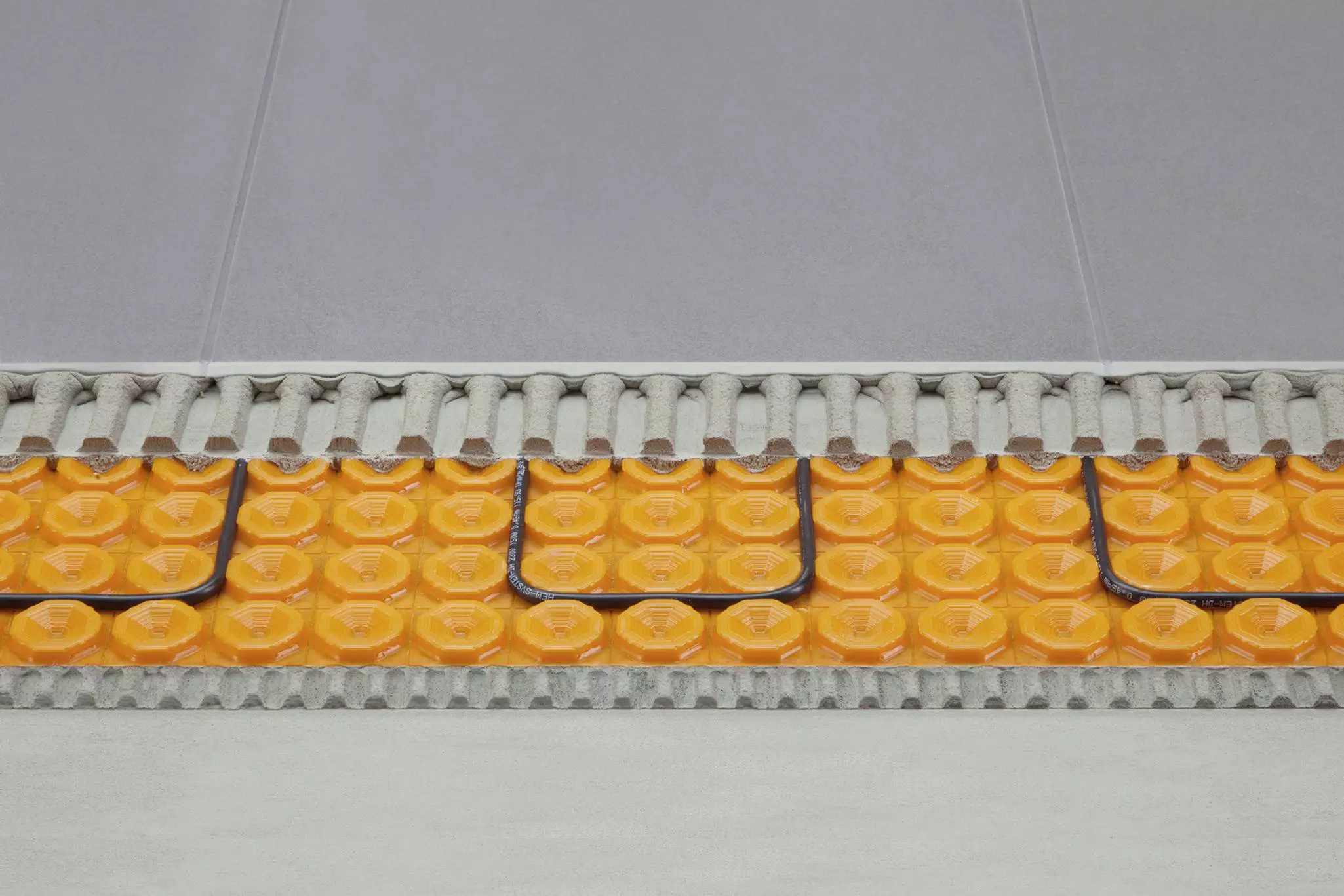

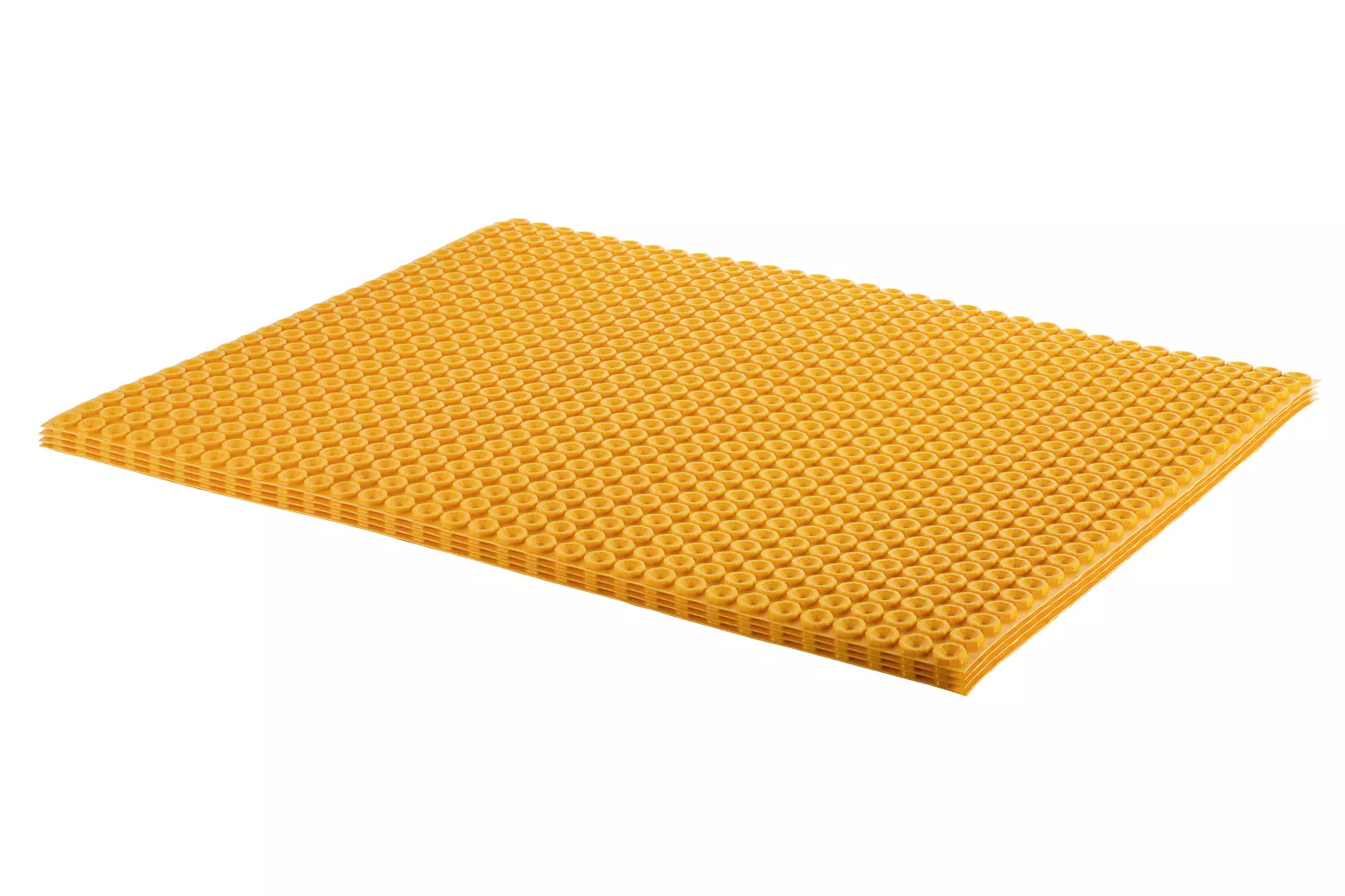

