- Always check the substrates on which DITRA-HEAT-PS is to be installed to make sure they are flat, load bearing, clean and compatible with the materials to be used. Remove all surface components that may weaken the bond. Any levelling, height adjustment or slope compensation must be carried out before the installation.

- Thoroughly vacuum the substrate prior to installation to remove all dust.

Note:

Although it is not mandatory to apply a primer, if the condition of the substrate necessitates it, a primer suitable for the substrate should be used.

- Cut the uncoupling mat DITRA-HEAT-PS to size and lay it out on the floor. Now remove the release film from the fleece on the underside and press the mat evenly on the substrate, using a float or roller.

Note:

For efficient installation of product rolls, precisely align DITRA-HEAT-PS and keep the material tightly stretched with light tension when placing it on the substrate. Minor repositioning is possible before pressure is applied to the uncoupling mat.

The EasyCut gridlines of the membrane minimise the curling memory.

To prevent any damage to the installed DITRA-HEAT-PS material or detachment from the substrate, protect the area from mechanical stresses, e.g. by setting out running boards (particularly in the centre areas used for material transport).

Installation of electrical Schlüter-DITRA-HEAT-E components

The electrical installation must be performed by a qualified electrician in accordance with BS7671.

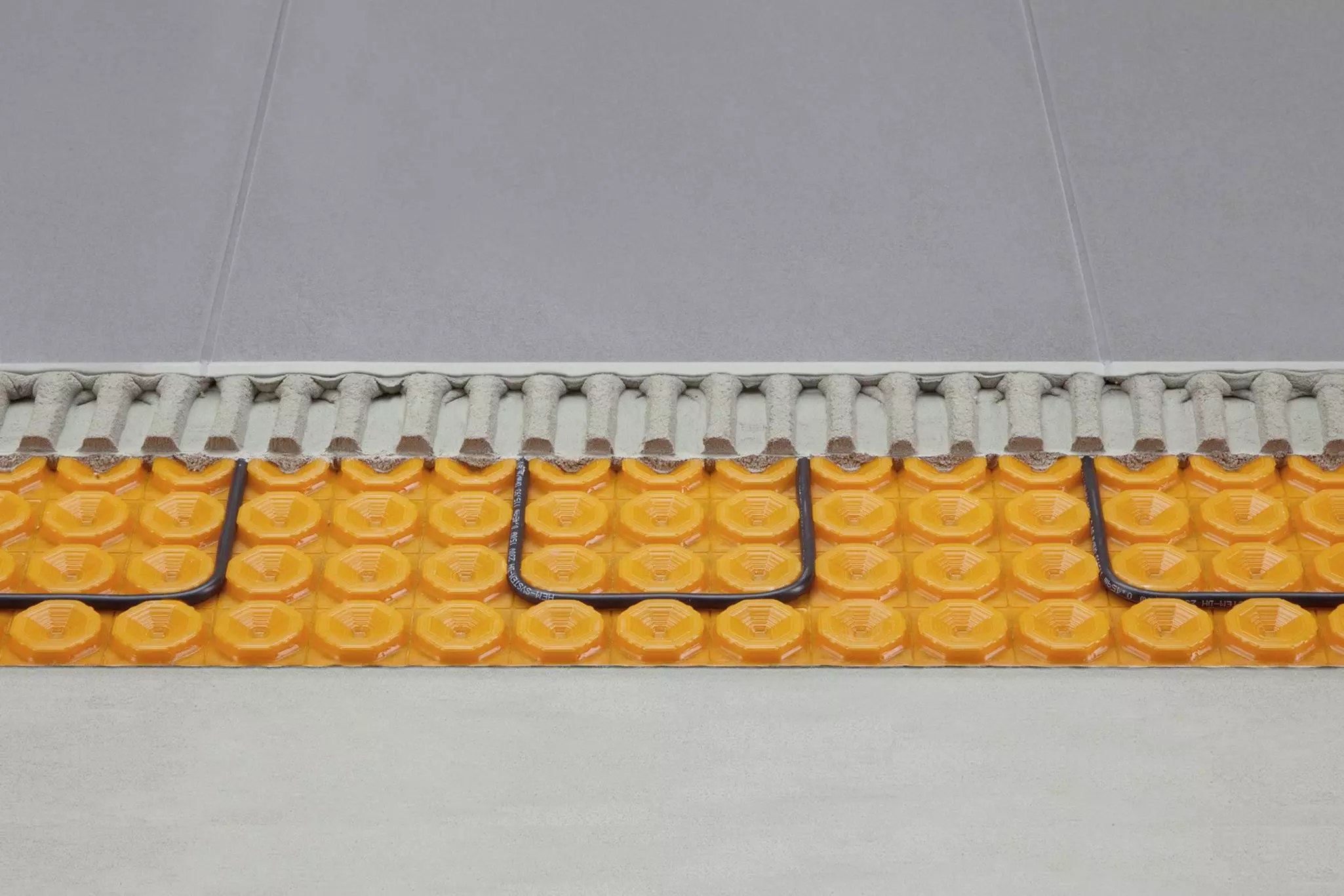

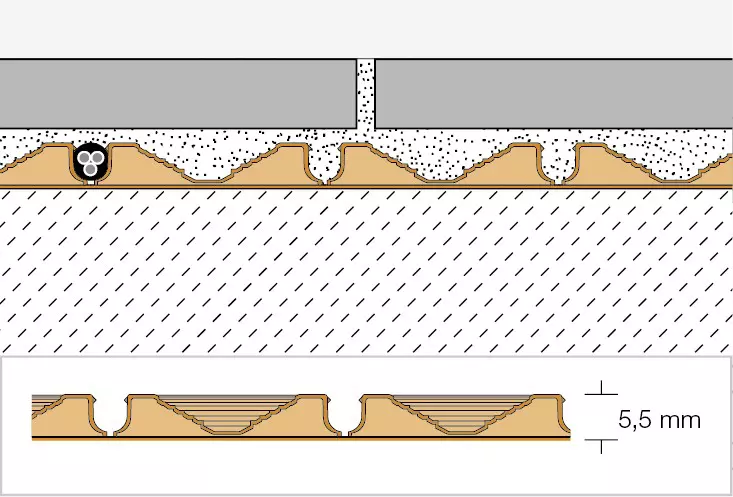

- The heating cables may be installed immediately after adhering the uncoupling mat DITRA-HEAT-PS, using a float or roller. Create a corresponding indentation in the area of the sealed cable end.

- Install the floor sensors directly in the adhered uncoupling mat DITRA-HEAT-PS. Since the floor sensor is embedded directly in the cementitious tile adhesive and cannot be replaced, the installation must include a spare sensor (a 2nd sensor is included in thermostat scope of supply as a spare sensor). Place the sensors in the centre between two heating cable loops.

