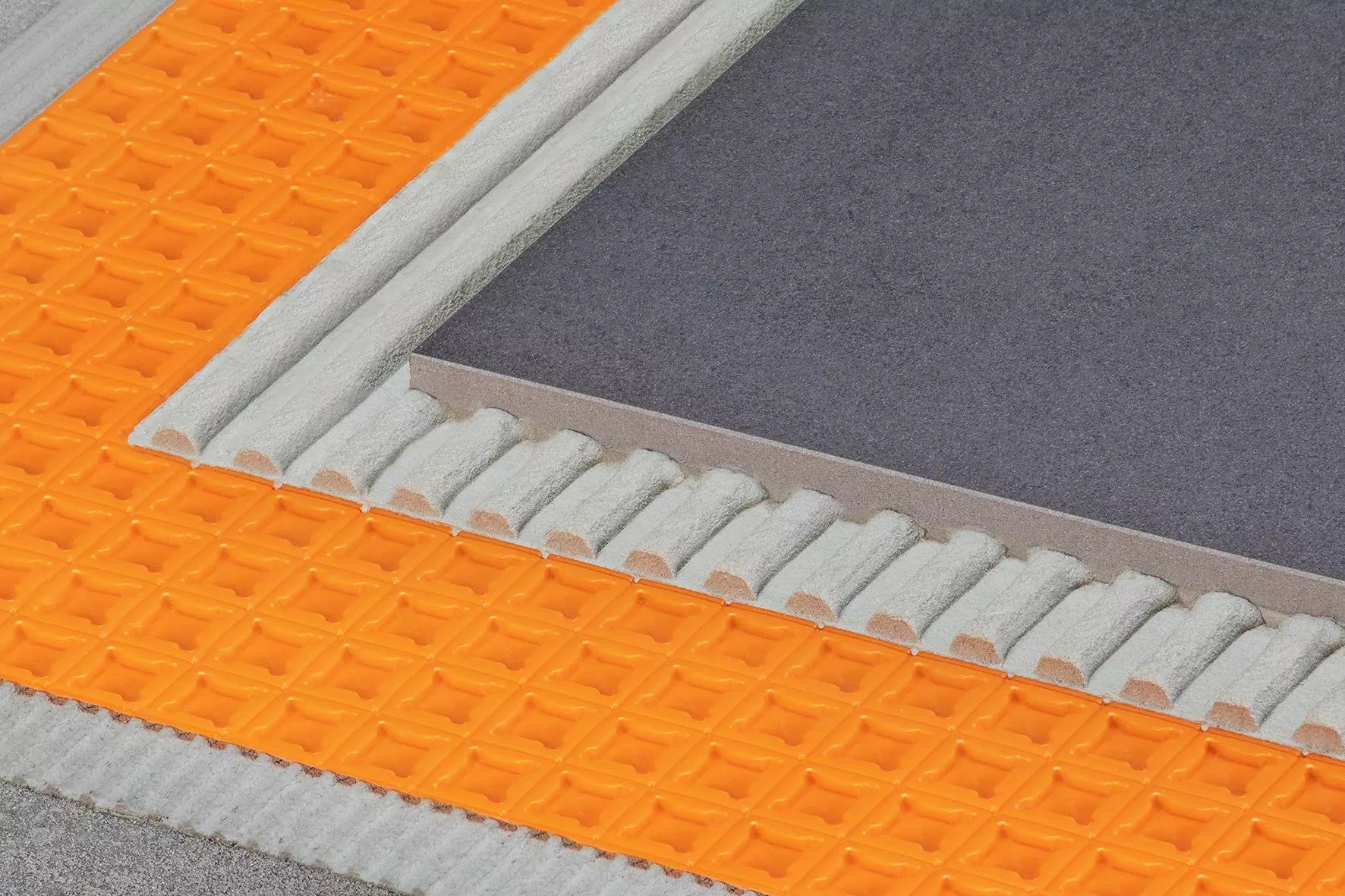

DITRA protects the substrate from damage caused by permeating moisture and aggressive substances. For joint sealing, trowel the sealing adhesive Schlüter-KERDI-COLL-L over the abutting joints and fully embed KERDI-KEBA in a minimum width of 12.5 cm over the joint.