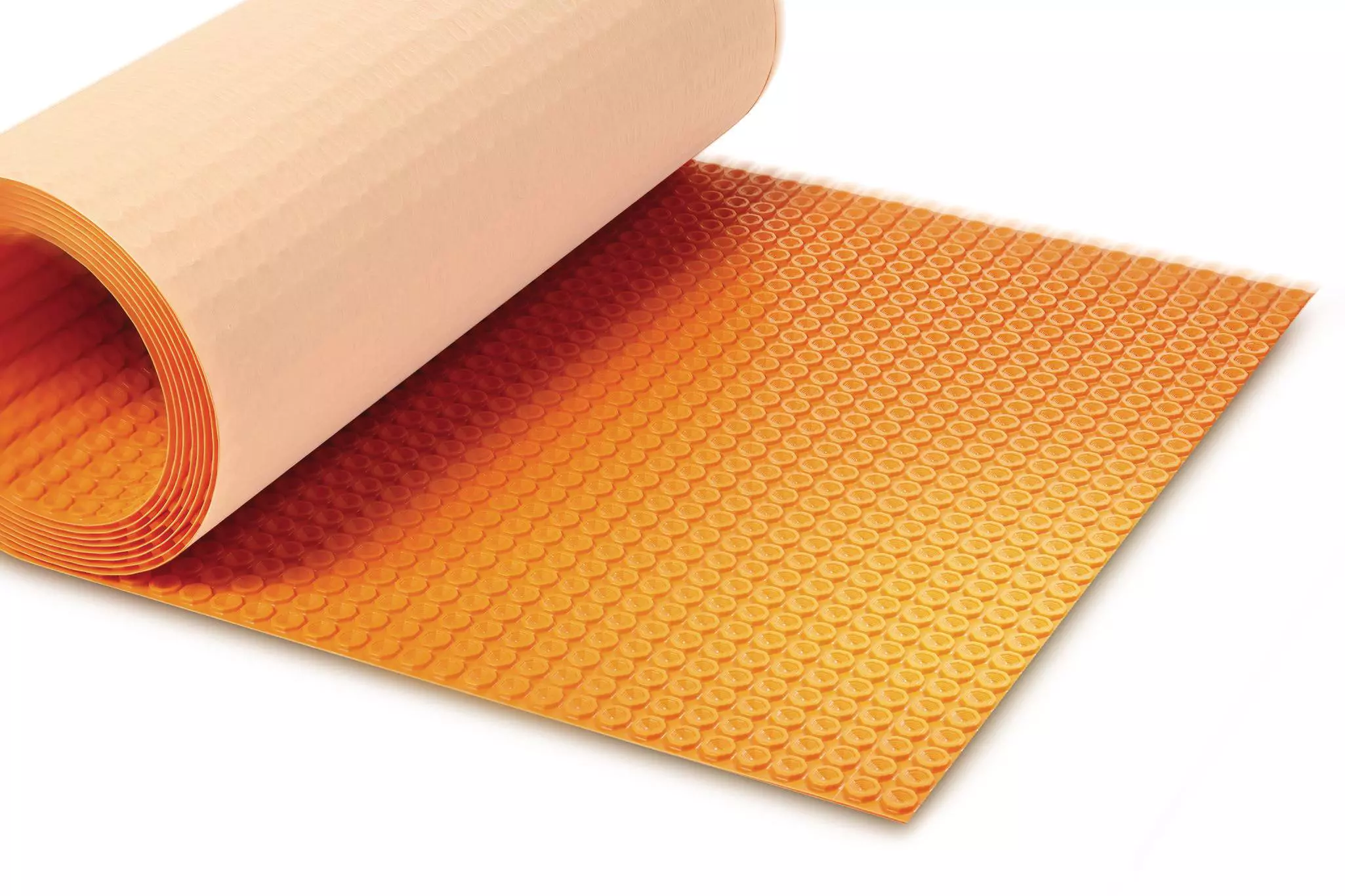

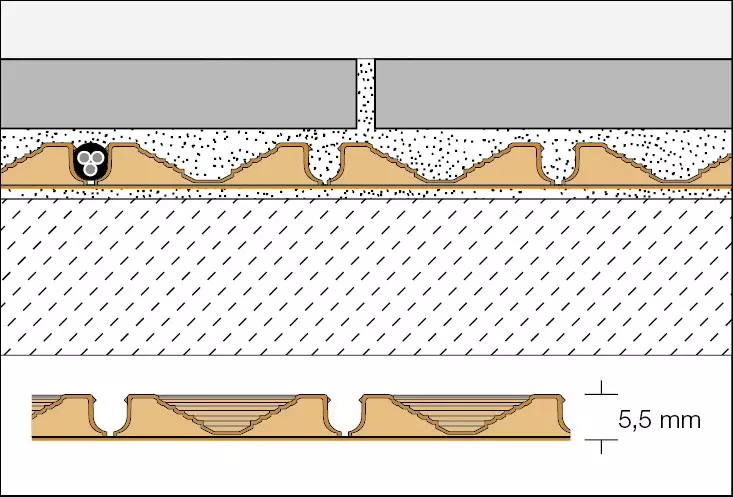

Schlüter-DITRA-HEAT is a polypropylene membrane with a cut back stud structure and an anchoring fleece laminated on the underside.

