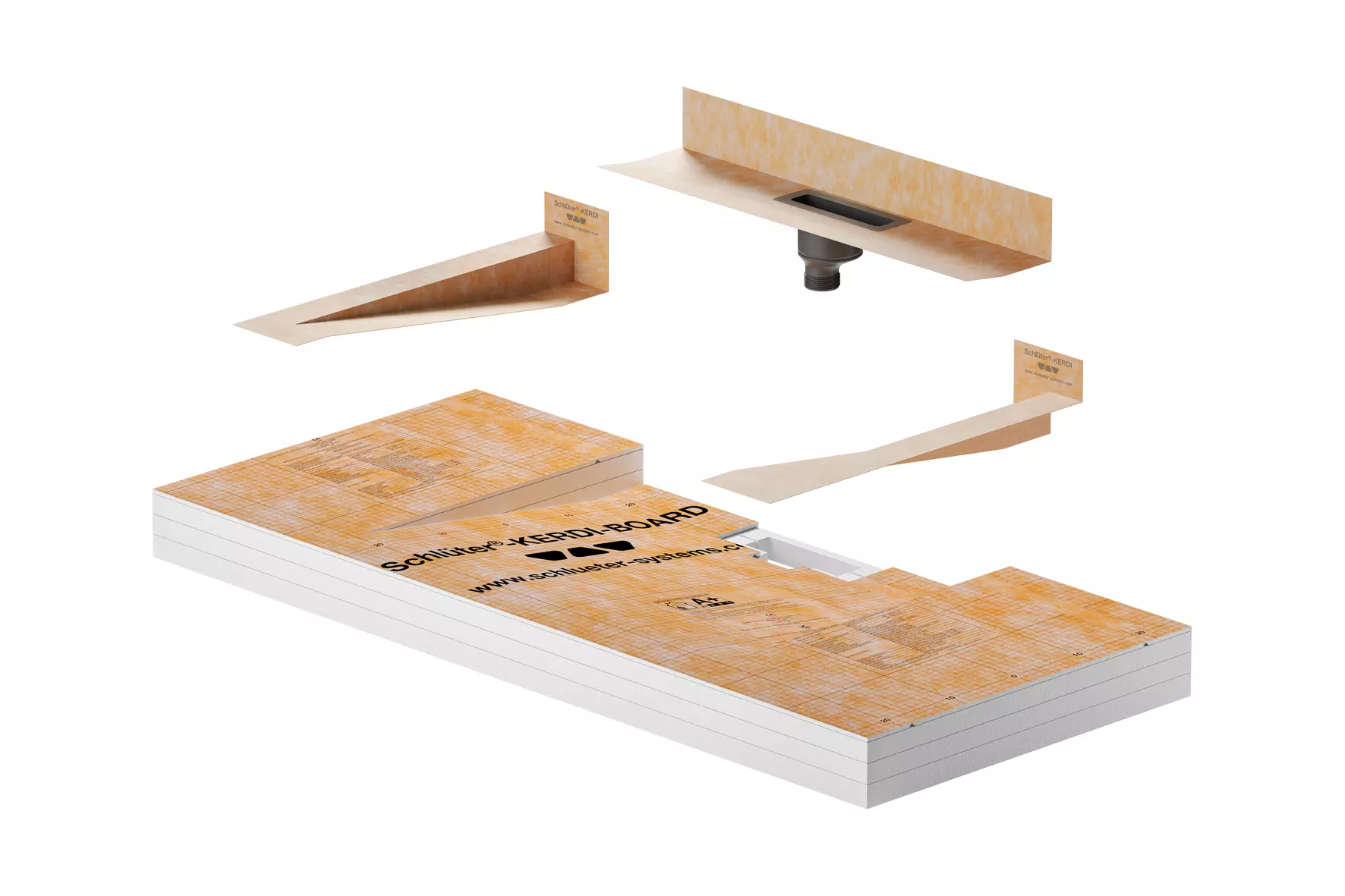

Schlüter-KERDI-BOARD-WW and -WS are a composite material and consist of four layers of extruded rigid XPS foam with board thicknesses of 28 mm, 2x 25 mm and 5 mm (KERDI-BOARD-WW) or 28 mm, 27 mm, 25 mm and 5 mm (KERDI-BOARD-WS). The surfaces of the 28 mm and 5 mm boards are laminated with a special, cement-free reinforcement material and a fleece fabric on both sides for effectively anchoring thin-bed mortars or rendered covering materials. The fabric features a 10 x 10 mm printed gridline pattern for easier cutting. The boards are fully bonded. KERDI-BOARD-WS also has an integrated reinforcement layer to stabilise the fitting.

