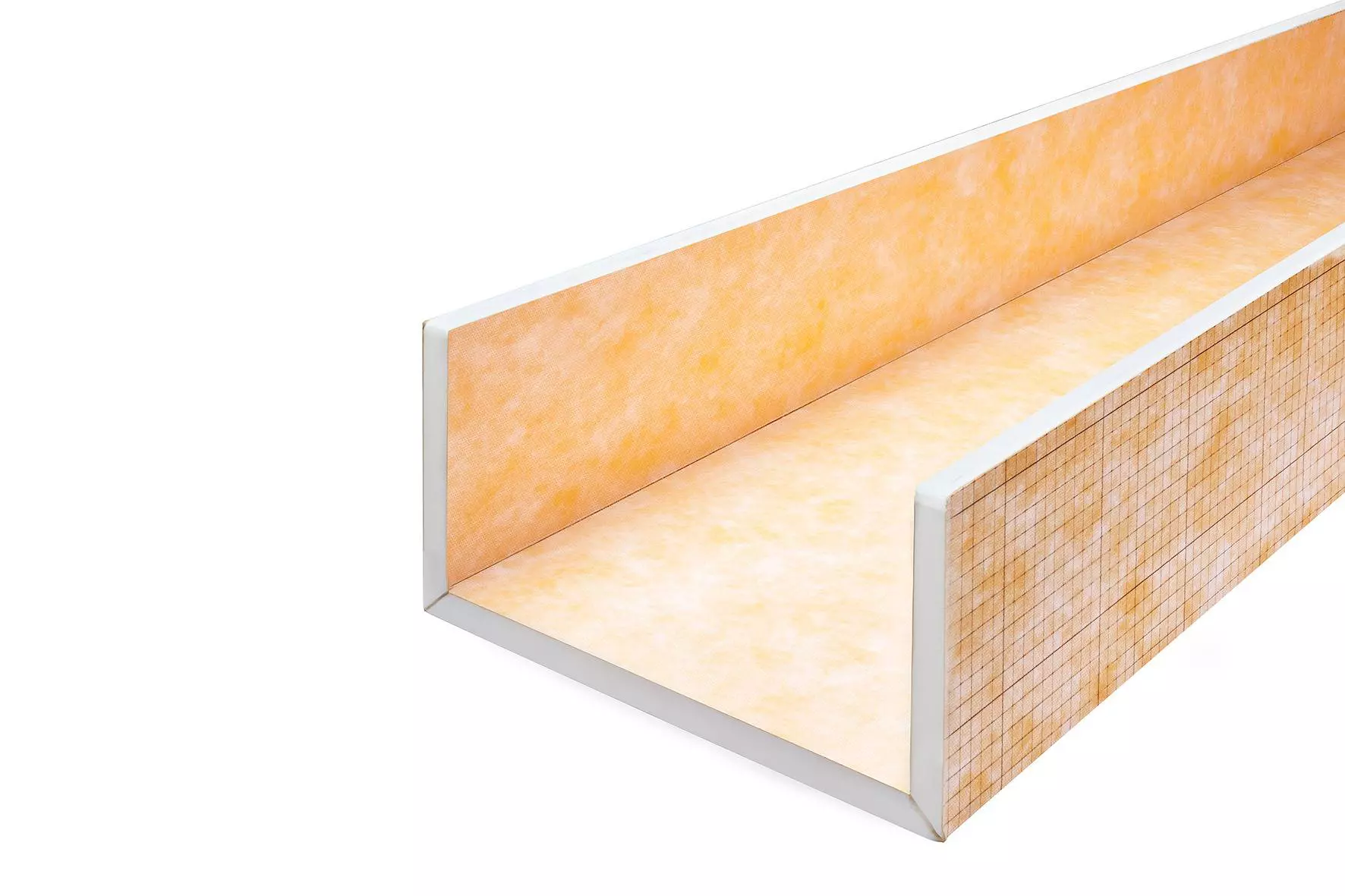

Schlüter-KERDI-BOARD is made of an extruded XPS rigid foam with a cement-free reinforcement layer and an anchoring fleece laminated on both sides. The upper face of the board is imprinted with 10 x 10 mm square gridlines.

Material properties and areas of application

Schlüter-KERDI-BOARD is waterproof and resistant to any chemical stresses that typically occur in conjunction with tiled coverings. Where required, a certified bonded waterproofing assembly can be created with KERDI-BOARD.

KERDI-BOARD is completely level and remains free of distortions and decay. It will not rot and is highly stable, even with

one side exposed to temperature fluctuations and moisture.

KERDI-BOARD is ideal for a wide variety of applications. Product suitability must be verified in applications exposed to chemical or mechanical stresses. The information provided below is intended as a general guideline.