It is a universal substrate for tile coverings that forms an uncoupling, waterproofing and vapour pressure equalisation layer and can also be used to attach heating cables.

The substrate for the installation of DITRA-HEAT must be level and load bearing. DITRA-HEAT is installed in thin-bed tile adhesive that is suitable for the substrate, using a notched trowel (recommended size: 6 x 6 mm). The anchoring fleece on the underside of DITRA-HEAT is fully embedded and the fabric bonds with the adhesive. The curing time of the adhesive must be observed.

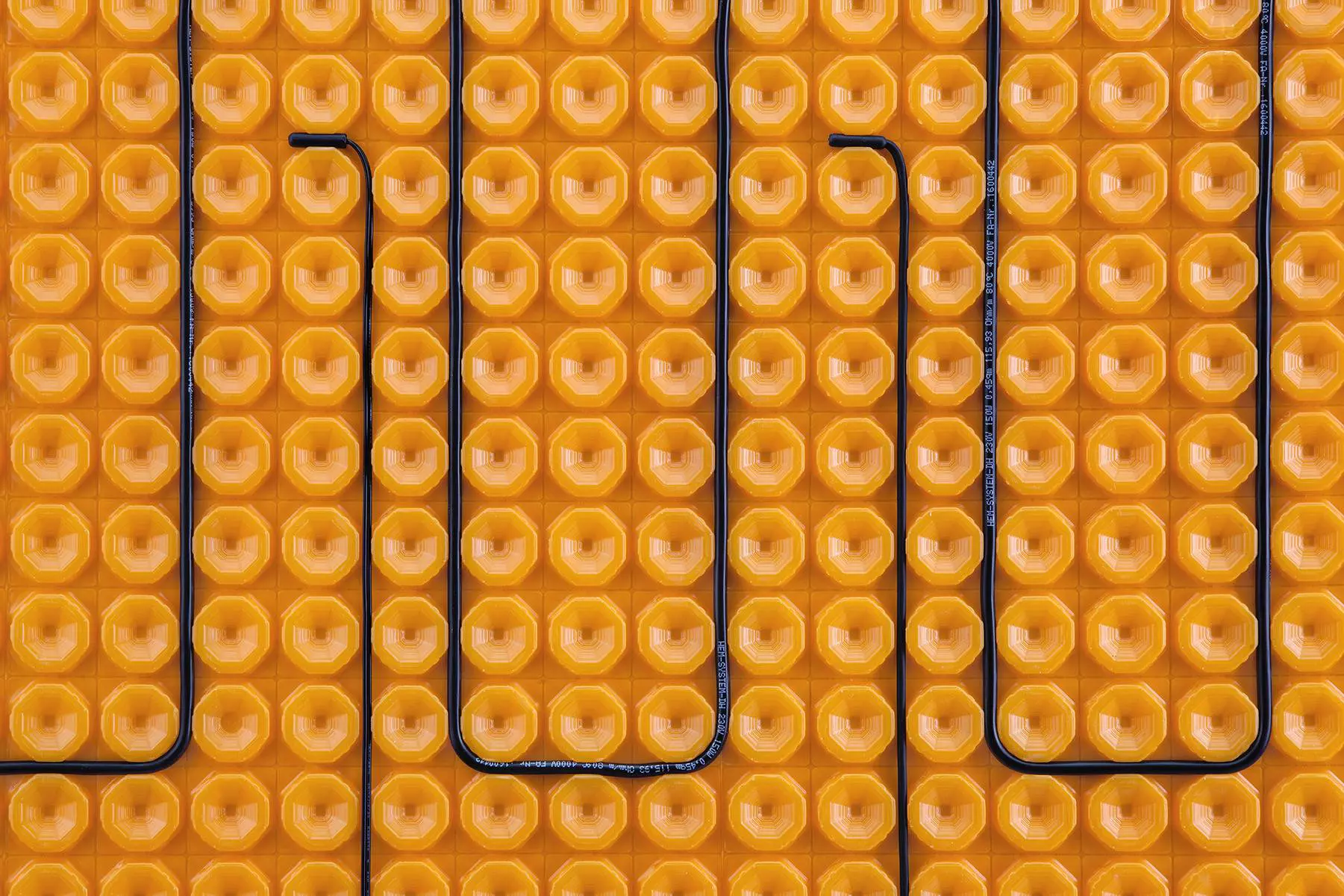

In floor areas, the heating cables can be installed immediately after adhering DITRA-HEAT, using a minimum spacing of 9 cm (every 3rd stud).

