1. The substrate must be properly waterproofed in advance, using a suitable bonded waterproofing system of Schlüter. Any required levelling work, e.g. a threshold in the door transition area, must be installed prior to waterproofing.

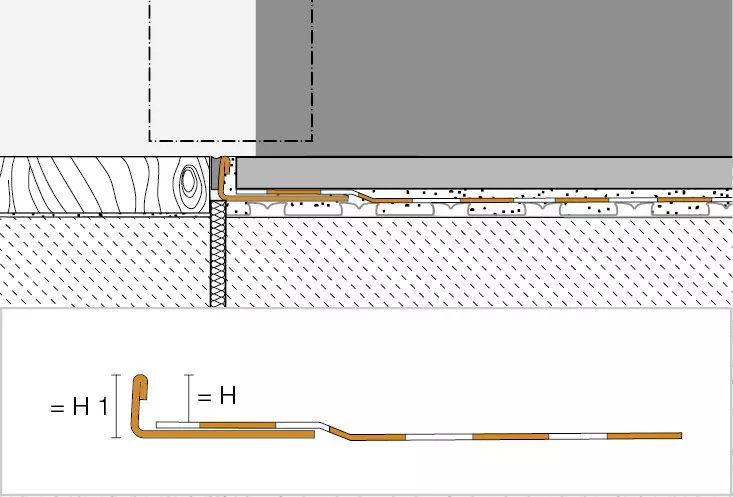

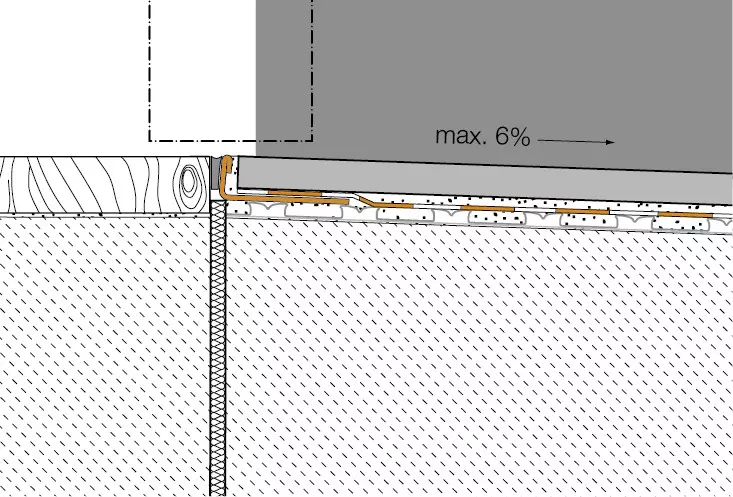

2. Select the profile height (H = inside height above the sealing band) according to the tile thickness and the installation method.

3. Cut the profile to the desired length. It is best to make an incision in the sealing band with a sharp utility knife approx. 2 mm from the actual cutting edge and to then cut the profile to size with an angle grinder or a handsaw.