Note: Before embedding the sensors with cementitious tile adhesive, measure the resistance values, e.g. with the cable tester DITRA-HEAT-E-CT, and compare them with the values listed in the thermostat installation instructions.

Further information on the installation and settings of electrical components of the Schlüter-DITRA-HEAT-E family can be found in the supplied installation instructions or product data sheets.

If the DITRA-HEAT-PS assembly is to be used for floor heating, follow the recommendations in the installation instructions for Schlüter-DITRA-HEAT-E.

Waterproofing with Schlüter-DITRA-HEAT-PS

Unless a certified bonded waterproofing assembly is required, DITRA-HEAT can serve as a waterproofing layer, provided the abutting membrane seams and the connections to installed components and upright building structures are carefully sealed.

If national technical approval (abP) or European approval (ETA = European Technical Assessment) is needed, choose the variants of DITRA-HEAT/-DUO for installation with cementitious tile adhesive that have the corresponding certification.

DITRA-HEAT-PS protects the substrate from damage caused by permeating moisture and aggressive substances. For sealing joints, trowel the sealing adhesive Schlüter-KERDI-COLL-L over the abutting joints and embed the sealing band Schlüter-KERDI-KEBA in a minimum width of 12.5 cm over the joints.

To waterproof floor-wall transitions, adhere KERDI-KEBA over DITRA-HEAT-PS on the floor and directly on the substrate in wall areas in the corresponding width. The sealing band must have a coverage of at least 5 cm. KERDI-KEBA can also be used to create functional connections to fixed structural components such as door and window frames made of metal, wood or plastic. The first step is to apply Schlüter-KERDI-FIX to the adhesive surfaces of the structural elements. The remaining width is then adhered to DITRA-HEAT-PS with KERDI-COLL-L.

The suitability of KERDI-FIX for the respective materials of the structural elements must be verified in advance. Separate DITRA-HEAT-PS at existing movement joints or expansion joints and seal the abutting joints with Schlüter-KERDI-FLEX. Never run heating cables over expansion joints or dummy joints.