Substrates on which KERDI-BOARD is to be installed must be checked for sufficient stability and other project-related requirements. If directly adhering the product, remove all surface components that may weaken the bond. Alternatively, the product can be fastened mechanically with the corresponding anchors or screws.

Select a sufficient material thickness for building free-standing partition walls, shelves etc. out of KERDI-BOARD. Reinforcement profiles may be needed.

In floor areas, the use of KERDI-BOARD is restricted to areas with foot traffic. Depending on the system, stepping on such coverings with hard shoes or tapping them with a hard object may produce a hollow sound.

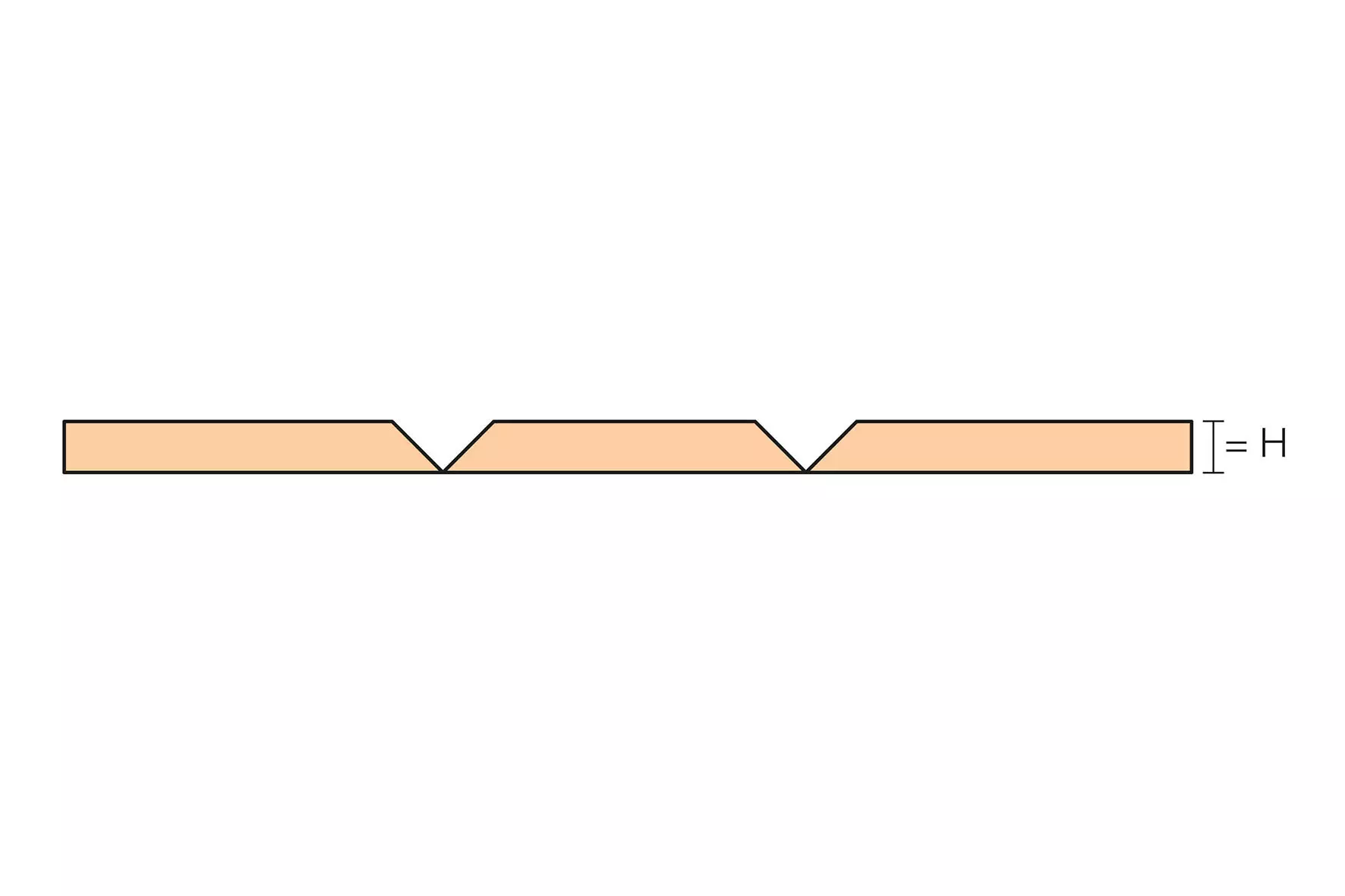

Select the material thickness and installation method according to the levelness of the substrate. Thin panels of KERDI-BOARD (5 mm) must be fully embedded in the adhesive.