Schlüter-KERDI-BOARD, bonded over its entire surface

- The adhesive must bond with the substrate and mechanically join to the KERDI-BOARD anchoring fleece. For most substrates, a dry setting thin-bed mortar compliant with EN 12004 can be used. Otherwise, choose another suitable adhesive, but review any potential material incompatibilities beforehand.

- Apply thin-bed mortar with a notched trowel to either the substrate or the KERDI-BOARD.

- Fully embed Schlüter-KERDI-BOARD in the adhesive, creating a bond with the anchoring fleece. The curing time of the adhesive must be observed.

- The individual panels must be butted together and be aligned accordingly.

- Immediately after the KERDI-BOARD is affixed, tiles can be laid in the thin-bed method, using a dry-setting thin-bed mortar that meets the requirements of the selected covering. The notch size of the trowel must suit the tile format. Observe the curing time of the thin-bed mortar.

Schlüter-KERDI-BOARD affixed with spots of mortar

- Apply spots of mortar spaced roughly 30 cm apart onto Schlüter-KERDI-BOARD. Depending on the thickness of the layer, these spots may consist of a thin-bed mortar or a suitable bonding mortar.

- Position the panels on the wall, press them down and align them with a spirit level.

- As soon as the KERDI-BOARD is glued in place, tiling can begin using the thin-bed method, with a dry-setting thin-bed mortar suitable for the selected covering. The notch size of the trowel must suit the tile format. Observe the curing time of the thin-bed mortar.

Note: If a permanent bond between the spots of mortar and the substrate is not achieved, additional mechanical fastening is necessary with suitable anchors or screws.

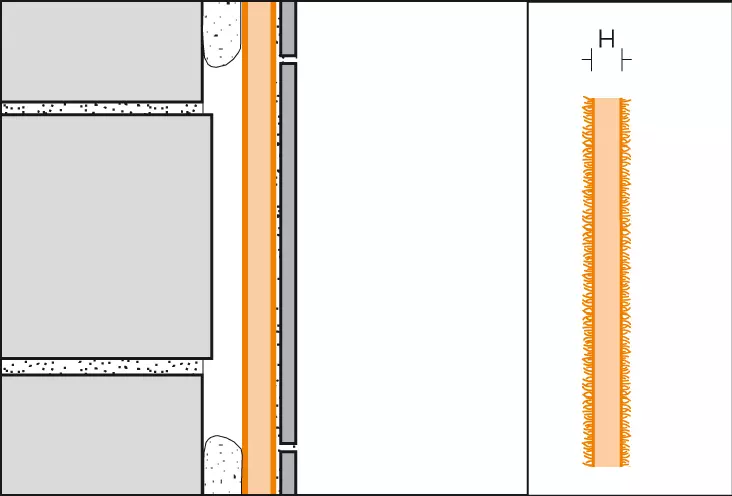

Schlüter-KERDI-BOARD on stud structures

- Schlüter-KERDI-BOARD can be attached either vertically or horizontally to correctly assembled stud structures. It should be secured with screws. If using support plates, the screws can be set into the abutting joint of the panels. Select the length of the screws such that they penetrate wooden stud structures by at least 20 mm and metal stud structures by at least 10 mm. The spacing between the screws should not exceed 25 cm. Depending on the installation requirements, the panel thickness for stud structures (centre line 62.5 cm) should be at least 19 mm.

- For vertical placement, fit the individual panels with closely abutting joints over the centre of the stud structure. In a horizontal installation, coat all vertically abutting joints that are not supported by a stud with tile adhesive, Schlüter-KERDI-FIX or Schlüter-KERDI-BOARD-ZDK double-sided adhesive tape. Where possible, such abutting joints should be arranged in an offset pattern.

Schlüter-KERDI-BOARD for partition walls

- The edge of a Schlüter-KERDI-BOARD panel is glued to a fixed wall such that at least the tile covering to be laid on the fixed wall integrates the KERDI-BOARD partition wall. Where possible, the partition wall should be inserted between the KERDI-BOARD panels of the fixed wall. Alternatively, the partition wall can be attached by first screwing a system-compatible angle or U-shaped profile to the fixed wall.

- Partition walls with an exposed end can be stabilised using a system-compatible U-shaped profile. If you wish to mount fittings to the U-shaped profile using screws, the flat plastic Schlüter-KERDI-BOARD-ZFP profile should be glued to the underside of the profile to provide better support for the screws. U-shaped profiles can also be used in floor and ceiling connections.

- All vertical and horizontal KERDI-BOARD joints must be sealed with thin-bed mortar or KERDI-FIX if applicable. If required for longer partition walls, a system-compatible angle or U-shaped profile can be affixed in one or more horizontal joints to provide stabilisation.

- Depending on the specific site requirements, such partition walls can be classified as lightweight wall panels without static verification. As a general rule, the panels should have a thickness of 50 mm. Panels used for shelf structures can have a thickness of 19 mm or more. This should also be determined on the basis of specific site requirements.

Pipe panelling in Schlüter-KERDI-BOARD

- The angle profiles and U-shaped elements in KERDI-BOARD allow you to cover pipework and electrical installations quickly and easily.

- The components, which are supplied flat, have V-shaped grooves and must first be cut to the required size. A single U-shaped element can also be cut into two angle elements with shorter anchoring legs.