For wall installation, the heating cables are installed once an adequate adhesive bond has been reached. The installation spacing is either 6 cm (every 2nd stud) or 9 cm (every 3rd stud) (for more information, see data sheet 6.4 on page 7, see Downloads).

The use of mats is recommended for wall assemblies.

The tiles are installed directly over DITRA-HEAT in accordance with the applicable regulations, using the thin-bed method. The thin-bed tile adhesive bonds with the cut-back stud structure of the DITRA-HEAT membrane.

DITRA-HEAT is waterproof and resistant to any chemical stresses that typically occur in conjunction with tiled coverings. Where required, DITRA-HEAT can be used to create a certified bonded waterproofing assembly.

Summary of functions:

a) Uncoupling

DITRA-HEAT uncouples the covering from the substrate and neutralises stresses between the substrate and the tile covering that result from various deformations. The material also bridge tension cracks from the substrate and prevent them from affecting the tile covering.

b) Waterproofing

DITRA-HEAT is a waterproof polypropylene membrane with a relatively high water vapour diffusion seal. With properly installed abutting joints and carefully sealed transitions to walls and structural elements, DITRA-HEAT can be used to create a certified bonded waterproofing assembly with the tile covering.

DITRA-HEAT can be installed in accordance with the waterproofing standard DIN 18534 applicable in Germany. Water exposure classes: W0-I to W3-I*. DITRA-HEAT also features the national technical approval (abP) required in Germany.

Moisture load class according to ZDB: 0 to B0, as well as A.

Schlüter-DITRA-HEAT / -HEAT-DUO has a European Technical Assessment (ETA) in accordance with EAD 030436-00-0503, a certificate of technical approval for the German market (abP) and bears a CE mark.

Where work must be CE-compliant or in accordance with the certificate of technical approval (abP), only system-certified thin-bed mortar should be used. For further information about thin-bed mortars and the corresponding technical approval certificates, please contact us at the address provided on this data sheet.

The waterproofing system DITRA-HEAT/ -HEAT-DUO effectively protects the sub-structure from damage caused by permeating moisture or aggressive substances.

* With abP and/or based on ETA as per EAD 030436-00-0503. Further information on use and installation is available on request from our Technical Department.

c) Load distribution (load induction)

Tiles installed over DITRA-HEAT in floor areas should have a minimum size of 5 x 5 cm and a thickness of at least 5.5 mm. DITRA-HEAT transfers mechanical stresses impacting the tile covering directly into the substrate via the bottom of the recesses, which are filled with thin-bed mortar. That makes tile coverings installed on DITRA-HEAT especially durable. The tiles for the corresponding application area must be sufficiently thick and have adequate compressive stability to withstand high traffic loads (e.g. in commercial areas) or large point loads (such as concert pianos, forklifts or shelf systems). The information and tile thicknesses specified in the ZDB information sheet "Ceramic floor coverings with high mechanical stress resistance", valid in Germany, must be observed.

Tiles in high-stress areas must be wholly embedded in the tile adhesive.

The impact of hard objects should be avoided on ceramic coverings. The tile dimensions should be at least 5 x 5 cm.

d) Bonded assembly

Based on the fleece fabric bond in the thin-bed mortar on the substrate, and through mechanical anchoring of the thin-bed mortar in the undercut stud structure, DITRA-HEAT creates a strong bond between the tile assembly and the substrate. This makes DITRA-HEAT suitable for wall and floor installation.

Substrates for Schlüter-DITRA-HEAT

Always check that the substrates on which DITRA-HEAT is to be installed are level, load bearing, clean and compatible with the materials to be used. Remove any surface components that could weaken the bond. Any levelling, height adjustment or slope compensation must be carried out before installing DITRA-HEAT.

To guarantee effective floor heating, heat insulation is required, especially for installations adjoining soil or unheated spaces.

