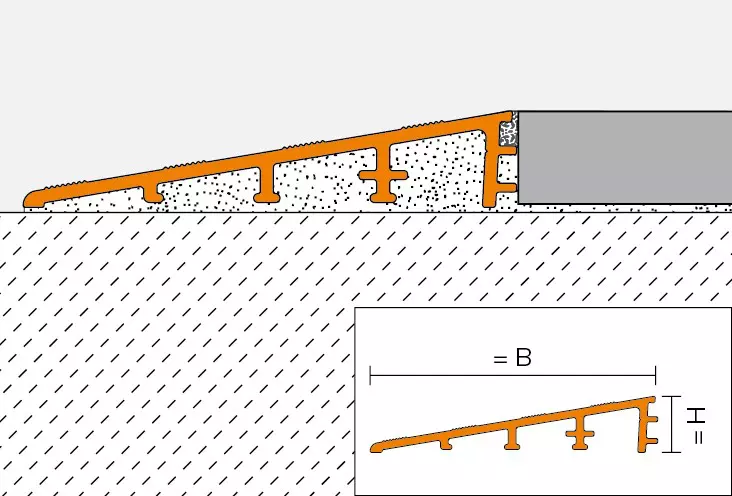

Schlüter-RENO-RAMP and -RAMP-K are available in the following material version:

Material properties and areas of application

In special cases, the suitability of a proposed type of profile must be verified, based on anticipated chemical, mechanical, and/or other stresses.

Schlüter-RENO-MU are profiles made of brass. Minor manufacturing flaws are unavoidable on their untreated surfaces. They are suitable for absorbing high mechanical stresses. Brass is resistant to most chemicals used in tiled environments.

Brass that is exposed to air will oxidise, resulting in a natural patina. Exposure to moisture or aggressive substances can reinforce the oxidation, resulting in stains on the profile surface.

Schlüter-RENO-AU are profiles made of aluminium. Technically, these are so-called semi-finished products, in which minor manufacturing traces also cannot be avoided. The suitability of the profiles should be reviewed based on the anticipated chemical stresses. Aluminium is sensitive to alkaline media.

Cementitious materials, in conjunction with moisture, become alkaline, which may result in corrosion depending on the concentration and length of exposure (aluminium hydroxide formation). Any adhesive, mortar or grout must therefore be removed from visual areas immediately. Solidly embed the profile in the setting material to prevent alkaline water from accumulating in small cavities.

In case of more demanding visual requirements, Schlüter-RENO-AEU or -EBU with post-treated, high-quality finishes are available.

Schlüter-RENO-AEU/-RAMP profiles made of anodised aluminium have an anodised finish that retains a uniform appearance during normal use. The finish may be damaged by aggressive substances or abrasive stresses. Tile adhesive, mortar and grout can scratch the surface of the profile; therefore, any residue must be removed immediately. Otherwise, the description regarding aluminium applies.

Schlüter-RENO-EU/-EBU are made of stainless steel 1.4301 (V2A) and are particularly well suited for applications that, in addition to heavy mechanical stresses, require resistance to chemicals such as acidic or alkaline detergents.

Even stainless steel is not resistant to all chemical stresses.

Substances such as hydrochloric or hydrofluoric acid or certain chloride and brine concentrations may cause damage. In certain cases, this also applies to seawater pools. Special anticipated stresses should therefore be verified in advance.