KERDI-FLEX should also be used for flexible finishing edges. As an alternative, this can also be done with a sufficient loop of KERDI-KEBA.

Substrates for Schlüter-DITRA-HEAT-PS

Always check that the substrates on which DITRA-HEAT-PS is to be installed are level, load bearing, clean and compatible with the materials to be used. Remove all surface components that may weaken the bond. Any levelling, height adjustment or slope compensation must be carried out before installing DITRA-HEAT-PS.

To guarantee effective floor heating, heat insulation is required, especially for installations adjoining soil or unheated spaces.

We recommend using DITRA-HEAT-DUO-PS for a faster heat-up response on unheated screed assemblies.

DITRA-HEAT-PS can only be installed on building components adjoining soil that have proper waterproofing to protect against rising moisture or water pressure. A functional horizontal barrier must be in place.

Concrete

Concrete undergoes long-term structural deformation due to shrinkage. In addition, tension can build up in concrete and pre-stressed concrete due to deflection.

Since DITRA-HEAT-PS absorbs the resulting tensions between the concrete and the tile covering, tiles can be installed about 28 days after pouring the concrete.

Cement screeds

Cement screeds must have cured for at least 28 days prior to tile installation in accordance with the applicable regulations and have a moisture content below 2 CM %.

Floating and heated screeds have a particular tendency to buckle and crack even later, e.g. due to mechanical stresses and temperature fluctuations. With DITRA-HEAT-PS, tiles can be installed on fresh cement screeds as soon as their surface is sufficiently dry (typically this takes approx. 3-5 days for well ventilated standard cement screeds).

DITRA-HEAT-PS will neutralise cracks and screed deformations developing later and will prevent them from affecting the tile covering.

Gypsum based screed

According to the applicable rules, gypsum based (anhydrite) screed may not have a residual moisture level of more than 0.5 CM % at the time of tile installation. In contrast, tile installation is permissible from a residual moisture level of 2 CM % with DITRA-HEAT-PS.

If necessary, the screed surface must be treated (grinding, priming) as specified by the applicable technical regulations and manufacturer instructions. DITRA-HEAT-PS can then be adhered to the pre-treated screed surface. DITRA-HEAT-PS protects the screed surface against permeating moisture. Because gypsum based screeds are susceptible to moisture, the screed must be protected against humidity, e.g. moisture seepage on the underside.

Heated screeds

DITRA-HEAT-PS can be used on heated screeds, provided the above notes (cement, gypsum based screeds) are followed. Covering assemblies created with DITRA-HEAT-PS are ready for heating only 7 days after completion. Starting from a temperature of 25 degrees C, the supply temperature can be increased by no more than 5 degrees C a day to a maximum of 40 degrees C.

Note:

Installing DITRA-HEAT-PS over heated screeds makes it feasible to operate an individual, partial heating system that is independent of the central heating system. This allows for completely turning off the central heating system during seasonal transition times.

DITRA-HEAT-PS assemblies can also cover peak loads.

Vinyl coverings and coatings

All surfaces must be load bearing and pre-treated or suitable for bonding with the adhesive anchoring fleece on the underside of DITRA-HEAT-PS. The compatibility of the adhesive with the substrate must be verified in advance. DITRA-HEAT-PS may only be installed on substrates that are free of solvents, plasticisers and oils.

Plywood, chipboard and compressed wood panels

These materials are especially prone to form changes when exposed to moisture (or heavily fluctuating humidity levels). It is therefore recommended to use plywood, chipboard and compressed wood panels with special water-repellent treatment to protect against moisture.

Such panels can generally be used as a floor substrate in interior spaces. However, they have to be thick enough to be sufficiently stable in conjunction with a suitable support assembly.

The structure should be fastened with closely spaced screws. Abutments must have a tongue and groove connection and be fully sealed. Perimeter movement joints of about 10 mm have to be maintained at the transition to upright building structures. DITRA-HEAT-PS neutralises any tensions with the tile covering and also prevents permeating moisture.

Hardwood floors

In principle, ceramic coverings can be installed on sufficiently weight bearing hardwood floors with tongue and groove connections. It has been proven beneficial to install an additional layer of plywood. The wooden substrate should have balanced moisture levels before DITRA-HEAT-PS can be installed. Uneven floor surfaces should be levelled with suitable measures beforehand.