For a faster heat-up response on unheated screed assemblies, we recommend using DITRA-HEAT-DUO for its thermal separation function or Schlüter-KERDI-BOARD as an insulation layer (see data sheet 12.1).

Concrete

Concrete is prone to long-term structural deformation due to shrinkage. In addition, deflection in concrete and pre-stressed concrete can cause tensions to occur.

Since DITRA-HEAT absorbs the resulting stresses between the concrete and the tile covering, tiles can be immediately installed as soon as the concrete is ready to bear weight.

Cement screeds

In accordance with the applicable regulations, cement screeds must have cured for a minimum of 28 days prior to tile installation and have a moisture content below 2 CM %.

Floating and heated screeds have a particular tendency to buckle and crack even later, e.g. due to mechanical stresses and temperature fluctuations. With DITRA-HEAT, tiles can be installed on green cement screeds as soon as they are ready to bear weight.

DITRA-HEAT will neutralise cracks and screed deformations developing later and will prevent them from affecting the tile covering.

Gypsum based screeds

Under the applicable regulations, calcium sulphate (anhydrite) screeds may have a maximum residual moisture level of 0.5 CM% at the time of tile laying. In contrast, tile installation is permissible from a residual moisture level of 2 CM % with DITRA-HEAT.

If necessary, the screed surface should be treated (grinding, priming) as specified by the technical regulations and manufacturer instructions. DITRA-HEAT can be installed with dry-setting or other suitable thin-bed tile adhesives. DITRA-HEAT protects the screed surface against permeating moisture. Because gypsum based screeds are susceptible to moisture, screeds must be protected against humidity, e.g. moisture seepage on the underside.

Heated screeds

DITRA-HEAT can be used on heated screeds, provided the above notes (cement, gypsum based screeds) are followed. Covering assemblies created with DITRA-HEAT are ready for heating only 7 days after completion. Starting from a temperature of 25 degrees C, the supply temperature can be increased by no more than 5 degrees C a day to a maximum of 40 degrees C.

Note: Installing DITRA-HEAT over heated screeds makes it possible to operate an individual, partial heating system that is independent of the central heating system. This allows for completely turning off the central heating system during seasonal transition times.

DITRA-HEAT assemblies can also cover peak loads.

(Due to the thermal separation properties of the product, DITRA-HEAT-DUO should not be installed over heated screeds.)

Vinyl coverings and coatings

All surfaces must be load bearing and pre-treated or suitable for bonding with an appropriate adhesive, in which the DITRA-HEAT anchoring fleece can be embedded. The compatibility of the adhesive with the substrate and with DITRA-HEAT must be verified in advance.

Chipboard and compressed wood panels

These materials undergo significant deformation based on the influence of moisture (or through fluctuations in humidity). Therefore, chipboard and compressed wood panels with special water-repellent treatment to protect against moisture must be used.

These panels can generally be used as a substrate for floors and walls in interior spaces.

However, they have to be thick enough to be sufficiently stable in conjunction with a suitable support assembly.

They should be secured with screws placed suitably close together. Joints should be of a tongue-and-groove type and must be bonded with adhesive. Edge joints of about 10 mm should be maintained to adjacent structural elements.

DITRA-HEAT neutralises any tensions with the tile covering and also prevents permeating moisture.

Hardwood floors

In principle, ceramic coverings can be installed on sufficiently weight bearing hardwood floors with tongue and groove connections. The wooden substrate should have balanced moisture levels before DITRA-HEAT can be installed.

It has proven beneficial here to lay an additional layer of chipboard or compressed wood panels. Uneven floor surfaces should be levelled with suitable measures beforehand.

Masonry or mixed substrates

Masonry structures built with bricks, sand lime bricks, cement blocks, aerated concrete or similar materials are generally a suitable substrate for DITRA-HEAT. The substrate must be levelled in advance.

In restoration and remodeling projects, substrates frequently consist of different materials (mixed masonry), which have a tendency to crack at the interfaces with other materials due to different deformation rates. DITRA-HEAT protects the tile covering from the resulting tensions and cracks.

Gypsum plaster and bricks

Gypsum substrates should be completely dry in accordance with the relevant regulations. The surfaces may need to be pre-treated with a primer. DITRA-HEAT can be installed with dry-setting or other suitable thin-bed tile adhesives.