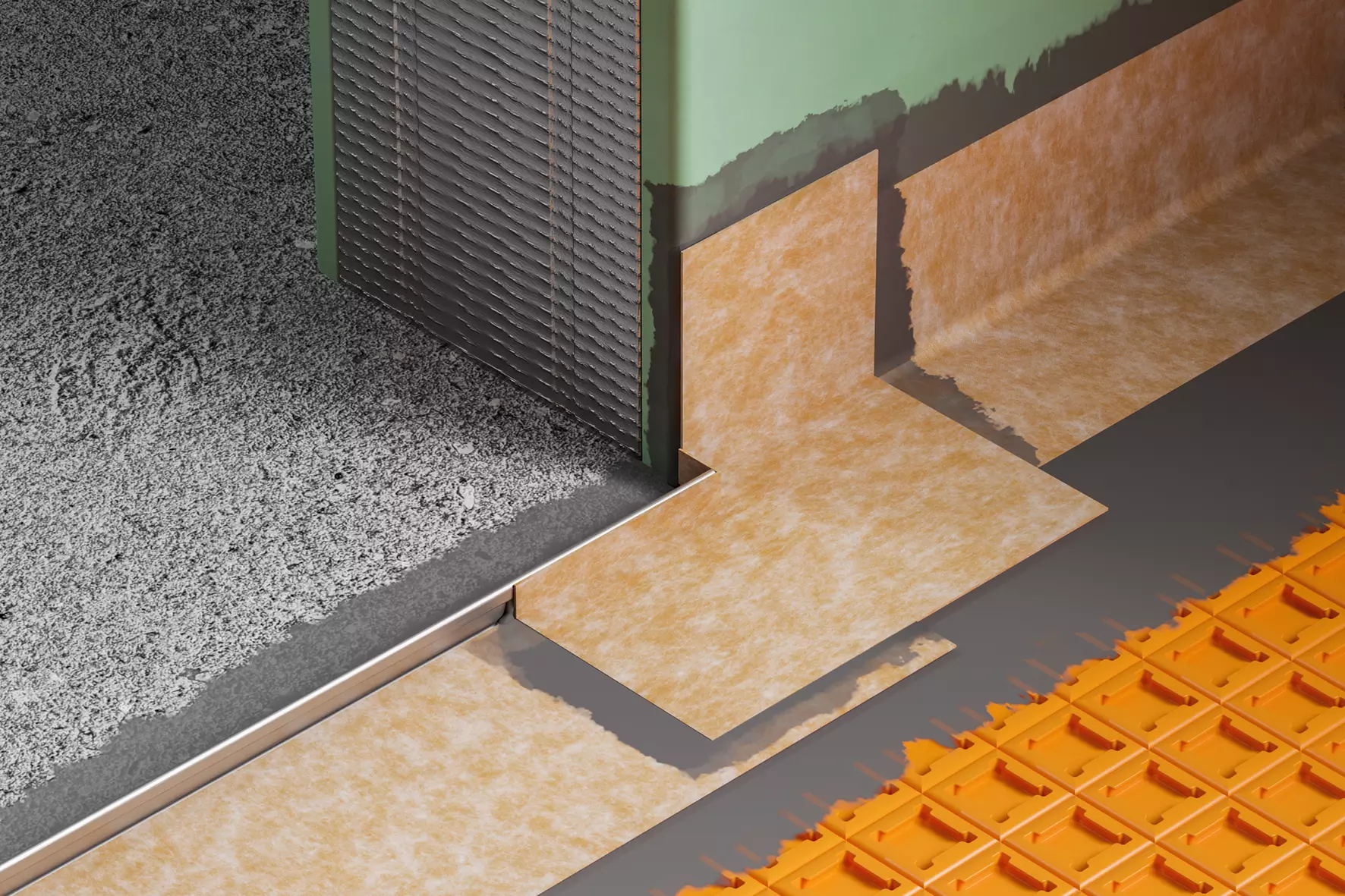

4. Apply Schlüter-KERDI-COLL-L on the waterproofing surface in the place where the capillary break is to be installed. Fully embed the profile and the sealing band in the fresh sealing adhesive and align them.

