Schlüter-KERDI-LINE-VARIO is a flexible, multi-piece, linear drainage system for creating floor level showers with ceramic tiles or natural stone.

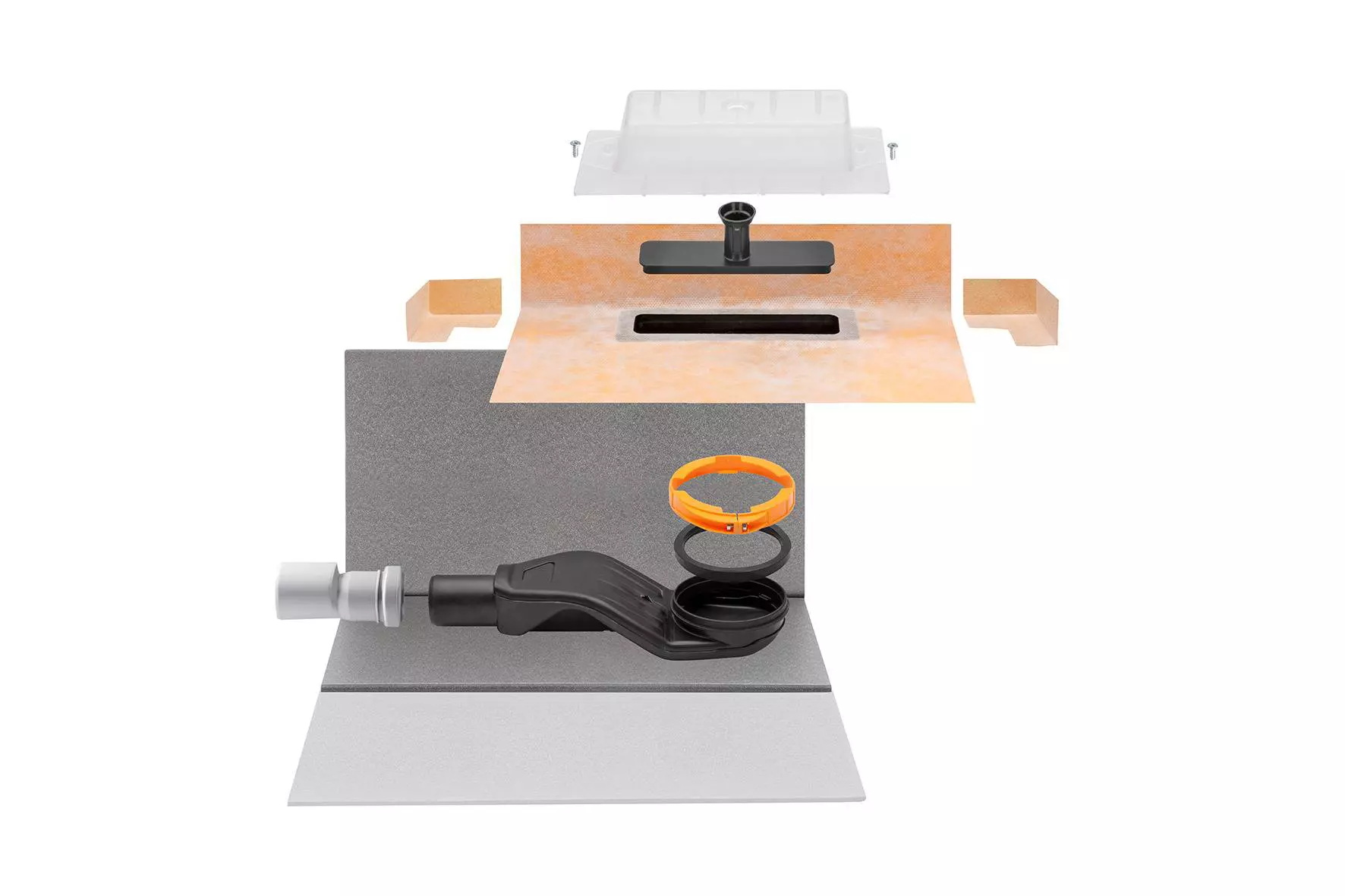

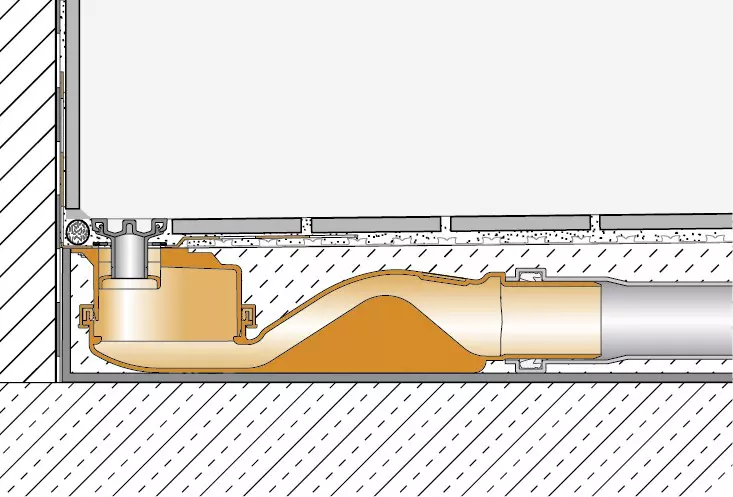

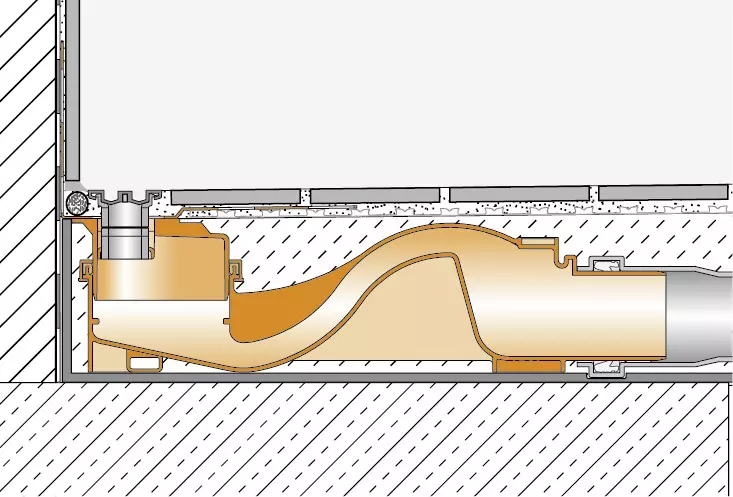

The two-piece horizontal KERDI-LINE-VARIO drain unit comprises a drain body and a drain adapter. The drain body consists of an ultra slim, wave-shaped drain that is rotatable by 360° and a built-in odour trap. The wave-shaped design achieves a high flow rate within the floor drain, which results in a self-cleaning effect.

The sound insulation membrane included in the set reliably prevents specific sound transmission of the drain body to the surrounding wall or floor structures and serves as a positioning aid for direct installation in a wall.

To guarantee an especially low assembly height, the drain adapter of KERDI-LINE-VARIO-H40 with integrated Schlüter-KERDI-FLEX collar comes fully inserted into the sealed wave-shaped drain and is secured with a clamping ring. The wave-shaped drain can be rotated by 360° when the clamping ring is released, which makes the drainage system adaptable to any connection configuration in the existing building.

The drain adapter of KERDI-LINE-VARIO-H50 can be individually cut to size to match the structural requirements on site.

The KERDI-LINE-VARIO-H set includes:

- Flat drain body with odour trap

- Drain adapter with integrated waterproofing collar and wave-shaped drain rotatable by 360

- Clamping ring

- Gasket

- Adapter DN 40/DN 50

- Protective lid for simple seal check

- Water inspection nozzle

- Corner seal

- Folding sound insulation element

- Spirit level to level the assembly

- Cleaning brushes, although the wave-shaped drain assembly prevents the accumulation of debris

Two design drainage profiles are available for KERDI-LINE-VARIO: KERDI-LINE-VARIO-COVE and KERDI-LINE-VARIO-WAVE. These can be individually cut to size, are height adjustable and are shipped with two matching end caps.

The pre-adhered elasticated KERDI collar integrated into the drain adapter ensures the reliable connection of the drain body to the bonded waterproofing assembly, both in the floor area and on upright walls. It is secured by a transparent protective lid during installation.

