V2A, material no. 1.4301 = AISI 304

V4A, material no. 1.4404 = AISI 316L

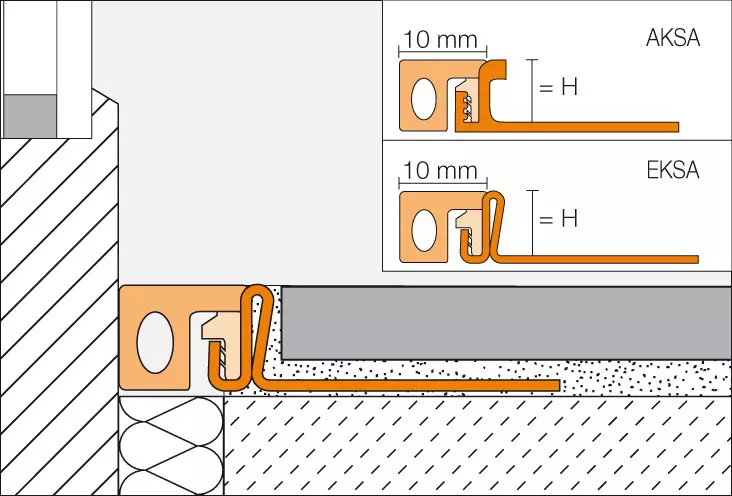

The movement zone consists of highly flexible thermoplastic rubber with inserts made of a harder material.

Material properties and areas of application

The suitability of the selected profile type must be verified based on the anticipated chemical, mechanical, and/or other stresses.

The support profiles of Schlüter-DILEX-EKSB are made of stainless steel 1.4301 (V2A). The support profiles of DILEX-EKSN and -EKSA are made of stainless steel 1.4301 (V2A) or 1.4404 (V4A). Stainless steel is particularly well suited for applications that, in addition to heavy mechanical stresses, require resistance to chemicals such acidic or alkaline media, detergents or de-icing salts. Depending on the anticipated stresses, you can choose between the alloy materials 1.4301 (V2A) or 1.4404 (V4A). The use of V4A is recommended if consistent exposure is expected, for example in the case of swimming pools (fresh water).

Even stainless steel of quality 1.4404 is not resistant to all chemical stresses such as hydrochloric and hydrofluoric acid or certain chloride and brine concentrations. In certain cases, this also applies to seawater pools. Any particular stresses anticipated should therefore always be clarified in advance.

Schlüter-DILEX-AKSN and -AKSA with lateral anchoring leg profiles of aluminium are sensitive to alkaline media.

Cementitious materials, in conjunction with moisture become alkaline. Since aluminium is sensitive to alkaline substances exposure to the alkali (depending on the concentration and duration of exposure) may result in corrosion (aluminium hydroxide formation).

For this reason, remove mortar or grouting material immediately from all visible areas and do not cover freshly installed coverings until the adhesive and grout have dried. Solidly embed the profile in the setting material to prevent alkaline water from accumulating in small cavities.

The movement zones of all DILEX-KS and -KSA profile types consist of highly flexible thermoplastic rubber. This material is UV-resistant, suitable for outdoor use, and resistant to the chemical stresses typically associated with tile coverings and has been specially treated to resist fungi and bacteria.

The insert is resistant to temperatures ranging from -60 °C to +100 °C. The synthetic rubber can be heat bonded to extend the profile length.

The tile inserts DILEX-KS/K are available in all colours for cross joints created with the movement profiles DILEX-KS.