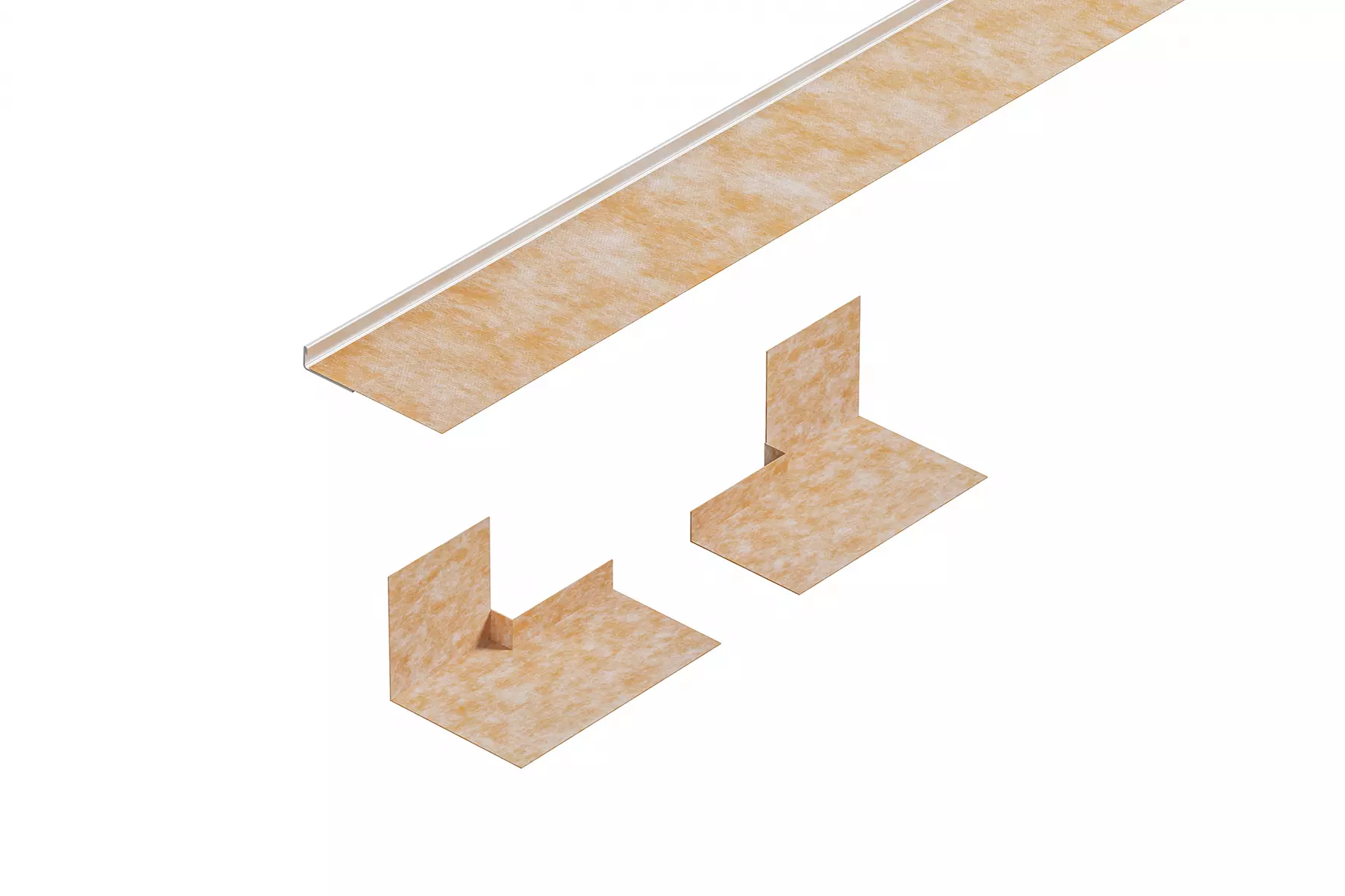

5. Use the prefabricated KERDI corners to create connections to adjoining structural elements. Cut the corners to match the profile height before applying adhesive.

6. The corners can be fully embedded on the waterproofing assembly and on the stainless steel profile with either KERDI COLL-L or KERDI-FIX.

7. The covering can be installed as soon as the bonded waterproofing assembly is tightly sealed at all overlaps, corners and joints. No curing time is required.

8. To install the tiles, apply dry setting thin-bed tile adhesive directly on the waterproofing membrane. Embed the adjoining tiles as much as possible and align them in such a way that the upper lip of the profile is flush with the tile. Note: The profile may slightly protrude or be recessed in the wall area to offset dimensional variations in the covering material. The profile should not protrude over the surface of the covering; preferably, it should be approx. 1 mm below the top level of the covering.

9. Leave a joint of approx. 1.5 mm between the adjoining tile and the profile.

10. Completely fill the space between the tile and the profile with grout.

11. Completely fill the space between the profile and the adjoining floor covering with an elastic filler compound.