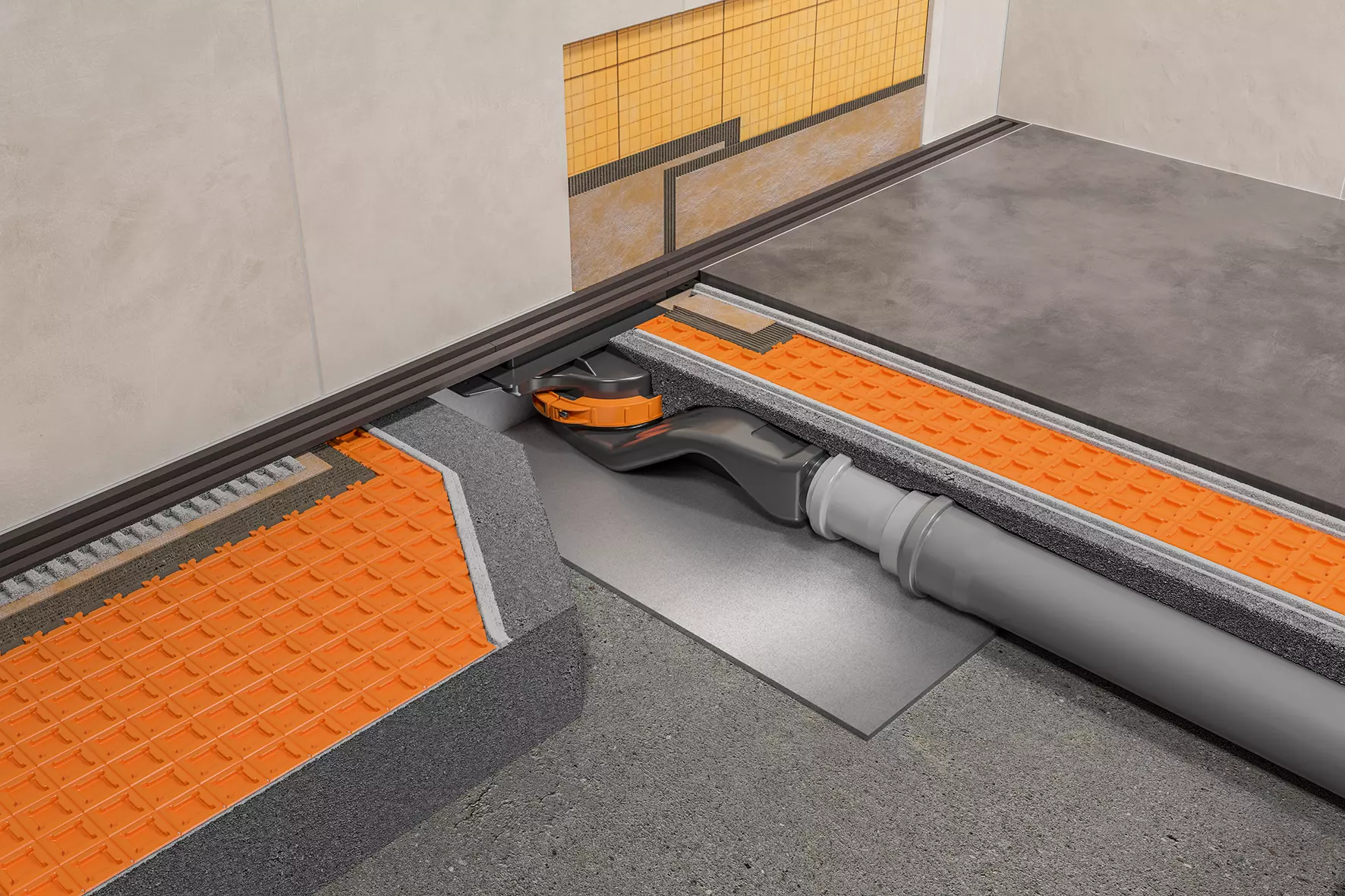

In conjunction with the waterproofing systems Schlüter-KERDI, Schlüter-DITRA, Schlüter-DITRA-HEAT or Schlüter-KERDI-BOARD and the matching system adhesives Schlüter-KERDI-COLL-L or Schlüter-KERDI-FIX, installers can create certified bonded waterproofing assemblies with connecting linear drainage. KERDI-LINE is a system component that complies with the German waterproofing standard DIN 18534. Together with the above-listed Schlüter-Systems it has general technical approval (abP) in Germany.

Please refer to the respective product data sheets for information about the moisture exposure classes according to abP. Schlüter-KERDI-LINE is a system component with European Technical Assessment (ETA) according to ETAG 022 (watertight covering kits). Schlüter products tested together with KERDI-LINE bear the CE mark.

Note:

Due to the variable drain construction, KERDI-LINE-VARIO requires the installation of a sloped screed. The surface of the screed must be waterproofed with DITRA (see product data sheet 6.1) or DITRA-HEAT (see product data sheet 6.4). Schlüter-SHOWERPROFILE-S and -R (see product data sheet 14.1) are supplementary components for creating a floor or wall connection. SHOWERPROFILE-S has a triangular design to conceal the sloped lateral edges of floor level showers. Waterproof the surrounding walls with KERDI (see product data sheet 8.1) or create a bonded waterproofing assembly with KERDI-BOARD (see product data sheet 12.1).

Soundproofing

For soundproofing as specified in DIN 4109, VDI 4100, ÖNORM B 8115-2 or SIA 181, the Schlüter-KERDI-LINE-SR sound insulation panel complies with impact sound, installation noise and user noise limits in certified assembly variants of KERDI-LINE-VARIO.