Schlüter-DITRA-SOUND is a bonded sound insulation assembly for tile coverings comprising a heavy duty polyethylene mat with an anchoring fleece laminated on both sides. The system was tested by an independent testing institute according to DIN EN ISO 140-8.

An impact sound improvement value (ΔLW) of 13 dB was measured in fully installed Schlüter-DITRA-SOUND assemblies.

The actual improvement offered by the respective assembly depends on the local conditions (structural design) and can deviate from this value. The measured test values therefore may not apply equally to every building situation.

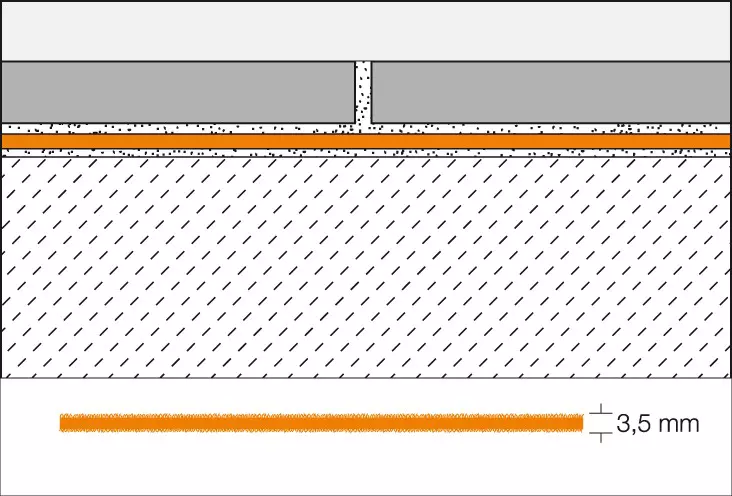

The substrate must be flat and load-bearing. Schlüter-DITRA-SOUND is installed in thin-bed tile adhesive that is suitable for the substrate, using a notched trowel (recommended size: 3 x 3 mm or 4 x 4 mm). The anchoring fleece on the underside (imprinted side) of Schlüter-DITRA-SOUND is fully embedded and the fabric bonds with the adhesive. The adhesive curing time must be observed.

The tile covering is installed directly over Schlüter-DITRA-SOUND in accordance with the applicable regulations, using the thin-bed method. The thin-bed tile adhesive bonds with the fleece layer on the top side of the mat. This creates a fully bonded system.

Impact sound/structural noise

The transmission of noise to adjacent rooms or lower floor levels, caused e.g. by walking or falling objects, is called impact sound. The structure borne sound causes vibrations in the floor/ceiling structure, which are then passed on as airborne sound.

The human ear perceives a 10 dB impact sound reduction as a 50% reduction of airborne sound.

In addition, the impact sound of e.g., hard shoes, echoes back into the room. This leads to unpleasant reverberations in light structures with hard surfaces, the so-called drum effect. The solid mass of the heavy duty mat prevents this effect.

Summary of functions

a) Sound insulation/structural noise insulation

In addition, the heavy duty mat material absorbs structural noises, e.g. those caused by footsteps, and helps reduce the drum effect.

The insulation panel is especially suited for renovation or remodeling projects as well as new construction.

The low assembly height of approx. 3.5 mm and the excellent sound insulation values of Schlüter-DITRA-SOUND make it an ideal choice for renovation and remodeling projects.

b) Crack-bridging

Cracks that are only expected to widen slightly without height displacement may be covered with Schlüter-DITRA-SOUND to prevent cracks in the substrate from continuing into the tile covering. If necessary, add an insert to prevent vertical height displacement.

c) Load distribution (load induction)

Schlüter-DITRA-SOUND is a compression-resistant heavy duty mat. That makes tile coverings installed on Schlüter-DITRA-SOUND especially durable. The tiles for the corresponding application area must be sufficiently thick and have adequate compressive stability to withstand high traffic loads (max. 5 kN/m², e.g. in commercial areas). The information and tile thicknesses specified in the ZDB information sheet "Ceramic floor coverings with high mechanical stress resistance", valid in Germany, must be observed.

Carefully ensure that tiles in high-stress areas are solidly embedded in the tile adhesive.

The impact of hard objects should be avoided on ceramic coverings.

Tile dimensions should be at least 5 x 5 cm.