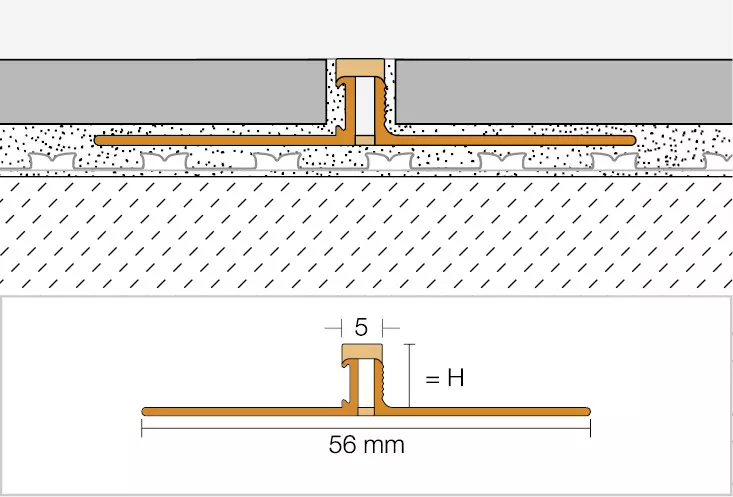

Schlüter-DILEX-BWS is a pre-fabricated plastic movement joint profile for installation in tiled coverings. The perforated anchoring legs, made of recycled rigid PVC, are secured in the tile adhesive beneath the tiles where they transmit occurring movements to the movement zone (the upper movement zone is also the visible surface).

The movement zone absorbs compressive, tensile, and shear stresses. The soft CPE movement zone and visible surface is only 5 mm wide, matching common grout joint widths.

Consequently, the smaller width absorbs relatively limited movements; this should be taken into account when evaluating the requirements for a specific application. DILEX-BWS is particularly suited as a movement joint for tile coverings installed over Schlüter-DITRA.

If larger movements within the covering are anticipated, installation of Schlüter-DILEX-BWB, with a 10 mm movement zone, is recommended.

In addition to residential applications, DILEX-BWS can also be installed in areas with moderate traffic loads, such as offices or salesrooms. The profile is also suited for exterior use.