To waterproof floor-wall transitions, adhere KERDI-KEBA over DITRA on the floor and directly on the substrate in wall areas in the corresponding width.

The sealing band should have a coverage of at least 5 cm.

KERDI-KEBA can also be used to create functional connections to fixed structural components such as door and window frames as well as balcony edge profiles made of metal, wood or plastic. The first step is to apply Schlüter-KERDI-FIX to the adhesive surfaces of the structural elements.

The remaining width is then adhered to DITRA with KERDI-COLL-L.

The suitability of KERDI-FIX for the respective materials of the structural elements must be verified in advance.

Separate DITRA at existing movement joints or expansion joints and seal the abutting joints with KERDI-FLEX.

KERDI-FLEX should also be used for flexible finishing edges. As an alternative, this can also be done with a sufficient loop of KERDI-KEBA.

Note on floor drains

Schlüter-KERDI-DRAIN and Schlüter-KERDI-LINE are special drainage systems designed for connection to bonded waterproofing assemblies. Schlüter-DITRA can easily and quickly be combined with these components using pre-fabricated KERDI collars.

Substrates for Schlüter-DITRA

Always check the substrates on which DITRA is to be installed to make sure they are level, rigid, load-bearing, clean and compatible with the materials to be used. Remove all surface components that may weaken the bond. Any levelling, height adjustment or slope compensation must be carried out before installing DITRA.

Concrete

Concrete undergoes long-term structural deformation due to shrinkage. In addition, tension can build up in concrete and pre-stressed concrete due to deflection. Since DITRA absorbs the resulting tensions between the concrete and the tile covering (in wall and floor areas), tiles can be installed as soon as the concrete is ready to bear weight.

Cement screeds

In accordance with the applicable regulations, cement screeds must have cured for at least 28 days prior to tile installation and have a moisture content below 2 CM %. Floating and heated screeds have a particular tendency to buckle and crack even later, e.g. due to mechanical stresses and temperature fluctuations.

With DITRA, tiles can be installed on green cement screeds as soon as they are ready to bear weight.

DITRA will neutralise cracks and screed deformations developing later and will prevent them from affecting the tile covering.

Gypsum based screeds

According to the applicable rules, gypsum based (anhydrite) screed may not have a residual moisture level of more than 0.5 CM % at the time of tile installation. In contrast, tile installation is permissible from a residual moisture level of 2 CM % with DITRA.

If necessary, the screed surface must be treated (grinding, priming) as specified by the applicable technical regulations and manufacturer instructions. DITRA can be installed with dry-setting or other suitable cementitious tile adhesives. It protects the screed surface against permeating moisture. Because gypsum based screeds are susceptible to moisture, screeds must be protected against humidity, e.g. moisture seepage on the underside.

Heated screeds

DITRA can be used on heated screeds, provided the above notes (cement, gypsum based screeds) are followed. Covering assemblies created with DITRA are ready for heating only 7 days after completion. Starting from a temperature of 25 degrees C, the supply temperature can be increased by no more than 5 degrees C a day to a usage temperature of max. 40 degrees C. The interconnected air channels of the DITRA membrane quickly and evenly distribute the heat below the tiles.

Note:

For floor heating systems, please refer to our ceramic thermal comfort floor system Schlüter-BEKOTEC-THERM.

DITRA is also recommended for uncoupling floor heating systems comprising thin electric heating mats. In those cases, DITRA can be installed above or below the heating mat. However, an installation above the heating mat achieves better uncoupling effects. Please note that the bedding above the mat should not exceed 10 mm.

Schlüter-DITRA-HEAT was developed specifically as an uncoupling mat designed to attach the matching system heating cables for electric floor/wall heating systems. Further details can be found on the DITRA-HEAT page.

Screed boards and composite panels

After the proper installation of dry screed elements according to manufacturer instructions, any tile format may be chosen to install with DITRA.

