RONDEC-A is available in the following materials:

- AE = anodised aluminium

- AK = matte copper/bronze anodised aluminium

- AM = matte brass anodised aluminium

- AT = matte titanium anodised aluminium

- ACG = polished chrome anodised aluminium

- AKG = polished copper/bronze anodised aluminium

- AMG = polished brass anodised aluminium

- ATG = polished titanium anodised aluminium

- ACGB = brushed chrome anodised aluminium

- AGSB = brushed graphite black aluminium

- AKGB = brushed copper/bronze anodised aluminium

- AMGB = brushed brass anodised aluminium

- ATGB = brushed titanium anodised aluminium

Material properties and areas of application

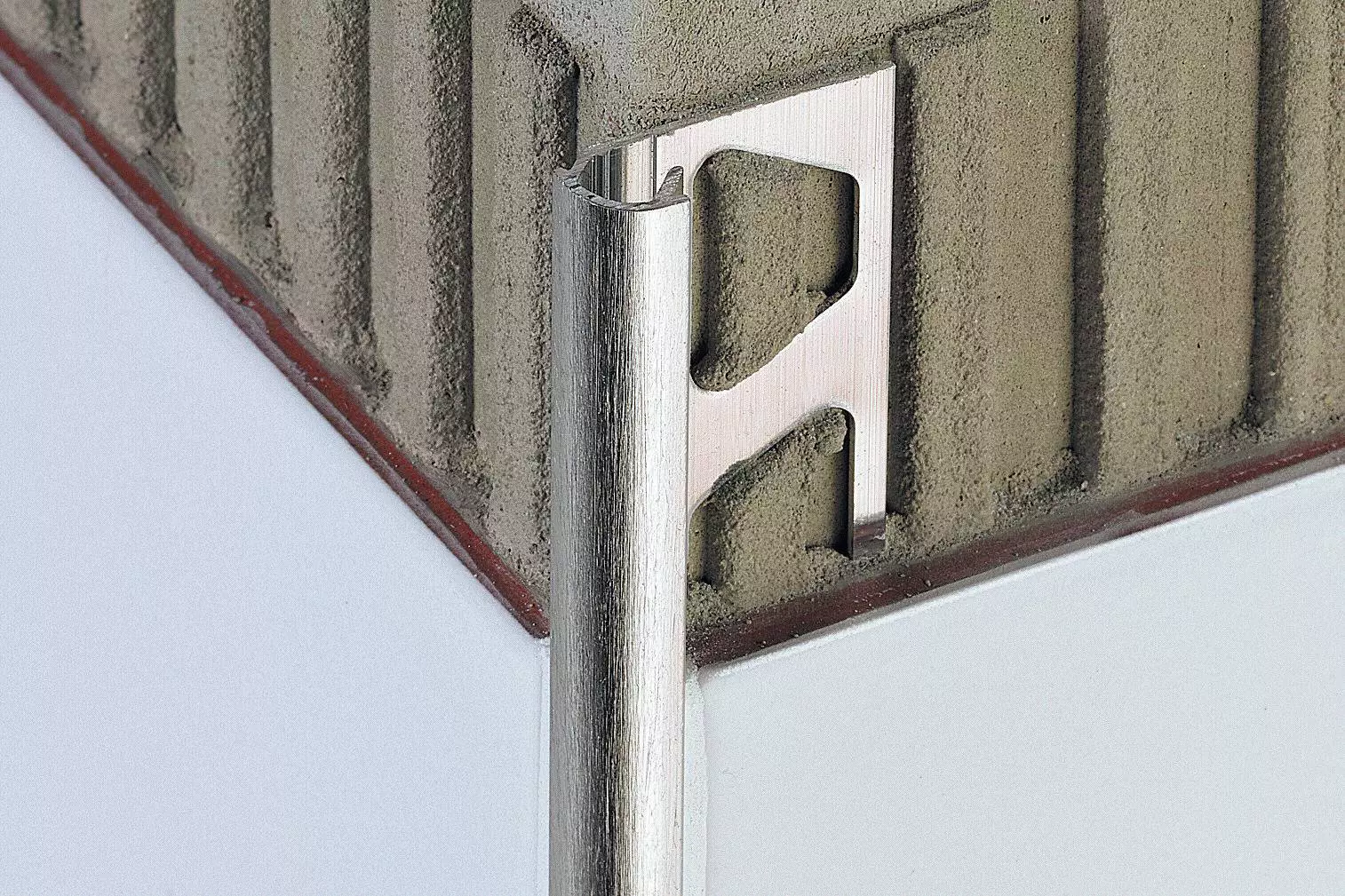

Schlüter-RONDEC is available in a wide variety of materials and finishes.

In applications exposed to chemical or mechanical stresses, the profile’s suitability must be verified. The information provided below is intended as a general guideline.

Schlüter-RONDEC-A (anodised aluminium): The aluminium features an anodised finish that retains a uniform appearance during normal use. Surface areas must be protected against abrasion or scratching. Aluminium is sensitive to alkaline media. Cementitious materials, in conjunction with moisture, become alkaline. Since aluminium is sensitive to alkaline substances, exposure to the alkali (depending on the concentration and duration of exposure) may result in corrosion (aluminium hydroxide formation). Remove adhesive or grout immediately from visible areas and don't cover freshly installed assemblies with a protective foil. In addition, ensure that the profile is solidly embedded in the setting material to prevent water from accumulating in small cavities.

Note: Due to different manufacturing processes, slight colour discrepancies between the profiles and the corners may occur.