- The elements are only folded together during installation, with an adhesive strip positioned in the V-shaped groove holding the element together.

- Glue the U-shaped or angled KERDI-BOARD elements to existing walls with the edges of the panel. A thin-bed mortar or KERDI-FIX is suitable for this. If necessary, start by fastening the Schlüter-KERDI-BOARD-ZW angle profile at the wall for stable attachment.

Note: KERDI-BOARD as bonded waterproofing, see the Waterproofing section.

Rounded walls made with Schlüter-KERDI-BOARD

- Grooved Schlüter-KERDI-BOARD panels are suitable for creating rounded and curved structures.

- The grooved panels are first cut to the required size. If you need larger panels, you can simply join multiple boards together at their edges using double-sided tape.

- If the grooves face inward, they should be filled with tile adhesive in advance.

- Outward-facing grooves should be filled with thin-bed mortar before or during tiling.

Note: KERDI-BOARD as bonded waterproofing, see the Waterproofing section.

Schlüter-KERDI-BOARD in floors

- Schlüter-KERDI-BOARD is suited for creating flat substrates for floors, for example when renovating sanitary installations used by foot traffic or similar spaces.

- To accommodate KERDI-BOARD in thicknesses of 5, 9, 12.5 or 19 mm, the substrate must be free of any items that may inhibit bonding, sufficiently load bearing, and level. Any necessary levelling work should be completed before installing KERDI-BOARD.

- The adhesive must bond with the substrate and mechanically join to the KERDI-BOARD anchoring fleece. For most substrates, a dry setting thin-bed mortar compliant with EN 12004 can be used. Otherwise, choose another suitable adhesive, but review any potential material incompatibilities beforehand.

- Apply thin-bed mortar to the substrate with a notched trowel and fully embed the Schlüter-KERDI-BOARD in the adhesive so that a bond is formed with the anchoring fleece. The individual panels must be butted together and be aligned accordingly. The curing time of the adhesive must be observed.

- If the substrate is sufficiently load-bearing, KERDI-BOARD with a thickness of 28 mm or more can also be fitted and height-aligned over spots of thin-bed mortar or other mortar types. The spots of mortar must be placed sufficiently close together to achieve the required load-bearing capacity. Apply thin-bed mortar over the joints at the panel edges, ensuring that the joints overlap the mortar spots.

- Prevent any build-up of tension in the KERDI-BOARD or the tile covering in the edge areas, for example by using an edge strip.

- Immediately after fully affixing the KERDI-BOARD, the tiles (minimum size 5 x 5 cm) can be laid in the thin-bed method, using a thin-bed mortar that meets the requirements of the selected covering. If using spots of mortar, allow these to cure until they are sufficiently load-bearing. The notch size of the trowel must suit the tile format. Observe the curing time of the thin-bed mortar.

- When installing movement joints for perimeter, edge and connection joints, be sure to comply with the technical regulations.

Waterproofing with Schlüter-KERDI-BOARD

Schlüter-KERDI-BOARD can be installed in accordance with the waterproofing standard DIN 18534 applicable in Germany. Water exposure classes: W0-I to W3-I*. In addition, Schlüter-KERDI-BOARD has been given the national technical approval (abP) required in Germany.

Moisture load class as specified by ZDB: 0 to B0, and A and C.

KERDI-BOARD features European Technical Approval (ETA) pursuant to ETAG 022 (watertight covering kits) and bears a CE mark. Where work must be CE-compliant or in accordance with the certificate of technical approval (abP), only system-certified thin-bed mortar should be used.

* With abP and/or based on ETA for ETAG 022. Our Technical Department will be pleased to provide further information on use and installation on request.

We recommend the use of our waterproofing membrane Schlüter-KERDI (see product data sheet 8.1 Schlüter-KERDI) for load class B, "containers", (e.g. for swimming pools).

Panel joints in the surface and corner areas of the KERDI-BOARD must be fully embedded with Schlüter-KERDI-KEBA sealing tape, min. width 12.5 cm, using Schlüter-KERDI-COLL-L sealing adhesive. The sealing tape must have an overlap of at least 5 cm.

KERDI-KEBA can also be used to create functionally effective joints to fixed structural components such as door and window frames made of metal, wood or plastic. To do this, apply KERDI-FIX to the bonding surface of the structural component and KERDI-COLL-L to the surface of the KERDI-BOARD and fully cover the entire joint area with sealing tape.

The suitability of KERDI-FIX for the structural element material must be verified in advance. The practicability of the joints should be evaluated depending on the site conditions and should be performed with great care.

Cut the KERDI-BOARD at any movement joints or expansion joints and glue over the abutting joints with Schlüter-KERDI-FLEX. KERDI-FLEX should also be used for flexible edge finishes.

Rendered and plastered layers on Schlüter-KERDI-BOARD

KERDI-BOARD is also a suitable substrate for rendered and plaster surfaces. Such surfaces may adjoin tiled areas (e.g. half-height tiling) or be entire wall surfaces in other areas.

The abutting joints in the surface and at external and internal corners, and also exposed edges, must be reinforced and covered with filling mortar. Our self-adhesive KERDI-BOARD-ZSA joint reinforcement tape can be used for this purpose.