Masonry / mixed substrates

Masonry structures built with bricks, sand lime bricks, cement blocks, aerated concrete or similar materials is generally a suitable substrate for DITRA. The surface must be levelled in advance. In restoration and refurbishment projects, substrates frequently consist of different materials (mixed masonry), which have a tendency to crack at the interfaces with other materials due to different deformation rates. DITRA protects the tile covering from the resulting tensions and cracks.

Gypsum plaster / bricks

Gypsum substrates should be completely dry in accordance with the relevant regulations. The surface may need to be pre-treated with a primer. DITRA can be installed with dry-setting or other suitable cementitious tile adhesives.

Balconies / terraces

As an uncoupling mat, DITRA neutralises the tensions between the substrate and tile covering that can be caused on balconies by frequent, significant temperature fluctuations. In addition, DITRA can serve as the sole waterproofing assembly in conjunction with the tile covering in cantilevered balconies and terraces built directly over the ground, which are only used for residential purposes (observe notes on waterproofing). In that case, the substrate (concrete, screed) must have a sufficient slope.

If previous coverings are sufficiently weight bearing and have the necessary slope, the existing assembly may be used as the substrate in renovation projects. Otherwise, loose or insufficiently bonded parts must be removed prior to installing DITRA and any flaws or inadequate slope must be corrected with a suitable ready-mix mortar.

The use of Schlüter-DITRA-DRAIN is recommended for coverings with dimensions exceeding 30 x 30 cm (see the DITRA-DRAIN page).

Roof terraces

Roof terraces situated above residential/utility spaces and other areas as well as the roof spaces must first be installed as a flat roof in accordance with the applicable building regulations for roof assemblies.

In case of heat-insulated residential or utility spaces (and rooms with anticipated temperature differences to the outdoor space), a standard-compliant vapour barrier and top waterproofing layer are required. The provisions of any applicable national standards and/or relevant codes must be observed. A drainage (Schlüter-TROBA or Schlüter-TROBA-PLUS) must be arranged over the top waterproofing assembly. This is topped with a screed as the load distribution layer. DITRA is installed on the screed surface to uncouple the tile covering and protect the screed from moisture. As an uncoupling mat, Schlüter-DITRA neutralises the tensions between the substrate and tile covering that can be caused on terraces by frequent, significant temperature fluctuations.

The use of DITRA-DRAIN is recommended for coverings with dimensions exceeding 30 x 30 cm (see the DITRA-DRAIN page).

Vinyl coverings and coatings

All surfaces must be load bearing and pre-treated or suitable for bonding with an appropriate adhesive, in which the DITRA anchoring fleece can be embedded. The compatibility of the adhesive with the substrate and with DITRA must be verified in advance.

Plywood, chipboard and compressed wood panels

These materials undergo significant deformation based on the influence of moisture (or fluctuations in humidity). It is therefore recommended to use plywood, chipboard and compressed wood panels with special water-repellent treatment. Such panels can generally be used as a floor and wall substrate in interior spaces. Refer to local regulations if these are acceptable. However, they have to be thick enough to be sufficiently stable in conjunction with a suitable support assembly. The structure should be fastened with closely spaced screws. Abutments must have a tongue and groove connection and be fully sealed. Perimeter movement joints of about 10 mm have to be maintained at the transition to upright building structures. DITRA neutralises any tensions with the tile covering and also prevents permeating moisture.

Hardwood floors

In principle, ceramic coverings can be directly installed on sufficiently weight bearing, screw-fastened hardwood floors with tongue and groove connections. The wooden substrate should have balanced moisture levels before DITRA can be installed. It has proven beneficial to install an additional layer of plywood. Uneven floor surfaces should be levelled with suitable measures beforehand.

Flooring grade asphalt (bitumen) screeds

DITRA enables the installation of ceramic coverings over weight bearing, unheated mastic asphalt screeds in indoor areas, provided they were installed in compliance with the relevant standards. Surfaces must be sanded or be suited for sufficient bonding of the cementitious tile adhesive with DITRA.