Schlüter-DILEX-EMP is a maintenance free stainless steel movement joint profile for absorbing horizontal movements. It is suitable for ceramic tile and natural stone coverings installed in mortar beds that are subjected to high mechanical stresses.

DILEX-EMP offers secure edge protection for coverings used by conveyor vehicles and is, therefore, suited for use in warehouses, production facilities, shopping centres and car parks, or for floor surfaces maintained with cleaning machines.

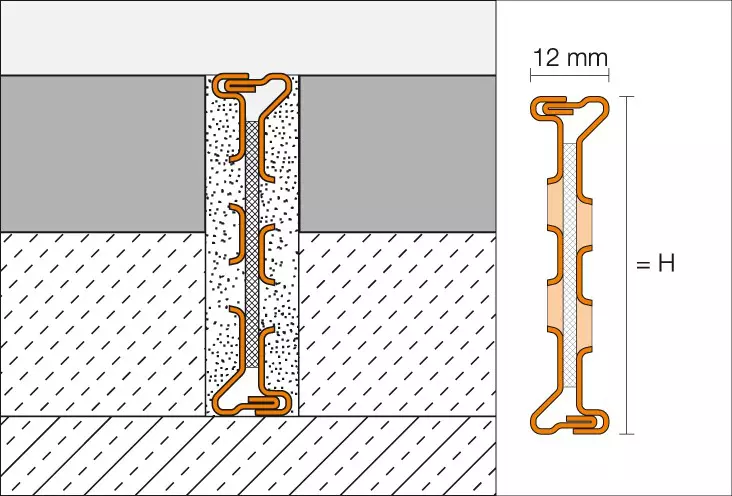

The profile system is suitable for creating expansion joints in floor coverings made of ceramic tile, natural stone, brick or agglomerate pavers over screed mortar beds. It absorbs the movements of the covering assembly with its flexible tongue and groove connection. However, the profile is not designed to absorb shear stresses. In its base position, DILEX-EMP has a visible surface in a width of 12 mm.