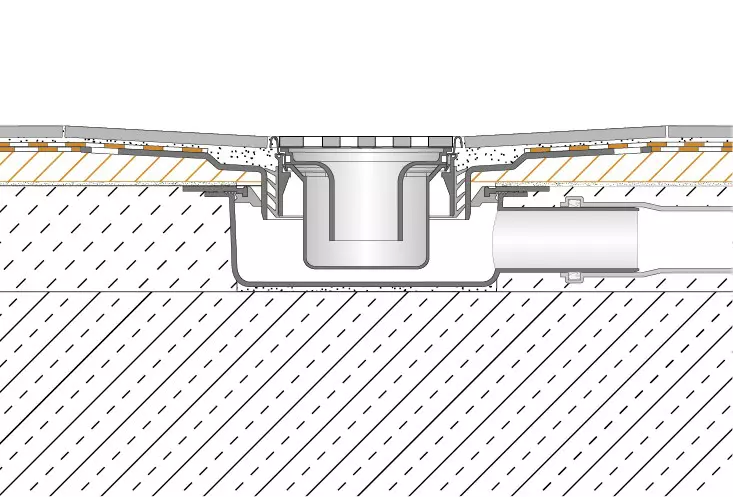

The sloped tray is made of compression-resistant expanded polystyrene (EPS).

The drain body is made of high-impact resistant polypropylene (PP).

The bonding flange is made of acrylonitrile butadiene styrene (ABS) and features an attachment flange with a fleece-coated surface.

The pre-adhered Schlüter-KERDI collar on the sloped tray is made of soft polyethylene with a special anchoring fleece laminated on the surface for effectively bonding with tile adhesive or adhesive products for other coverings.

The stainless steel grate included in the waterproofing set Schlüter-KERDI-SHOWER-SKB is made of V2A (material 1.4301 = AISI 304).

Material properties and areas of application

The drain body, bonding flange and covers are classified as K3 according to DIN EN 1253, Gullies for buildings. The classification K3 refers to areas without vehicle traffic, e.g. wetrooms in apartments, nursing homes, hotels, schools, and public washroom and shower facilities.

The suitability of a proposed floor drain system must be verified based on the anticipated chemical, mechanical and/or other stresses.