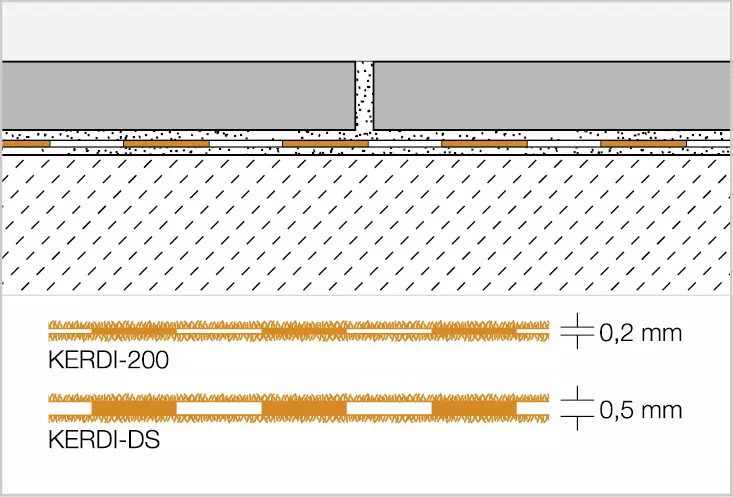

Schlüter-KERDI is a crack-bridging waterproofing membrane of soft polyethylene with a special fleece fabric laminated on both sides for effective anchoring in the tile adhesive.

KERDI features imprinted gridlines on one side for easier cutting. In addition to indicating how much material is left, the imprint also shows the minimum overlap width of 5 cm for working with multiple membrane sheets.

The KERDI waterproofing system holds a European Technical Assessment (ETA) in accordance with EAD 030400-00-0605 and a certificate of technical approval for the German market (abP) and bears a CE mark. Schlüter-KERDI can be installed in accordance with the waterproofing standard DIN 18534 applicable in Germany. Water exposure classes: W0-I to W3-I*. KERDI also features the national technical approval (abP) required in Germany.

Moisture load class according to ZDB: 0 to B0 as well as A, B and C.

KERDI features European Technical Approval (ETA) pursuant to ETAG 022 (watertight covering kits) and bears a CE mark.

* With abP and/or based on ETA as per EAD 030400-00-0605. Further information on use and installation is available on request from our Technical Department.

The waterproofing membrane should be bonded to an even, load bearing substrate with an appropriate adhesive. Tiles are then installed directly on KERDI, using the thin-bed method. Other suitable trowel-applied covering materials or plaster may also be used.

Schlüter-KERDI-DS is a waterproofing membrane and vapour barrier bonded to a tile covering, e.g. for use in swimming pools and spa areas, as well as for commercial applications with high humidity levels.

Vapour barriers are suggested for moisture-sensitive substrates such as wood, plasterboard and gypsum plaster.

Accessories for KERDI include internal and external corners as well as pipe collars, Schlüter-KERDI-KM and Schlüter-KERDI-MV. Schlüter-KERDI-PAS sets – consisting of a KERDI-MV collar and a special plastic sleeve – are available for installations involving existing pipe protrusions located within the waterproofing plane that are to be fitted with an internally threaded tap extension. To seal butt joints or corner joints, Schlüter-KERDI-KEBA, in widths of 8.5, 12.5, 15, 18.5 and 25 cm are available.

Schlüter-KERDI-FLEX, in widths of 12.5 cm or 25 cm, is used to seal over expansion joints or flexible edge joints.