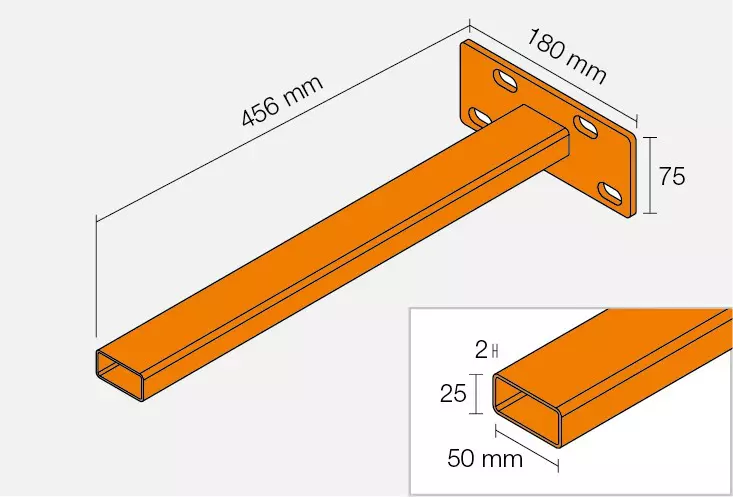

The brackets consist of a 6 mm thick flange and a rigidly welded rectangular tube of dimensions 50 x 25 x 2 mm. Both parts are made of galvanised structural steel 235JR.

The connection adapter is made of highly impact-resistant PP (polypropylene).

The KERDI waterproofing collar that is bonded on the drain adapter and the prefabricated moulded KERDI-KERS corner parts for connecting to the bonded waterproofing is made from a polyethylene membrane.

The triangular profiles made of brushed stainless steel V4A or aluminium with a high-quality powder coating have fleece on the back for anchoring in the tile adhesive.

Material properties and areas of application:

The surface of the Schlüter®-KERDI-BOARD vanity units is waterproof and resistant to any chemical stresses that typically occur in conjunction with ceramic tiled coverings. Where required, certified bonded waterproofing can be created in conjunction with Schlüter-KERDI or KERDI-BOARD.

KERDI-BOARD vanity units have a flat surface and are resistant to warping, ageing and are highly stable, even when exposed to temperature or humidity on one side. They are ideal for a wide variety of applications. Substrates should be checked for sufficient stability and other project-related requirements.

The wall brackets are versatile and can be used in the bathroom, for example, as a practical solution for saving space and creating a tidy appearance. Wall-mounted KERDI-BOARD vanity units can also be used to construct barrier-free installations.

They are made of robust material and are extremely stable and durable.

Note:

After installation and covering with tiles or natural stone, the KERDI-BOARD-WW and -WS vanity units can bear a load of up to 50 kg in any installation variant.

The WASHBASIN triangular profiles are available in a wide variety of different finishes. Their suitability must be verified in applications exposed to chemical or mechanical stresses. The information provided below is intended as a general guideline.

WASHBASIN-S and -R profiles with TS coating (aluminium textured coating) feature surfaces with a natural appearance. The aluminium is suitably pre-treated and then powder coated with a polyurethane covering. The coating is colour-stable and UV and weather-resistant. Visible edges should be protected against abrasion and scratching.

The WASHBASIN-S and -R profiles, made of stainless steel V4A (material no. 1.4404 = AISI 316L) with a brushed surface, are ideal when high mechanical or specific chemical loads can be expected.

Even stainless steel of quality 1.4404 is not resistant to all chemical stresses, and may be affected by hydrochloric and hydrofluoric acid or certain chloride and brine concentrations, which may occur in cleaning agents or in swimming pools. Suitability for particular anticipated stresses should therefore be clarified in advance.