The application area must be weight-bearing and sufficiently solid. The surface where the adhesive is to be applied must be suitable for adhesives and bonding, solid and free of loose debris. Materials must not include any volatile components that may interfere with the bond later. If applicable, conduct your own testing on site to verify suitability.

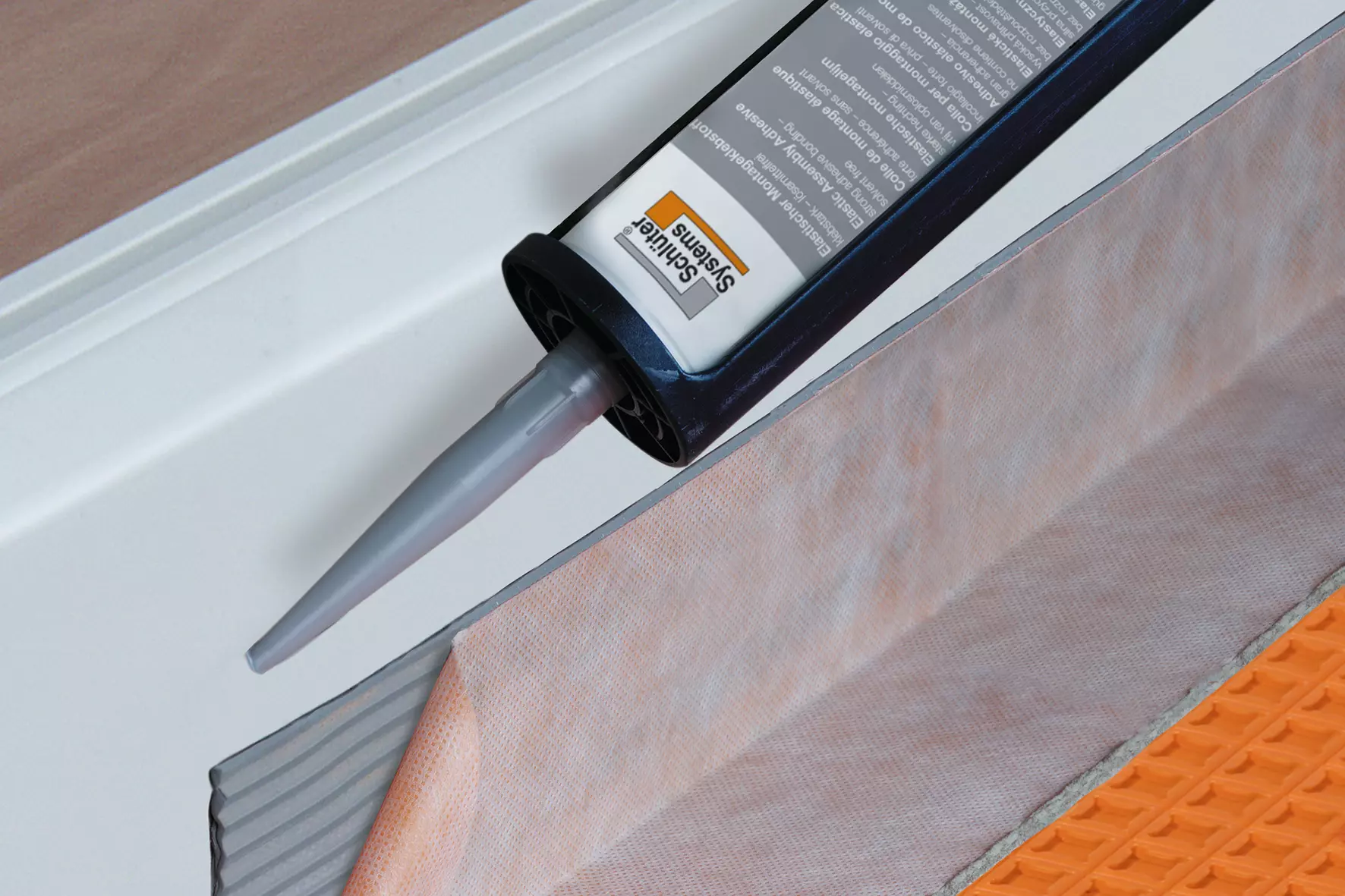

Schlüter-KERDI-FIX as an installation adhesive

Apply Schlüter-KERDI-FIX as a line or spot. For complete curing on non-absorbent or extremely dry materials, KERDI-FIX can be moistened with water. Fit together the components to be adhered during the skin-forming time; spraying KERDI-FIX with water significantly shortens the skin-forming time. If necessary, secure the work pieces in an undisturbed location until the adhesive has fully cured.

Schlüter-KERDI-FIX for waterproofing

To adhere Schlüter-KERDI or KERDI system components, apply KERDI-FIX on the substrate and evenly spread it with a finely notched trowel. Fully embed the materials to be adhered as quickly as possible, avoiding all cavities.

We recommend drawing the smooth side of the notched trowel over the KERDI membrane or using a suitable pressure roller for adhering the KERDI material. Make sure there are no air bubbles.

Schlüter-KERDI-FIX as an exposed joint

Properly cover all edges, e.g. with masking tape, prior to applying KERDI-FIX to joints. The tape may not reach into the joint. To avoid three-point adhesion, press a backfill line with a suitable diameter into the joints.

Fill the joint with KERDI-FIX without leaving any cavities. Remove any excess material with a trowel. Then remove the adhesive tape and smooth the joint with the help of water or a suitable smoothing agent.

Note: Exposed joints require maintenance.