Schlüter-KERDI-BOARD is a multi-purpose tile substrate for wall areas, that can also function as a bonded waterproofing assembly in conjunction with tile or natural stone coverings. This versatile panel can be used in many applications.

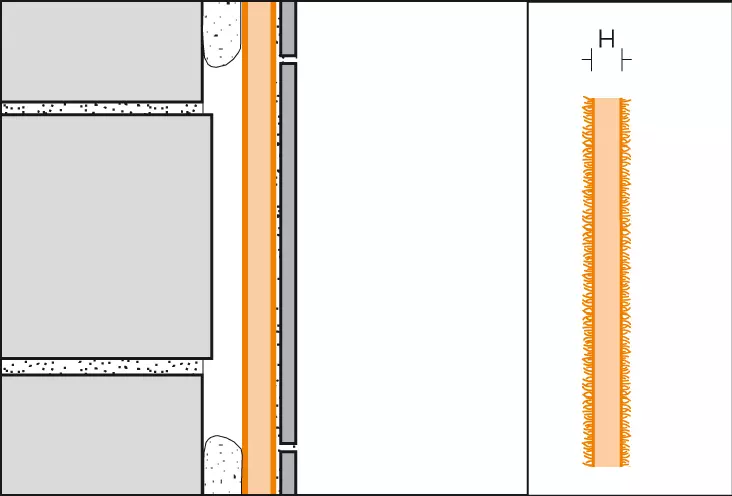

The panel consists of an extruded rigid foam, laminated on both sides with a special reinforcement material and a fleece fabric to facilitate anchoring in the tile adhesive.

Available in thicknesses of 5, 9, 12.5, 19, 28, 38 and 50 mm, KERDI-BOARD covers a broad range of application areas in which a level, waterproof substrate is required for tile or natural stone coverings.

Schlüter-KERDI-BOARD is waterproof and resistant to any chemical stresses that typically occur in conjunction with tiled coverings. Where necessary, KERDI-BOARD can be used to provide certified bonded waterproofing.

So long as the seams and connection areas are properly installed, the backerboard can be used to provide certified bonded waterproofing.

KERDI-BOARD can be used to create tiling substrates on existing carcass masonry, on existing floor substrates of any kind, on stud structures in wood or metal, and for creating standalone straight or rounded partition walls, for cladding over prewall installations or pipes (pipe boxes), for panelling for straight or rounded tubs and showers, for creating kitchen countertops, vanity units, shelving or any other bathroom structures. It is equally suited to creating level substrates for floors when renovating sanitary installations with foot traffic and similar areas.

KERDI-BOARD is easy to cut to size with a utility knife. The product features printed gridlines on the top side for quick and neat installation.

KERDI-BOARD can be glued over its entire surface in wall areas or affixed on spots of thin-bed mortar or other suitable adhesive/mortar. If required, the board can be further anchored using dowels. The product is attached to wood or metal stud structures using the fastening screws included in the product range.

Tiles are laid directly onto KERDI-BOARD, using the thin bed method.

Other suitable rendering materials or plaster layers of a trowelling consistency can also be applied.